Ammonia borane/silicon sphere/mesoporous silica nano-composite particle, and preparation and application thereof

A technology of nanocomposite particles and mesoporous silica, applied in the direction of silica, silicon oxide, boron compound active ingredients, etc., can solve the problem of inability to remove CTAC well, lengthy synthesis process of composite particles, and influence on the formation of mesoporous structure To achieve the effect of shortening the preparation cycle, flexible and adjustable pore size distribution, and promoting nerve regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

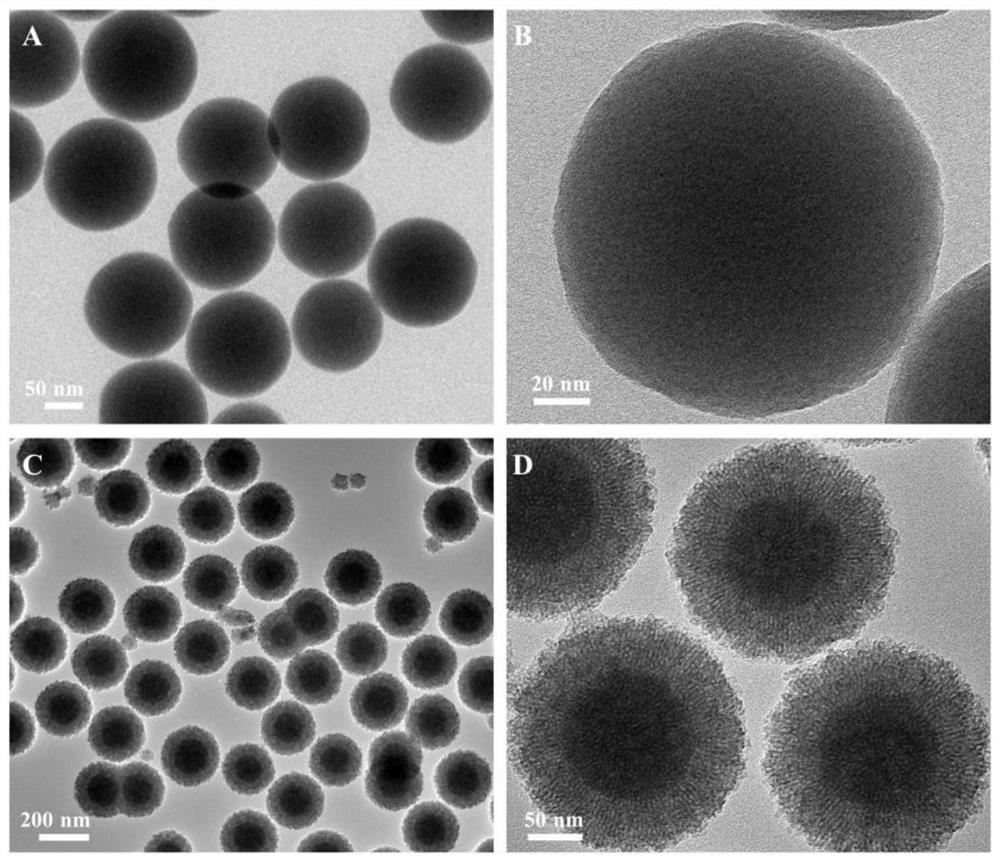

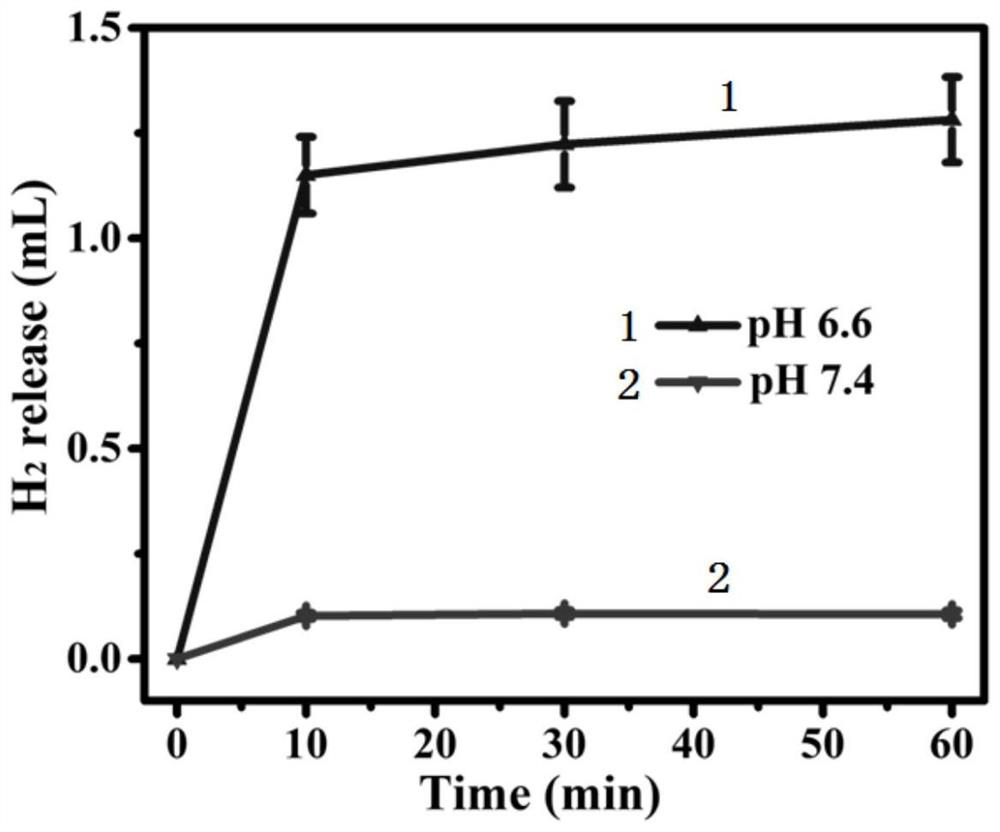

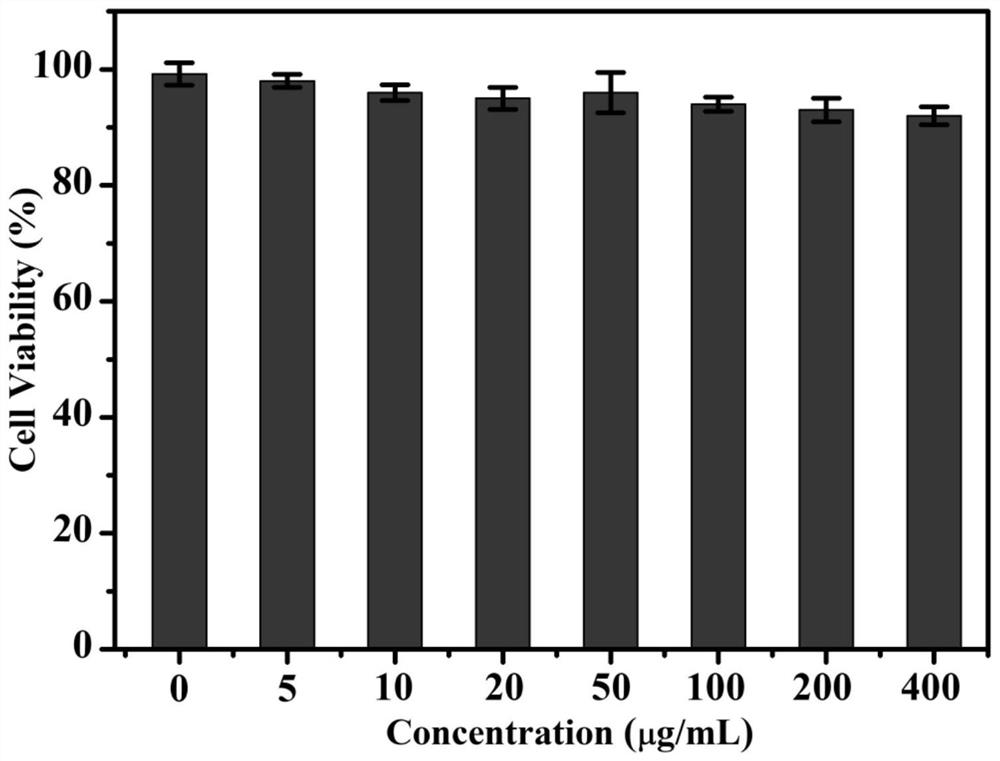

[0048] In this embodiment, ammonia borane / silica sphere / mesoporous silica nanocomposite particles (AB / SiO2 @mSiO 2 ), the composite structure nanoparticles are based on solid silicon spheres as the core and silicon oxide as the outer shell, and the template agent is removed by methanol to obtain mesoporous SiO 2 @mSiO 2 , and then loaded ammonia borane small molecule prodrug.

[0049] (1) The preparation method of this ammonia borane / silicon sphere / mesoporous silica nanocomposite particle comprises the following steps:

[0050] (1-1) Silicon dioxide dSiO 2 Preparation of nanoparticles: In a 100mL single-necked bottle, according to the measurement of the reaction process of tetraethyl orthosilicate and water, add 74mL of ethanol, 15mL of water and 3.2mL of ammonia water, stir at 30°C for 20min, then drop in 2.8mL Tetraethyl orthosilicate was hydrolyzed and polymerized, stirred in a water bath at 30°C for 2 hours, washed twice with centrifuged alcohol, washed once with water,...

Embodiment 2

[0068] The preparation method of ammonia borane / silicon sphere / mesoporous silica nanocomposite particle of the present embodiment is basically the same as that of embodiment 1, the difference is:

[0069] In step (1-1), the amount of tetraethyl orthosilicate added is 2.5 mL.

[0070] In step (1-2), the addition of triethanolamine (TEA) is 0.2g, and the monodisperse SiO dispersed in deionized water 2 The amount of nanoparticles added was 8 mL.

[0071] In step (1-3), the amount of methanol solution of 1% NaCl added is 40 mL.

[0072] In step (1-4), the addition of ammonia borane is 200mg, SiO 2 @mSiO 2 Composite nanoparticles are 1.5 mL.

[0073] The detection results and properties of the ammonia borane / silicon sphere / mesoporous silica nanocomposite particles obtained in Example 2 are basically the same as those in Example 1.

Embodiment 3

[0075] The preparation method of ammonia borane / silicon sphere / mesoporous silica nanocomposite particle of the present embodiment is basically the same as that of embodiment 1, the difference is:

[0076] In step (1-1), the addition of tetraethyl orthosilicate is 4.5 mL.

[0077] In step (1-2), the addition of cetyltrimethylammonium chloride is 1.5g, and the monodisperse SiO dispersed in deionized water 2 The amount of nanoparticles added was 15 mL.

[0078] In step (1-3), the amount of methanol solution of 1% NaCl added is 65 mL.

[0079] In step (1-4), the addition of ammonia borane is 300mg, SiO 2 @mSiO 2 Composite nanoparticles are 2.5 mL.

[0080] The detection results and properties of the ammonia borane / silicon sphere / mesoporous silica nanocomposite particles obtained in Example 3 are basically the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com