Multi-level phase change composite material and preparation method and application thereof

A phase change composite material and a phase change material technology, which are applied in the field of multi-level phase change composite materials and their preparation, can solve limited problems, and achieve the effects of improving low temperature resistance, enhanced thermal conductivity, and high load rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

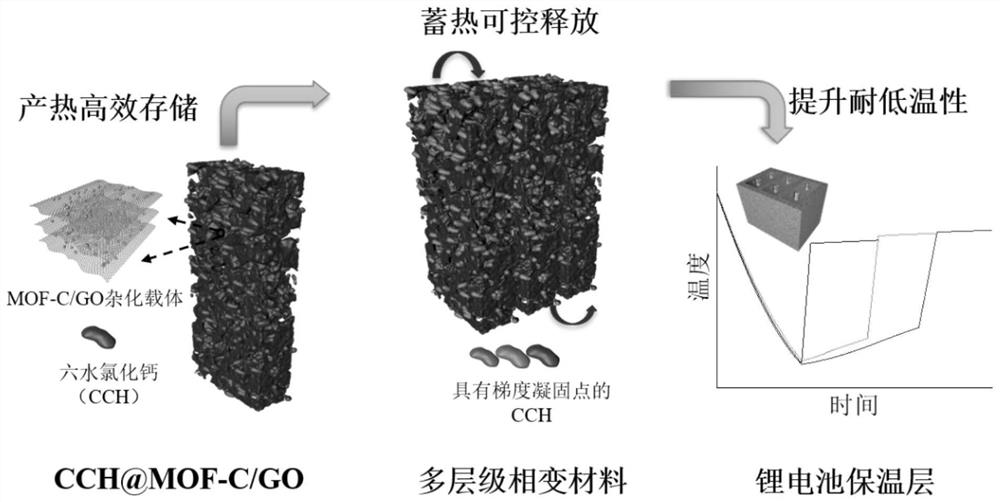

[0036] In order to solve the above problems, combined with figure 1 As shown, the embodiment of the present invention provides a method for preparing a multi-level phase change composite material, comprising the following steps:

[0037] S1. Disperse ferric chloride hexahydrate and trimesic acid in water, stir evenly to obtain a mixed solution, place the mixed solution in a reactor for hydrothermal reaction, and obtain a solid product organometallic framework MIL-100(Fe), and The solid product is subjected to high-temperature carbonization treatment to obtain MOF-based carbide MOF-C;

[0038] S2. The graphene oxide is formulated into a water-based dispersion, and MOF-based carbide and a crosslinking agent are added, hydrothermally synthesized and freeze-dried to obtain an airgel carrier;

[0039] S3, heating and melting calcium chloride hexahydrate and adding a nucleating agent to obtain a variety of phase change materials with different freezing points;

[0040] S4. Immerse...

Embodiment 1

[0060] This embodiment provides a method for preparing a multi-level phase change composite material, comprising the following steps:

[0061] 1) Weigh 1mmol ferric chloride hexahydrate and 0.66mmol trimesic acid into 20mL deionized water and stir magnetically at room temperature for 10min, dissolve completely to obtain an orange-yellow clear liquid; place the resulting mixture solution in 50mL polytetrafluoroethylene In a lined reaction kettle, heat at 120°C for 72h for hydrothermal reaction to obtain an orange-yellow solid precipitate; treat the solid precipitate at 500°C in a nitrogen atmosphere for 1h to obtain black MOF-C powder;

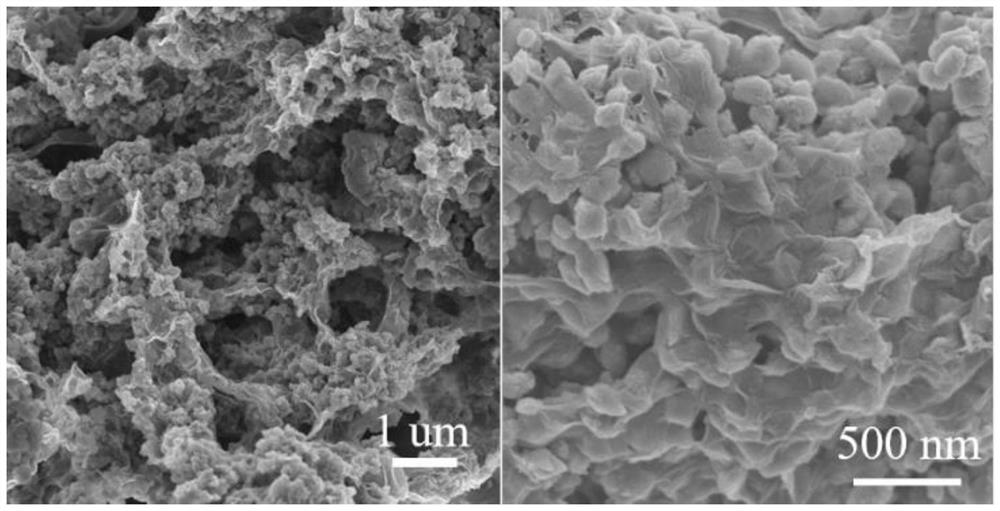

[0062] 2) Weigh GO to prepare 5 mL of aqueous dispersions with different concentrations, add 10 mg of MOF-C powder and 20 μL of cross-linking agent EDA, heat at 180 °C for 12 h for hydrothermal synthesis, and obtain MOF-based carbide / graphite oxide after freeze-drying ene hybrid airgel carrier;

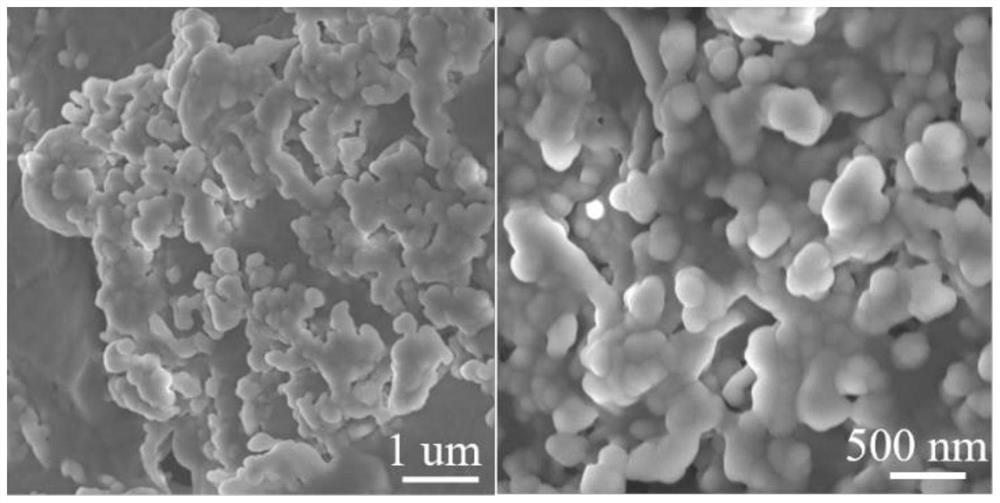

[0063] 3) Weigh a certain amount of calcium chl...

Embodiment 2

[0069] This embodiment provides a method for preparing a multi-level phase change composite material, the difference from Embodiment 1 is:

[0070] In step 1), the solid precipitate was treated in a nitrogen atmosphere at 600°C for 30 minutes to obtain black MOF-C powder;

[0071] All the other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com