Fiber fabric reinforced polyarylether sulfone composite material and preparation method thereof

A technology of fiber fabric and polyarylethersulfone, which is applied in the field of polymer composite materials, can solve problems such as infirmity, increased fiber wool rate, and low production efficiency, and achieve good thermal properties, good mechanical properties, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

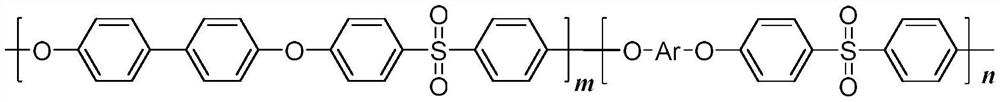

[0020] Dissolve polyaryl ether sulfone resin in benzyl alcohol, configure a solution with a mass concentration of 20%, pour it into the dipping tank, and make the surface density 380g / m 2 , Basalt fiber cloth with a width of 1m is dipped in a glue tank for 6 minutes, the excess glue is removed by a scraping roller, and the solvent is removed in a hot oven at 180°C / 15min+220°C / 15min+250°C / 20min to obtain a prepreg sheet. Cut the prepreg sheet according to the size of the mold, stack 6 layers into the mold, heat up the hot press slowly to 350°C, and hold the pressure at 10MPa for 20 minutes to obtain fiber fabric reinforced polyarylethersulfone composite laminates, fiber fabric The volume fraction is 65%. The tensile strength of the fiber fabric reinforced polyarylethersulfone composite is 683MPa (test standard GB / T 3354-2014), T g = 246°C. The structure of polyarylethersulfone resin is as follows: m=0.6, n=0.4

[0021]

Embodiment 2

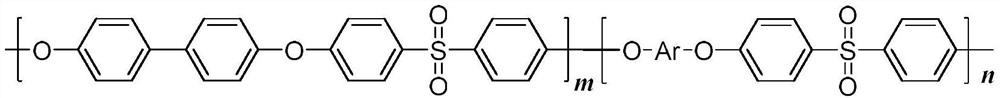

[0023] Dissolve polyaryl ether sulfone resin in acetophenone, configure a solution with a mass concentration of 35%, pour it into the dipping tank, and adjust the surface density to 260g / m 2 1. The glass fiber cloth with a width of 80cm is dipped in the glue tank for 10min, the excess glue is removed by the scraping roller, and the solvent is removed in the heating tunnel at 180°C / 10min+210°C / 10min+250°C / 20min to obtain the prepreg sheet. Cut the prepreg sheet according to the size of the mold, stack 10 layers into the mold, heat up the hot press slowly to 360°C, and hold the pressure at 8MPa for 30 minutes to obtain a fiber fabric reinforced polyarylethersulfone composite laminate, the volume of the fiber fabric The score is 40%. The tensile strength of the fiber fabric reinforced polyarylethersulfone composite is 479MPa (test standard GB / T 3354-2014), T g = 251°C. The structure of polyarylethersulfone resin is as follows: m=0.5, n=0.5

[0024]

Embodiment 3

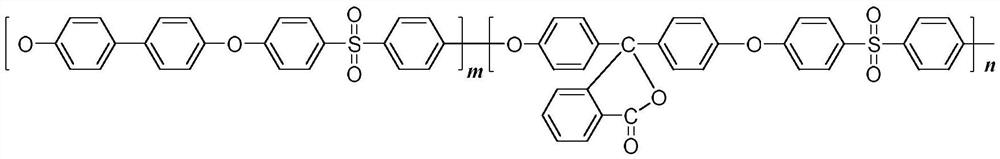

[0026] Dissolve polyaryl ether sulfone resin in cyclohexanone, configure a solution with a mass concentration of 25%, pour it into the dipping tank, and adjust the surface density to 160g / m 2 1. A carbon fiber cloth with a width of 1m is dipped in a glue tank for 8 minutes, the excess glue is removed by a scraping roller, and the solvent is removed in a heating tunnel at 160°C / 10min+200°C / 10min+250°C / 10min to obtain a prepreg sheet. Cut the prepreg sheet according to the size of the mold, stack 16 layers into the mold, heat up the hot press slowly to 380°C, and hold the pressure at 15MPa for 40 minutes to obtain a fiber fabric reinforced polyarylethersulfone composite laminate, the volume of the fiber fabric The score is 60%. The tensile strength of the fiber fabric reinforced polyarylethersulfone composite material is 958MPa (test standard GB / T 3354-2014), T g = 249°C. The structure of polyarylethersulfone resin is as follows: m=0.3, n=0.7

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com