Method for promoting anaerobic co-fermentation of cow dung and straw

A cow dung straw, co-fermentation technology, applied in fermentation, biological sludge treatment, waste fuel and other directions, can solve the problems of long fermentation cycle, difficult to start direct anaerobic fermentation, etc., to improve the methane content, shorten the fermentation cycle, promote The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

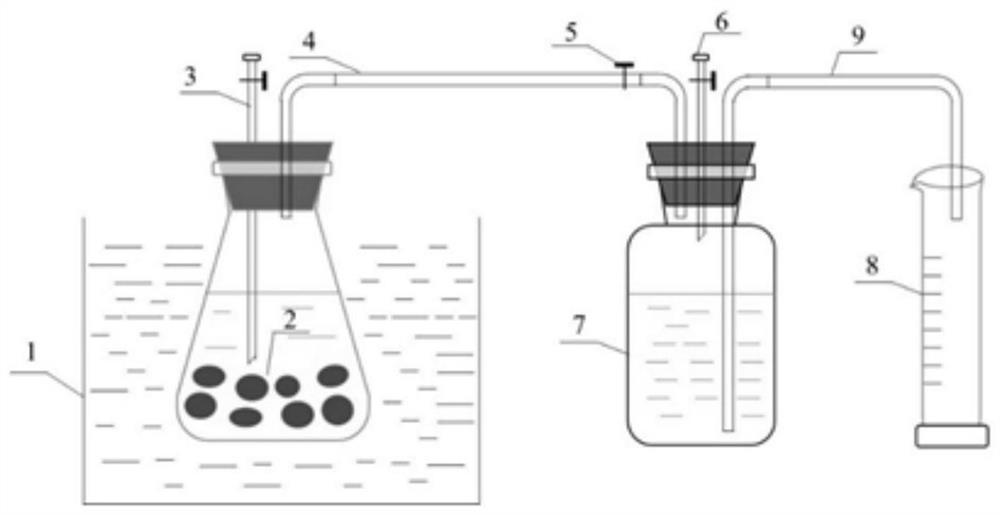

[0043] Adopt 500mL Erlenmeyer flask as reactor, seal by rubber stopper and glass glue, reaction device such as figure 1 shown.

[0044] 1. Preparation of alkaline biogas slurry:

[0045] The above-mentioned cow dung and corn stalks were mixed for anaerobic co-fermentation at a ratio of 9:1, with diatomaceous earth as an additive, and the addition amount was 8% of the total solid content of cow dung and corn stalks. After the acidification stage ended (the 7th day) Add an appropriate amount of sodium bicarbonate (30mL), adjust the pH value of the system to neutral (pH=7), and introduce EM bacterial liquid (EM bacterial liquid was purchased from Anhui Guangyu Biotechnology Co., Ltd.; Bacteria, Bacillus, Enterococcus faecalis and acetic acid bacteria), the addition amount is 10% of the total mixture mass, and alkaline biogas slurry is obtained at the end of anaerobic fermentation (28 days).

[0046] 2. Co-fermentation of cow dung and corn straw:

[0047]First, soak corn stalks...

Embodiment 2

[0052] The gas production performance of embodiment 2 anaerobic fermentation system

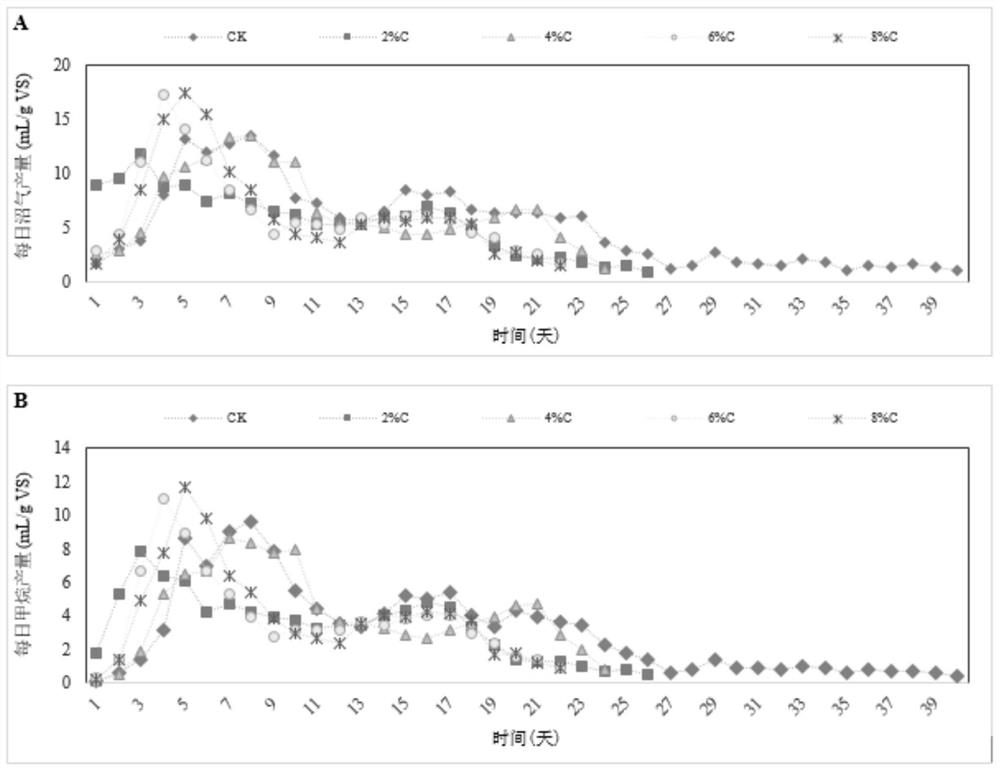

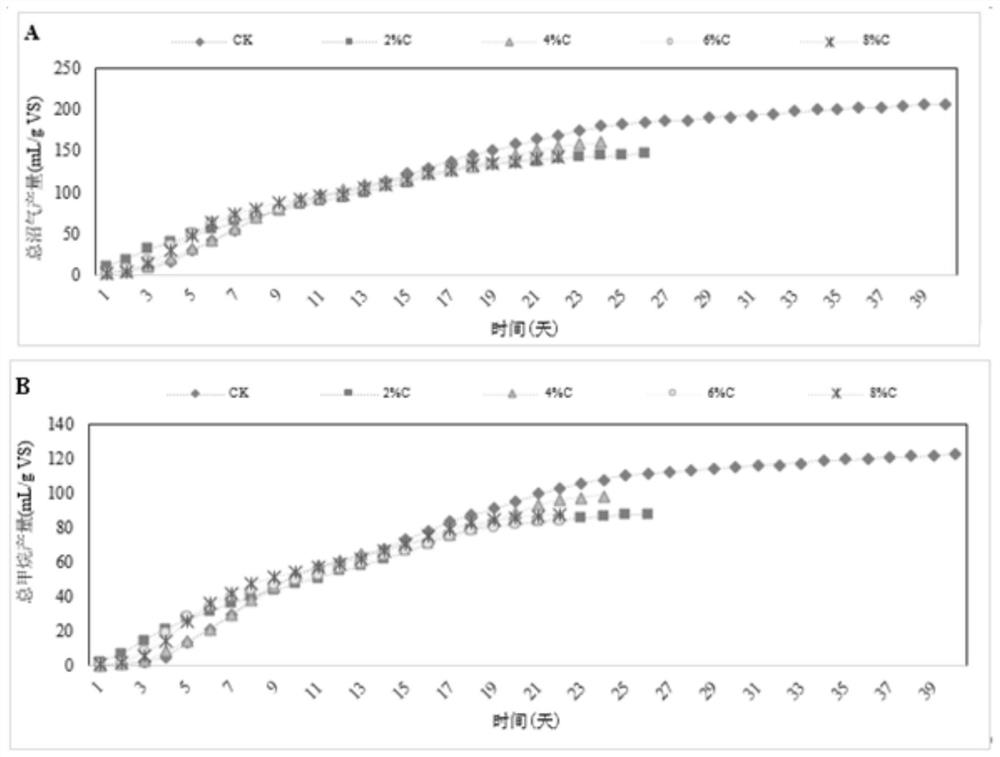

[0053] figure 2 It is the graph of daily biogas production and daily methane production, among which, graph A is the daily biogas production, and graph B is the daily methane production.

[0054] Depend on figure 2 A It can be seen that the maximum single-day gas production of the biochar group is 8% C, and the gas production is 17.48mL / g VS on the fifth day. From the perspective of the gas production cycle, the anaerobic fermentation cycle was significantly shortened after the addition of biochar: the blank control group without biochar ended on the 40th day of anaerobic fermentation, and the biochar group reacted on the 22nd to 26th day of reaction. Finish. Adding 6% and 8% biochar had the most obvious effect on shortening the period, both of which ended on the 22nd day, and adding 2% biochar ended on the 26th day, which also had a more obvious effect of promoting the rate of anaerobic...

Embodiment 3

[0061] pH and conductivity of embodiment 3 anaerobic fermentation system

[0062] Figure 5 is the change of pH in the anaerobic fermentation system. From the perspective of pH, 30mL of saturated sodium bicarbonate was added to the CK group to increase the pH from 5.33 to 7.03 neutral. On the seventh day, it reached a phased maximum pH of 7.5, and at the same time reached the peak of gas production on the seventh day, reaching the gas production The pH gradually decreased after the peak, reaching 7.18 on the 16th day. Finally, at the end of the anaerobic fermentation reaction, it gradually increased to 8.26. Because the pH was too high, it was not conducive to the growth of methanogens, and the anaerobic fermentation gas production ended. The pH of the experimental group eventually approached 6.8. Since the biochar experimental group added alkaline biogas slurry containing methanogenic bacteria, it was easier to promote the system start-up after being added to the system. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com