Thermocouple insulating material moisture-absorption-preventing high-temperature sealing material and preparation method thereof

A technology of insulating materials and sealing materials, which is used in thermometers, thermometers, and heat measurement of electrical/magnetic components that are directly sensitive to heat, which can solve problems such as large limitations, moisture absorption failure, and poor temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

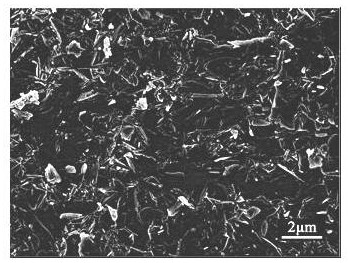

[0031] The preparation method of the high-temperature sealing material for preventing moisture absorption of the thermocouple insulating material comprises:

[0032] Step 1, mixing the glass micropowder and terpineol evenly according to a certain mass ratio;

[0033] Step 2, using an agate mortar to grind the mixed powder in step 1 finer;

[0034] Step 3: Weighing the medium-weight mixed powders of Step 2 and placing them in a tablet press for press molding respectively to prepare a sealing material block.

[0035] Step 4: Thread the thermocouple wire into the block sealing material obtained in Step 3, then thread the combination of the thermocouple wire and the block sealing material into the stainless steel casing, connect it to the compensation wire at the end of the probe, and then heat it at high temperature. After the high-temperature glass sealing work is completed, it can be moderately crystallized through the glass heat treatment process in the later stage to form a ...

Embodiment

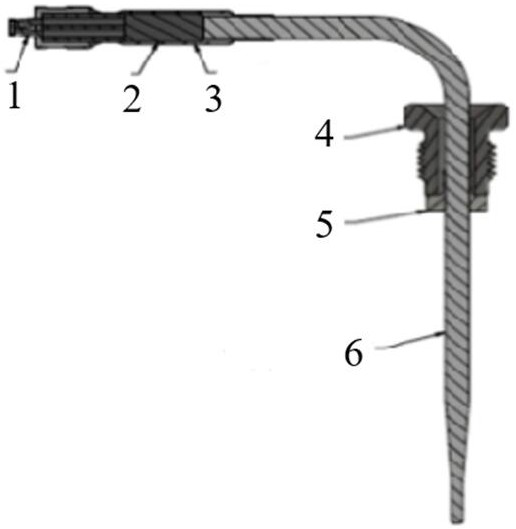

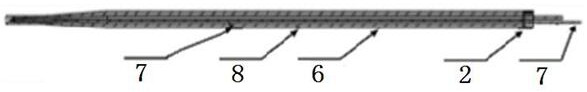

[0038] figure 1 It is a structural schematic diagram of an armored thermocouple, which shows the shapes and relative positions of the glass sealing material, the metal couple wire and the ferritic stainless steel casing in the present invention. The armored thermocouple is a thermocouple metal couple wire, a ceramic filling material, a glass sealing material and an alloy sleeve, and the glass sealing material of the present invention is used for sealing between the magnesium oxide powder and the ferritic stainless steel sleeve, and then applied Appropriate heat treatment process is used to draw and produce armored thermocouples of different specifications. Using glass powder as the sealing material can ensure the reliable insulation of the magnesium oxide powder in the armored thermocouple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com