Efficient denitration agent for waste gas treatment and preparation method thereof

A waste gas treatment and denitration agent technology, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of affecting the adsorption efficiency, the decrease of the adsorption efficiency, and the unfavorable popularization and application, so as to reduce the production cost and simplify the processing process , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

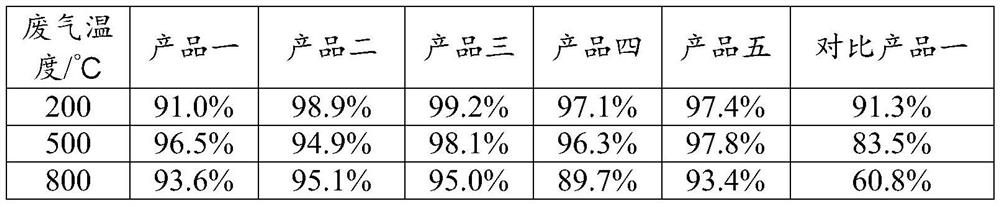

Examples

Embodiment 1

[0019] A method for preparing a high-efficiency denitration agent for waste gas treatment, comprising the following steps:

[0020] (1) Add butyl titanate to 45 parts of graphene oxide, mix uniformly; The consumption ratio of graphene oxide and liquid precursor is 1g:10mL;

[0021] (2) Add 15 parts of limestone powder, 12 parts of nano-scale calcium oxide, 6 parts of nano-scale magnesium oxide, 5 parts of titanium dioxide, 2 parts of sodium carbonate in the mixture of step (1); after mixing evenly, dip for 48h, after dipping finishes, reduce pressure distillation until the liquid content is below 8%, and then sintered at 350°C for 5 hours to obtain the denitration agent carrier;

[0022] (3) Then add ammonium chloride and ammonia water with a mass fraction of 18wt%. The ratio of ammonium chloride to ammonia water is 1g:6mL. After mixing evenly, soak for 6 hours. After the completion of the granulation, a high-efficiency denitrification agent for waste gas treatment is obtaine...

Embodiment 2

[0024] A method for preparing a high-efficiency denitration agent for waste gas treatment, comprising the following steps:

[0025] (1) Add alkanolamide to 50 parts of graphene oxide, mix uniformly; The consumption ratio of graphene oxide and liquid precursor is 1g:15mL;

[0026] (2) Add 20 parts of limestone powder, 18 parts of nano-scale calcium oxide, 8 parts of nano-scale magnesium oxide, 1 part of titanium dioxide, 5 parts of sodium carbonate in the mixture of step (1); dipping 48h after mixing evenly, reduce after dipping finishes pressure distillation until the liquid content is below 8%, and then sintered at 350°C for 5 hours to obtain the denitration agent carrier;

[0027] (3) Then add urea and ammonia water with a mass fraction of 5wt%, the dosage ratio of urea and ammonia water is 1g:10mL, mix evenly and impregnate for 6 hours, dry at 120°C to constant weight after impregnation, and granulate after loading , to obtain a high-efficiency denitrification agent for wa...

Embodiment 3

[0029] A method for preparing a high-efficiency denitration agent for waste gas treatment, comprising the following steps:

[0030] (1) Add butyl titanate to 45 parts of graphene oxide, mix uniformly; The consumption ratio of graphene oxide and liquid precursor is 1g:15mL;

[0031] (2) Add 15 parts of limestone powder, 12 parts of nano-scale calcium oxide, 8 parts of nano-scale magnesium oxide, 5 parts of titanium dioxide, 2 parts of sodium carbonate in the mixture of step (1); after mixing evenly, dip for 72h, after dipping finishes, reduce pressure distillation until the liquid content is below 5%, and then sintered at 500°C for 8 hours to obtain the denitration agent carrier;

[0032] (3) Then add ammonium chloride and ammonia water with a mass fraction of 18wt%, the ratio of ammonium chloride to ammonia water is 1g:6mL, mix evenly and soak for 10h, dry to constant weight at 120°C after immersion, load After the completion of the granulation, a high-efficiency denitrificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com