Immobilized bio-enzyme microreactor based on starch-based nanomaterial and application thereof

A micro-reactor, nano-material technology, applied in the direction of immobilization on/in organic carriers, biological treatment devices, chemical instruments and methods, etc., can solve the problem of poor mechanical properties of natural starch hydrogels, limiting starch hydrogels Wide application, low stretchability and other problems, to achieve the effect of enhancing immobilization efficiency, improving stability and operating stability, and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Ultrasonically disperse 10 mg of graphene oxide (GO) in 10 mL of deionized water to obtain a GO suspension; stir and disperse 1 g of starch (Starch) in 10 mL of deionized water to obtain a starch suspension; add 2 mL of The GO suspension was mixed well so that the final concentration of GO in the mixed solution was 0.2 mg / mL, then the mixed solution was heated to 90 °C and stirred at a speed of 300 rpm for 3 h, and then ultrasonically treated in an ultrasonic bath at 60 °C for 2 h to obtain The homogeneous hydrogel was cooled to room temperature and freeze-dried to obtain a graphene oxide-modified starch hydrogel, denoted as GO@Starch.

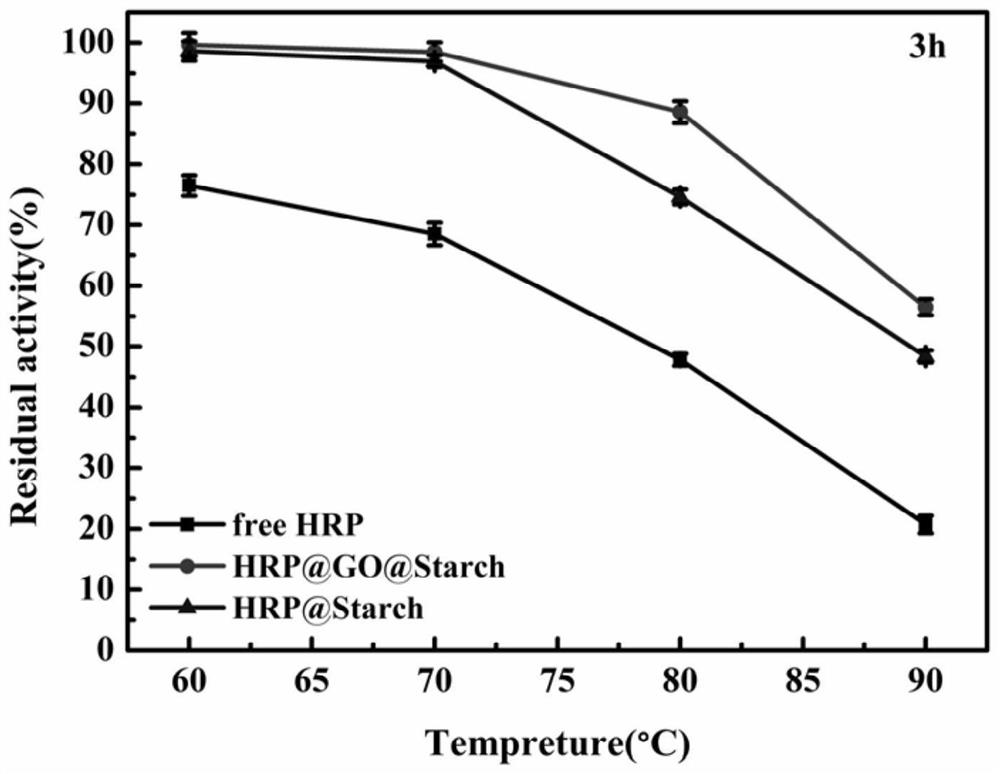

[0025] Weigh 5mg GO@Starch, add 1400μL PBS buffer solution with pH=5 and 100μL 0.25mmol·L - 1 HRP solution was shaken at a constant temperature of 29°C for 10 h, and after standing for 6 h, the supernatant was removed, and washed 2 to 3 times with PBS buffer to remove unfixed HRP, and a starch-based nanomaterial-based immobilized HRP m...

Embodiment 2

[0053] Application of the HRP@GO@Starch prepared in Example 1 to degrade bisphenol A in wastewater

[0054] Add 10 mg of HRP@GO@Starch (with HRP@Starch as a comparative test at the same time), artificial wastewater, and different concentrations of bisphenol A into a 10mL centrifuge tube, and finally add 36 μL of 0.1mol L -1 h 2 o 2 An aqueous solution was used to initiate the reaction, keeping the total solution volume at 3 mL. React at room temperature for 25 min under magnetic stirring, and extract 3 times with ethyl acetate after the reaction. Finally, all the extract was evaporated and removed with a rotary evaporator, and then the sample was dissolved with chromatographically pure acetonitrile to obtain a crude sample. The crude sample is filtered through a 0.22 μm organic phase filter membrane and used for high-performance liquid chromatography (HPLC-15C) analysis and determination. 乙腈 :V 水 =90:10) as the mobile phase, the flow rate is 0.5mL min -1 , the detection ...

Embodiment 3

[0058] Application of HRP@GO@Starch prepared in Example 1 to degrade 2,4-dichlorophenol in wastewater

[0059] A series of 2,4-dichlorophenol standard solutions with different concentrations were accurately prepared using methanol as a solvent, filtered through a 0.22 μm organic phase filter, and the peak areas corresponding to different substrate concentrations were determined by high performance liquid chromatography. Concentration and its corresponding peak area were plotted, and the standard curve equation was fitted. Add 10 mg of HRP@GO@Starch (while using HRP@Starch as a comparative test), artificial wastewater, and 2,4-dichlorophenol at different concentrations in a 10mL centrifuge tube, and finally add 36 μL of 0.1mol L - 1 h 2 o 2 An aqueous solution was used to initiate the reaction, keeping the total solution volume at 3 mL. After reacting for 20 minutes in the dark, centrifuge, take out 1000 μL of the reaction solution into the container with a pipette gun, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com