Mildew-proof microcapsule for bamboo wood and preparation method of mildew-proof microcapsule

A microcapsule and anti-mildew technology, which is applied in the direction of microcapsule preparation, microsphere preparation, wood treatment, etc., can solve the problems that organic fungicides cannot be uniformly dispersed, cannot protect bamboo and wood for long-term protection, and is easy to hydrolyze and photolyze. Narrow distribution index, industrialized production and application, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

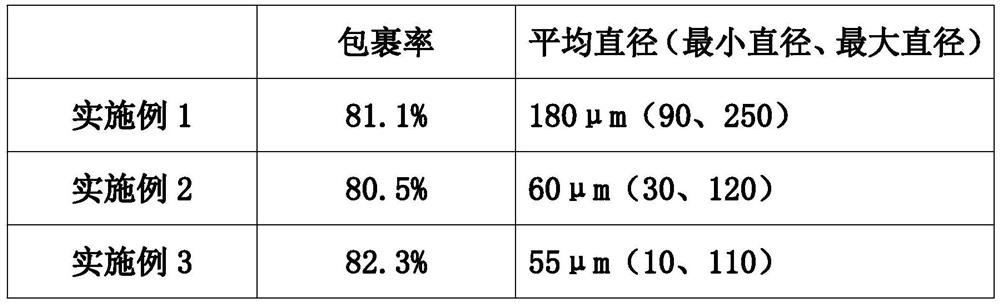

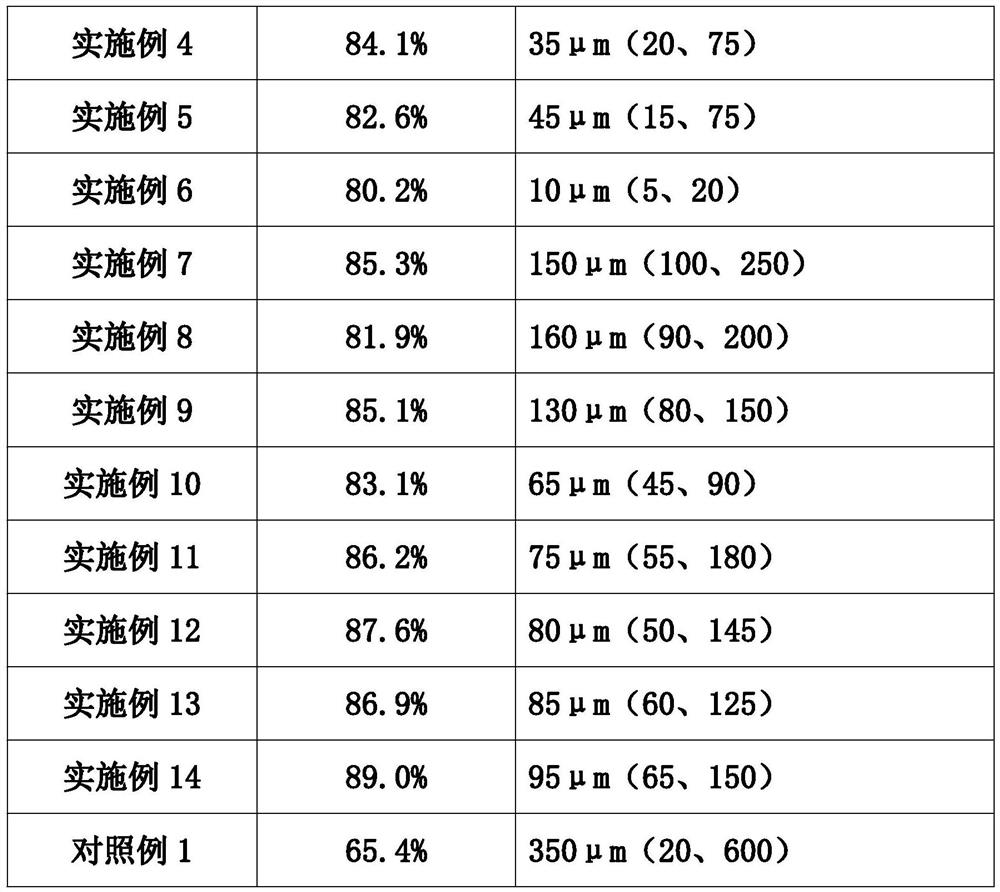

Examples

Embodiment 1

[0030] Embodiment 1: a kind of mildew-proof microcapsule for bamboo, comprising by mass parts:

[0031] Core material 1g, wall material 1g, emulsifier 0.8g, dispersant 0.5g, acid catalyst 0.4g; Described emulsifier is styrene-maleic anhydride emulsion, and described dispersant is polyvinyl alcohol, and described acid catalyst is acetic acid;

[0032] The core material includes the following components in parts by weight: 3 g of a triazole fungicide, 0.9 g of an organic solvent; the triazole fungicide is tebuconazole, and the organic solvent is toluene;

[0033] The wall material is amino resin, and the amino resin is urea-formaldehyde resin.

[0034] Carry out the preparation of mildew-proof microcapsules according to above-mentioned raw material, its step is as follows:

[0035] S1, mixing triazole fungicides and organic solvents at a temperature of 20-40°C to obtain core materials;

[0036] S2. After mixing the core material and the emulsifier in the amino resin, add a di...

Embodiment 2

[0038] Embodiment 2: a kind of mildew-proof microcapsule for bamboo, comprising by mass parts:

[0039] Core material 1g, wall material 2g, emulsifier 1.3g, dispersant 0.8g, acid catalyst 0.8g; Described emulsifier is sodium lauryl sulfate, and described dispersant is polyethylene glycol, and described acid catalyst is citric acid;

[0040] The core material includes the following components in parts by weight: 6 g of triazole fungicide, 1.2 g of organic solvent; the triazole fungicide is propiconazole, and the organic solvent is ethanol;

[0041] The wall material is amino resin, and the amino resin is urea-formaldehyde resin.

[0042] Carry out the preparation of mildew-proof microcapsules according to above-mentioned raw material, its step is as follows:

[0043] S1. Mix and stir a triazole fungicide and an organic solvent at a temperature of 20-40° C. to obtain a core material;

[0044] S2. After mixing the core material and the emulsifier in the amino resin, add a disp...

Embodiment 3

[0046] Embodiment 3: a kind of mildew-proof microcapsule for bamboo, comprising by mass parts:

[0047] Core material 1g, wall material 2.5g, emulsifier 0.8g, dispersant 1g, acid catalyst 0.5g; Described emulsifier is the combination of sodium lauryl sulfate and polyoxyethylene octylphenol ether-10, both mass The ratio is 1:1, the dispersant is sodium polyacrylate, and the acidic catalyst is potassium hydrogen phthalate solution;

[0048] The core material includes the following components in parts by weight: 5 g of a triazole fungicide, 1 g of an organic solvent; the triazole fungicide is diniconazole, and the organic solvent is acetone;

[0049] The wall material is amino resin, and the amino resin is urea-formaldehyde resin.

[0050]Carry out the preparation of mildew-proof microcapsules according to above-mentioned raw material, its step is as follows:

[0051] S1. Mix and stir a triazole fungicide and an organic solvent at a temperature of 20-40° C. to obtain a core mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com