Impurity removal process and manufacturing process of semiconductor monocrystalline silicon wafer

A single crystal silicon wafer and semiconductor technology, applied in semiconductor/solid-state device manufacturing, crystal growth, electrical components, etc., can solve problems such as inability to maintain stability, reduce surface metal pollution levels, exceed specifications, and improve the quality of silicon wafers , the effect of reducing the level of bulk metal contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

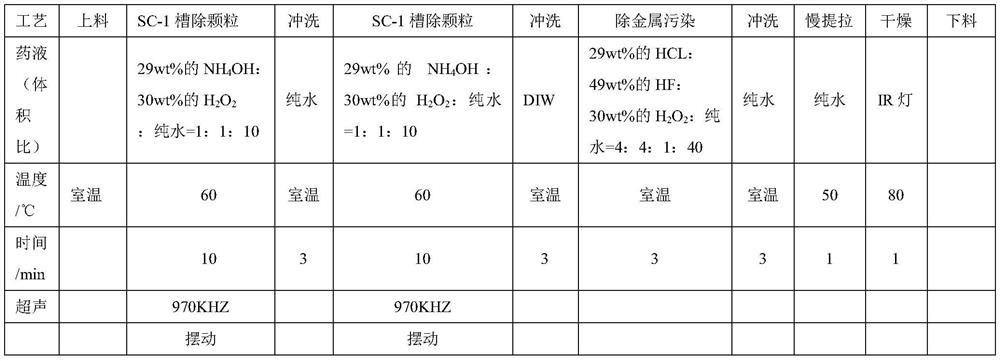

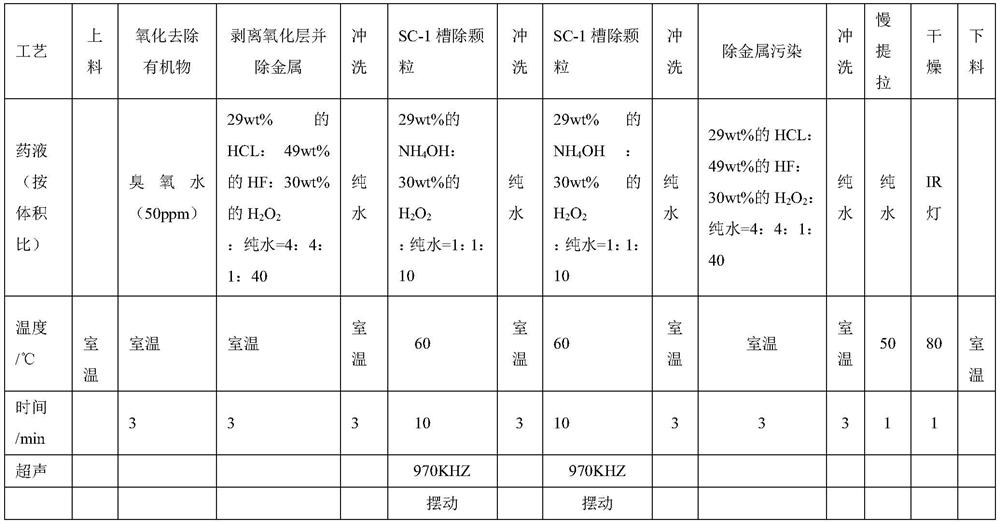

Method used

Image

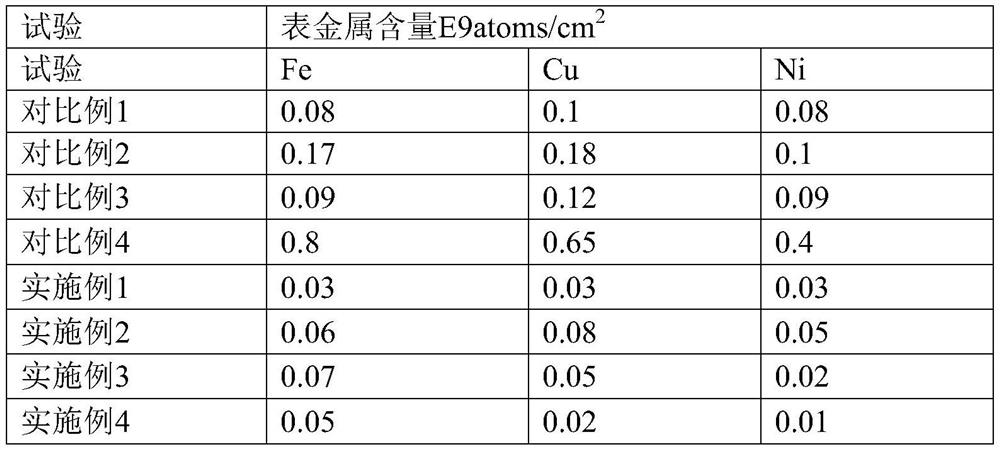

Examples

Embodiment 1

[0072] Heat treatment step a) Place the silicon wafer in a rapid annealing furnace at a heating rate of 150°C / s, raise the temperature to 1250°C, hold for 3s, then cool down to 900°C at a cooling rate of 150°C / s, and remove from the rapid annealing furnace Take out the silicon wafer and cool it naturally for later use, and the atmosphere in the furnace chamber is ammonia gas; step b) put the silicon wafer into a heat treatment furnace from 600°C to 900°C at a rate of 1°C / min and keep it warm for 16 hours, the atmosphere is 5% oxygen 95% nitrogen . The thickness of the surface layer of oxygen-containing precipitates on silicon wafers after heat treatment is about 9 microns, and the density is about 1E9 / cm 2 , polished to remove the surface thickness of about 10 microns.

Embodiment 2

[0074] Heat treatment step a) Place the silicon wafer in a rapid annealing furnace at a heating rate of 200°C / s, raise the temperature to 1350°C, hold for 2s, and then cool down to 800°C at a cooling rate of 200°C / s, then remove from the rapid annealing furnace Take out the silicon wafer and cool it naturally for later use, the atmosphere in the furnace chamber is argon; step b) put the silicon wafer into the heat treatment furnace from 700 ° C to 1000 ° C at a rate of 0.5 ° C / min and keep it for 4 hours, the atmosphere is 5% oxygen 95% nitrogen . The thickness of the surface layer of oxygen-containing precipitates on silicon wafers after heat treatment is about 5 microns, and the density is about 9E9 / cm 2 , polished to remove the surface thickness of about 6 microns.

Embodiment 3

[0076] Heat treatment step a) Place the silicon wafer in a rapid annealing furnace at a heating rate of 100°C / s, raise the temperature to 1300°C, hold for 1s, and then cool down to 950°C at a cooling rate of 100°C / s, then remove from the rapid annealing furnace Take out the silicon wafer and cool it naturally for later use, the furnace chamber atmosphere is nitrogen; step b) put the silicon wafer into a heat treatment furnace from 800 ° C to 1100 ° C at a rate of 2 ° C / min and keep it for 10 hours, the atmosphere is 5% oxygen 95% nitrogen. The thickness of the surface layer of oxygen-containing precipitates on silicon wafers after heat treatment is about 18 microns, and the density is about 5E9 / cm 2 , polished to remove the surface thickness of about 20 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com