Synthetic method of L-galactose

A synthesis method, galactose technology, applied in biochemical equipment and methods, immobilized on/in organic carriers, enzymes, etc., can solve the problems of high price, low overall yield, long preparation route, etc. The effect of cheap raw materials, simple reaction conditions and short preparation route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

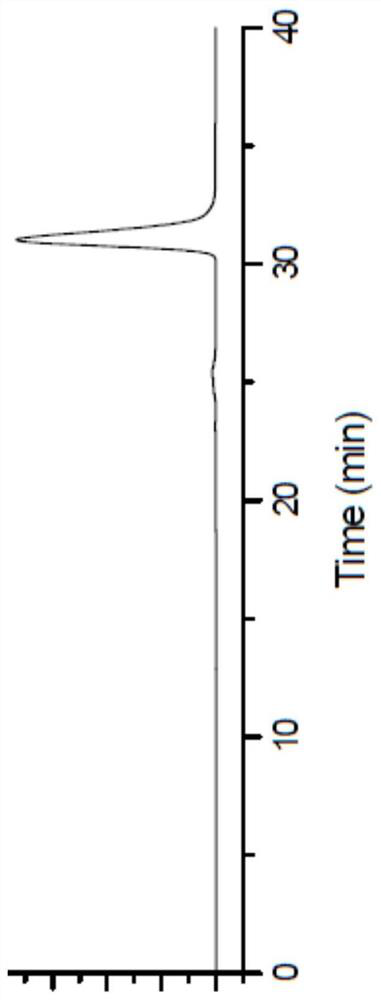

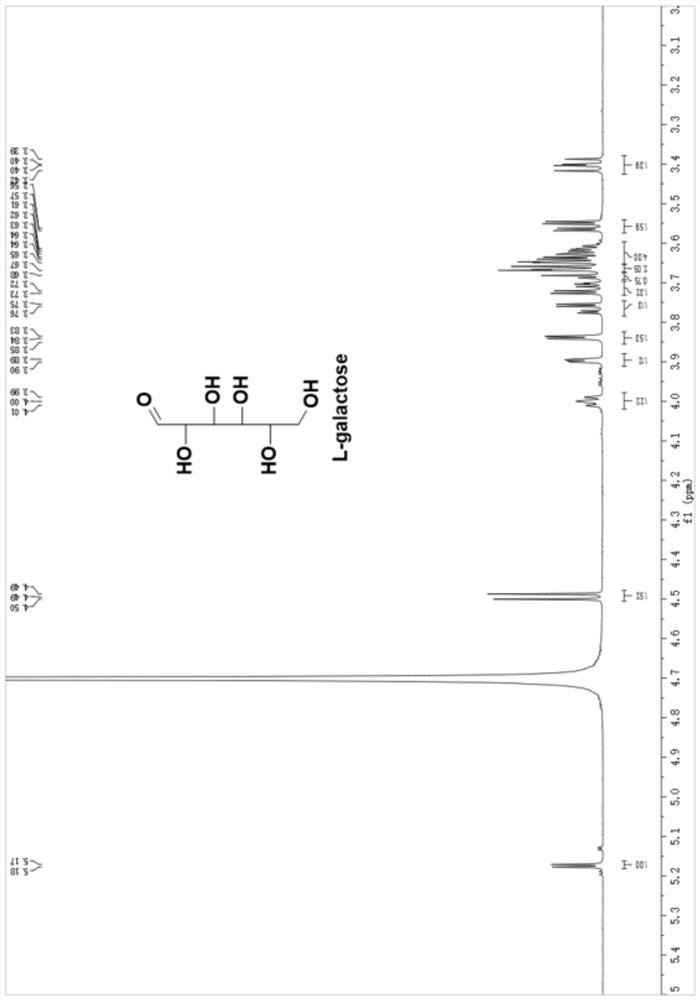

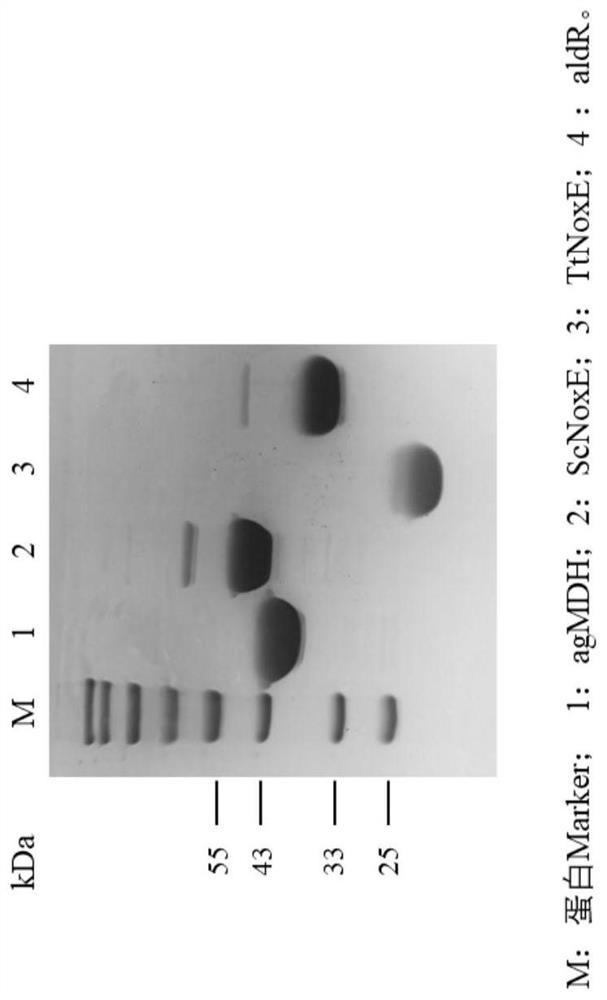

[0035] Example 1: Using galactitol as a raw material, liquid enzymes (agMDH, ScNoxE) prepare L-galactose

[0036]

[0037] Add 27.3 grams of galactitol (150 mM) and 1.42 grams of oxidized nicotinamide adenine dinucleotide disodium salt (NAD + ,2mM), then adjust the pH value of the solution to 8.0, add crude enzyme solution (1500U agMDH, 3000U ScNoxE), and then transfer the reaction solution into a pressure-resistant reactor to maintain an oxygen pressure of 1.5 atmospheres at 30°C and slowly stir the reaction 6 Hour. After the reaction, add HCl aqueous solution to adjust the pH to 1.0 to denature, precipitate the protein and remove it by high-speed centrifugation, then adjust the pH of the solution to pH 7.0, use D201 anion exchange resin (Tianjin Yunkai Resin Technology Co., Ltd.) to remove impurities, and finally use reverse osmosis After membrane desalination, concentration and crystallization (ethanol:water, 3:1, v:v) yielded 22 g of L-galactose (colorless granular sol...

Embodiment 2

[0041] Example 2: Using galactitol as a raw material, immobilized enzymes (agMDH, ScNoxE) to prepare L-galactose

[0042] Similar to Example 1, but mixed immobilized agMDH and ScNoxE enzymes are used for catalysis instead of liquid enzymes, and the immobilized enzymes can be recycled after the reaction.

[0043] Add 18.2 grams of galactitol (100 mM) and 1.42 grams of oxidized nicotinamide adenine dinucleotide disodium salt (NAD + , 2mM), then adjust the pH value of the solution to 8.0, add immobilized mixed enzyme (5000U, agMDH, ScNoxE activity unit ratio 1:5), and then transfer the reaction solution into a pressure-resistant reactor to maintain an oxygen pressure of 2 atmospheres Slowly shake the reaction at 30°C for 12 hours. After the reaction was completed, the immobilized enzyme was recovered by filtration (the immobilized enzyme was washed three times with 50mM pH 8.0 Tris buffer and stored at 4°C for later use). Concentrate and crystallize (ethanol:water, 3:1, v:v) af...

Embodiment 3

[0045] Example 3: Using galactitol as a raw material, liquid enzymes (agMDH, TtNoxE, Catalase) prepare L-galactose

[0046]

[0047] Add 18.2 grams of galactitol (100 mM) and 1.42 grams of oxidized nicotinamide adenine dinucleotide disodium salt (NAD + ,2mM), then adjust the pH value of the solution to 7.5, add crude enzyme solution (1000U agMDH, 3000U TtNoxE, 1000U catalase), and then transfer the reaction solution into a pressure-resistant reactor to maintain an oxygen pressure of 2 atmospheres at 30°C and slowly The reaction was stirred for 8 hours. After the reaction, add HCl aqueous solution to adjust the pH to 1.0 to denature, precipitate the protein and remove it by high-speed centrifugation, then adjust the pH of the solution to pH 7.0, use D201 anion exchange resin (Tianjin Yunkai Resin Technology Co., Ltd.) to remove impurities, and finally use reverse osmosis After membrane desalination, concentration and crystallization (ethanol:water, 3:1, v:v) yielded 12.8 g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com