Special oil-soluble flocculating agent for oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid, oil-soluble technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high post-processing cost, high energy consumption, strict equipment requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

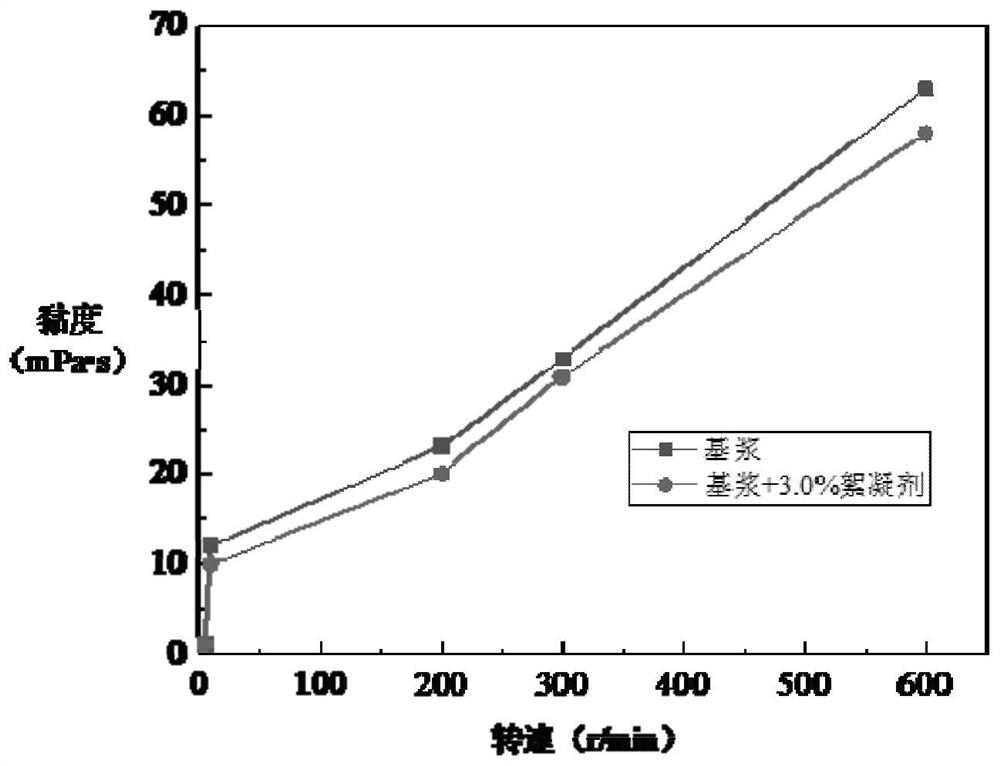

Examples

preparation example Construction

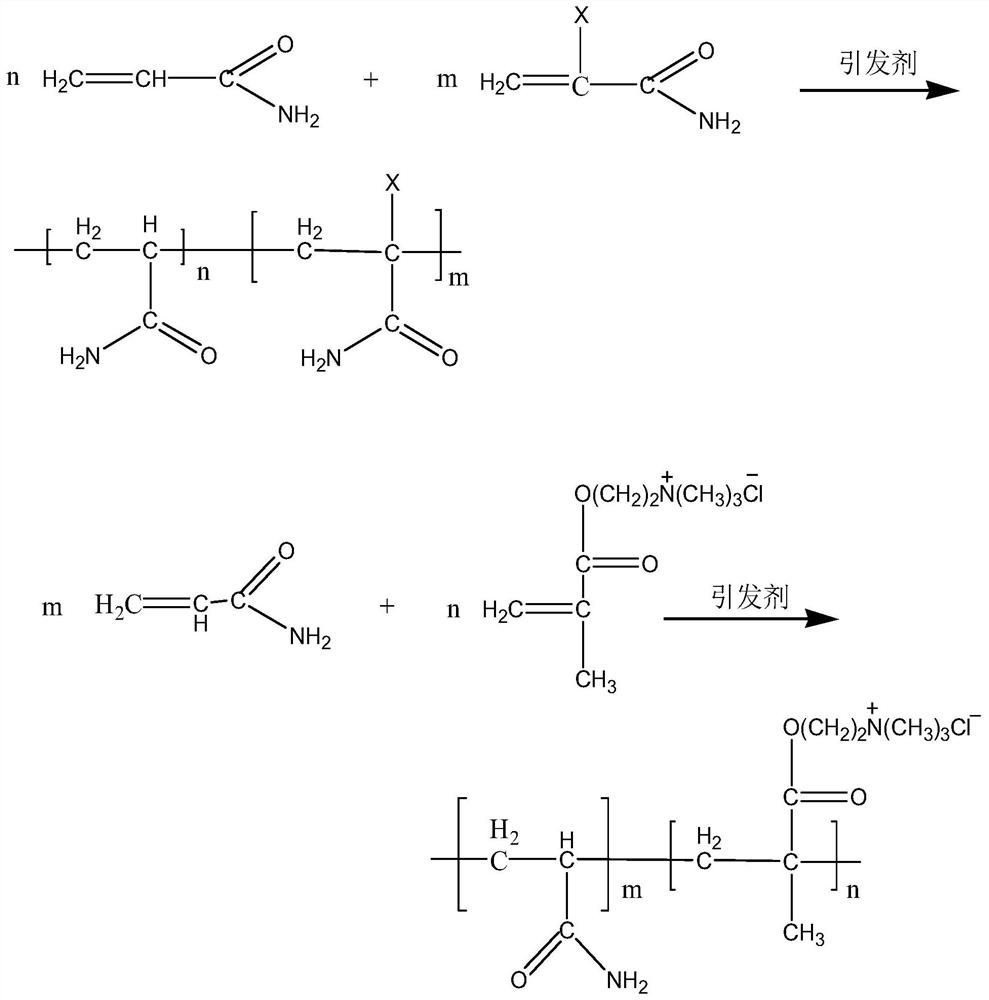

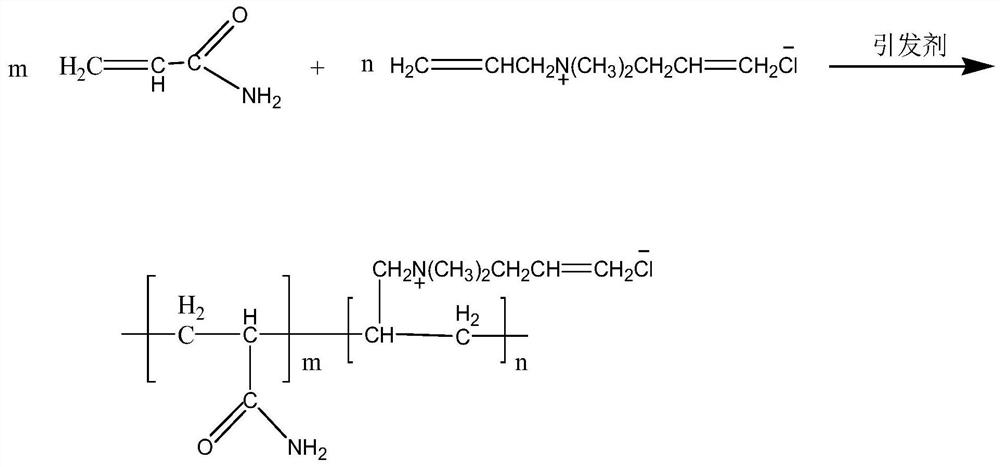

[0051] The present invention also provides a method for preparing an oil-soluble flocculant for oil-based drilling fluid, which is used to prepare the above-mentioned oil-soluble flocculant for oil-based drilling fluid, comprising the following steps:

[0052] Step 1, according to the mass parts of 20-50 parts of base oil, 20-45 parts of water, 15-30 parts of monomer, 5-10 parts of grafted monomer, 10-30 parts of emulsifier, and 0.1-0.3 parts of initiator Weigh each raw material. Wherein, the monomer is acrylamide or its derivatives; the graft monomer is methacryloyl ethyl trimethyl ammonium chloride (DMC) or dimethyl diallyl ammonium chloride (DMDAAC) One of.

[0053] Step 2, mixing the base oil with the oil-soluble emulsifier in the emulsifier to obtain an oil phase; when there is a water-soluble emulsifier in the emulsifier, the monomer, the grafted monomer The water-soluble emulsifier in the body and the emulsifier is fully dissolved in part of the water, thereby obtaini...

Embodiment 1

[0070] A special oil-soluble flocculant for oil-based drilling fluid, the preparation method of which comprises the following steps:

[0071] Step A1. Weigh 70 g of white oil, 60 g of tap water, 10 g of deionized water, 40 g of acrylamide, 15 g of DMC, 8015 g of Span, 7 g of sodium lauryl sulfate, and 0.5 g of ammonium persulfate-sodium bisulfite.

[0072] Step A2, put white oil and Span 80 in the same mixing cup and stir to obtain the oil phase; fully dissolve acrylamide, grafted monomer DMC and sodium lauryl sulfate in part of the water to obtain the water phase ; Ammonium persulfate-sodium bisulfite is dissolved in the remaining water to obtain an initiator solution.

[0073] Step A3, drop the water phase into the oil phase drop by drop, stir at a high speed for 0.5 h, and the rotation speed of the high speed stirring is 8000 r / min, so as to obtain a pre-emulsion.

[0074] Step A4, put the pre-emulsion in a four-necked flask, and pass nitrogen gas, heat the four-necked fla...

Embodiment 2

[0076] A special oil-soluble flocculant for oil-based drilling fluid, the preparation method of which comprises the following steps:

[0077] Step B1. Weigh 80g of diesel oil, 55g of tap water, 10g of deionized water, 40g of acrylamide, 15g of DMDAAC, 8015g of Span, 3g of cetyltrimethylammonium chloride, and 0.25g of tetramethylethylenediamine-sodium sulfite.

[0078] Step B2, put diesel oil and Span 80 in the same stirring cup and stir and mix to obtain an oil phase; fully dissolve acrylamide, graft monomer DMDAAC and cetyltrimethylammonium chloride in part of the water, thereby An aqueous phase is obtained; tetramethylethylenediamine-sodium sulfite is dissolved in the remaining water to obtain an initiator solution.

[0079] Step B3, drop the water phase into the oil phase drop by drop, and stir for 1 hour at a high speed of 7000 r / min to obtain a pre-emulsion.

[0080] Step B4, put the pre-emulsion in a four-necked flask, and pass nitrogen gas, heat the four-necked flask t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com