Self-supporting porous carbon fiber material as well as preparation method and application thereof

A porous carbon fiber, self-supporting technology, applied in separation methods, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of small specific surface area of capacitive deionization electrodes, limited heavy metal ion adsorption capacity, low electric double layer capacitance, etc. , to achieve the effect of excellent cycle life, high capacitance capacity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

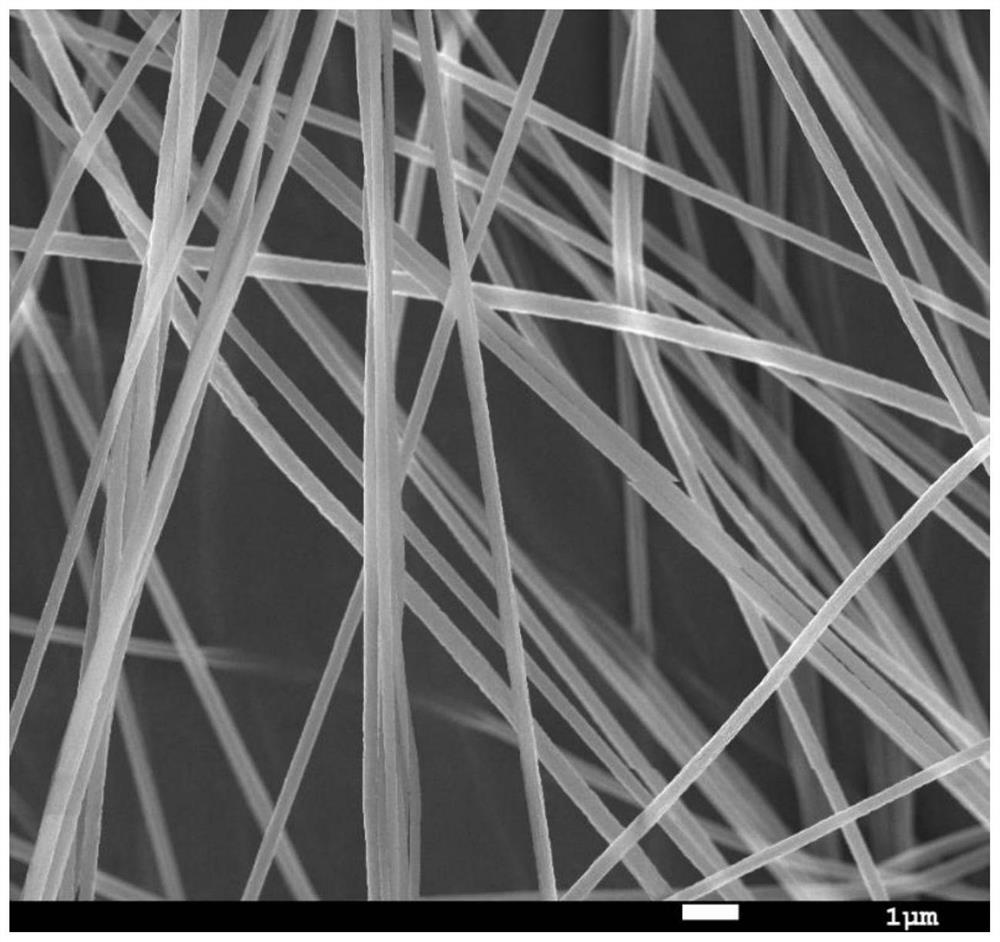

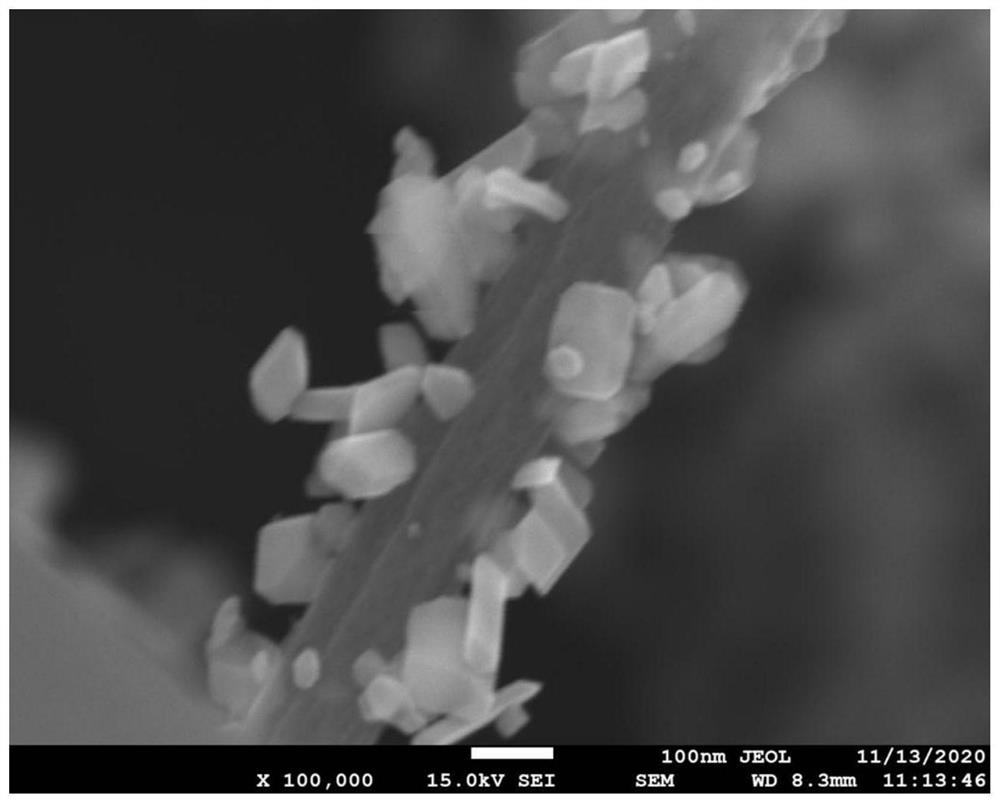

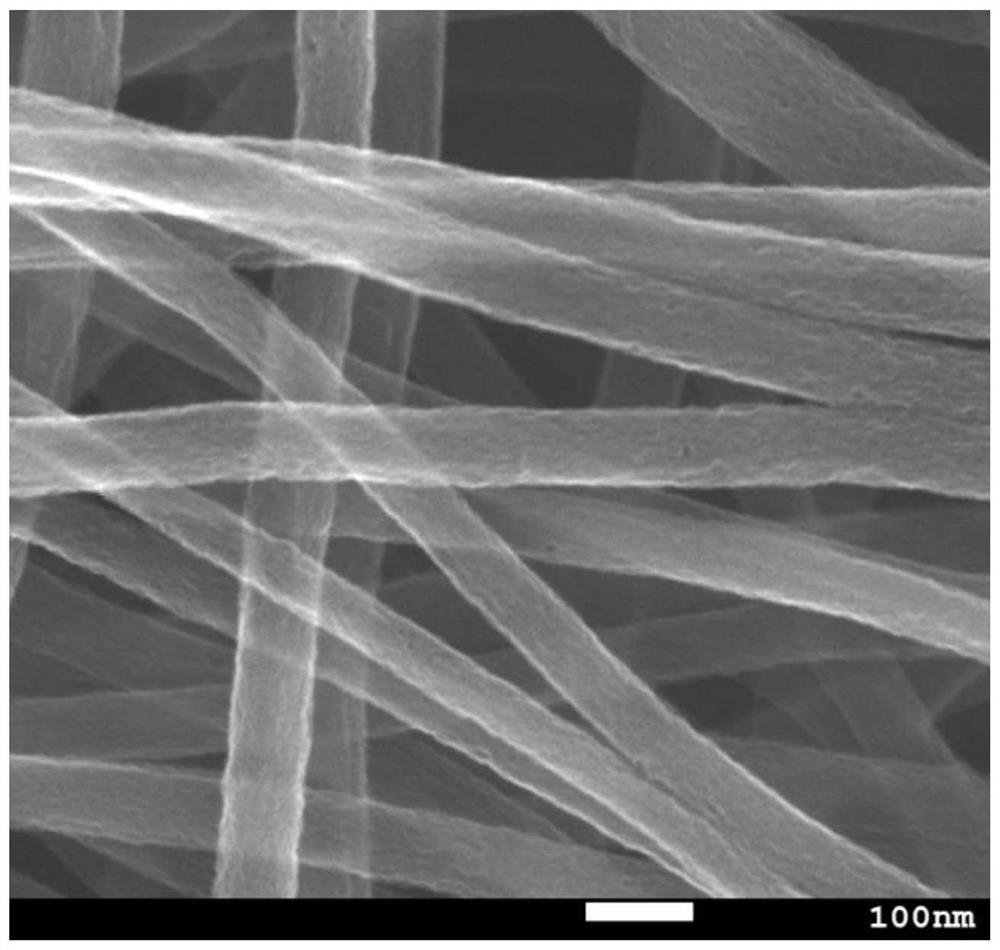

[0045] Step 1, preparation of nascent nanofibrous membrane: 1.0 g of polyacrylonitrile (PAN) and 0.3 g of polyvinylpyrrolidone (PVP) were sequentially added to 10 mL of N,N-dimethylformamide (DMF), and then heated at 60 °C Stir vigorously until PAN and PVP are completely dissolved to obtain a mixed solution. Then add 1.0 g of SnCl to the mixed solution 2 Stir at room temperature for 24 h to obtain a precursor solution. Electrospin the precursor solution with a roller device, specifically: transfer the precursor solution to a syringe with a stainless steel needle, connect the needle to a high-voltage power supply, push the material at a rate of 0.04ml / h, and apply 18 to the tip of the stainless steel needle. A constant voltage of kilovolts was used, and the distance between the stainless steel needle tip and the collector was fixed at 15 cm. The humidity of the electrospinning chamber was controlled at 75%, and the temperature was controlled at 25±5° C., and the nascent nanof...

Embodiment 2

[0058] Step 1, preparation of nascent nanofibrous membrane: 0.9 g of polyacrylonitrile (PAN) and 0.4 g of polyvinylpyrrolidone (PVP) were sequentially added to 11 mL of N,N-dimethylformamide (DMF), and then heated at 60 °C Stir vigorously until PAN and PVP are completely dissolved to obtain a mixed solution. Then add 0.9g SnCl to the mixed solution 2 Stir at room temperature for 24 h to obtain a precursor solution. Electrospin the precursor solution with a roller device, specifically: transfer the precursor solution to a syringe with a stainless steel needle, connect the needle to a high-voltage power supply, push the material at a rate of 0.045ml / h, and apply 21 to the tip of the stainless steel needle. A constant voltage of kilovolts was used, and the distance between the stainless steel needle tip and the collector was fixed at 17 cm. The humidity of the electrospinning chamber was controlled at 70%, and the temperature was controlled at 25±5° C., and the nascent nanofibe...

Embodiment 3

[0063] Step 1, preparation of nascent nanofibrous membrane: 0.8 g of polyacrylonitrile (PAN) and 0.2 g of polyvinylpyrrolidone (PVP) were sequentially added to 9 mL of N,N-dimethylformamide (DMF), and then heated at 60 °C Stir vigorously until PAN and PVP are completely dissolved to obtain a mixed solution. Then add 0.8g SnCl to the mixed solution 2 Stir at room temperature for 24 h to obtain a precursor solution. Electrospin the precursor solution with a roller device, specifically: transfer the precursor solution to a syringe with a stainless steel needle, connect the needle to a high-voltage power supply, push the material at a rate of 0.035ml / h, and apply 20 to the tip of the stainless steel needle. A constant voltage of kilovolts was used, and the distance between the stainless steel needle tip and the collector was fixed at 18 cm. The humidity of the electrospinning chamber was controlled at 65%, and the temperature was controlled at 25±5° C., and the nascent nanofiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com