Photoelectric catalytic reactor

A photoelectric catalysis and reactor technology, which is applied in chemical instruments and methods, water treatment of special compounds, light water/sewage treatment, etc., can solve the problems of low photocatalytic efficiency and high operating cost, and achieve photocatalytic efficiency improvement, photocatalytic Performance improvement, effect of improving photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

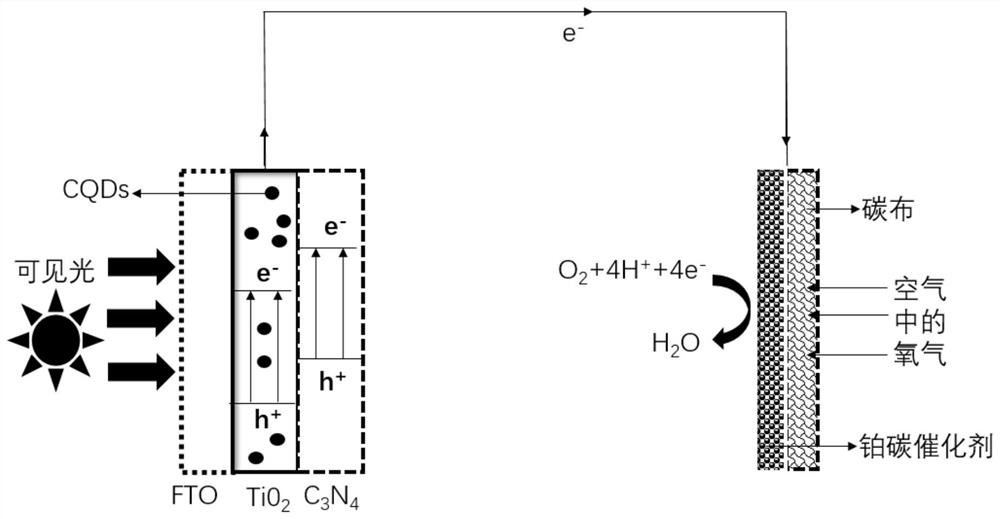

[0062] TiO in this example 2 / C 3 N 4 / CQDs photoelectrode preparation method is as follows:

[0063] (1) TiO 2 / C 3 N 4 Electrode preparation: conductive glass FTO (7Ω / m 2 , diameter 34mm, thickness 2.2mm) with isopropanol: ultrapure water: acetone (volume ratio 1:1:1) for ultrasonic cleaning for 1h. Mix 40mL 36.5wt% concentrated hydrochloric acid with 40mL ultrapure water, then add 1.32mL tetrabutyl titanate and mix well, put the mixed solution and the conductive glass FTO after ultrasonic cleaning into the hydrothermal reaction kettle, the FTO conductive glass faces Above, take out the conductive glass after reacting at 150°C for 5 hours, rinse it and dry it naturally, put it into a 30mL ceramic crucible together with 2g of dicyandiamide, wherein the dipolycyanamide is at the bottom, the conductive glass is at the top, and the conductive face down. Then put it into a muffle furnace and heat it at 550°C for 3h to make TiO 2 / C 3 N 4 electrode.

[0064] (2) Dissol...

Embodiment 2

[0075] The preparation method of the air diffusion cathode of the present embodiment is as follows:

[0076] (1) Apply PDFE (polytetrafluoroethylene) on one side of the carbon cloth (4cm×8cm) with conductive carbon black to form a waterproof surface. The amount of PDFE applied is about 1mL. After drying, put it into the muffle furnace at 350°C , 10min, repeat 2 times to get waterproof carbon cloth;

[0077] (2) Add 0.09 g graphite into a 10 mL plastic centrifuge tube, then measure 100 μL deionized water, 800 μL 5wt% perfluorosulfonic acid solution, 400 μL isopropanol, and add 12 glass beads. Vortex for 5 min to mix well. The mixture is quickly applied to the other side of the waterproof carbon cloth (opposite to the waterproof surface), and left to dry for 24 hours to obtain an air diffusion cathode.

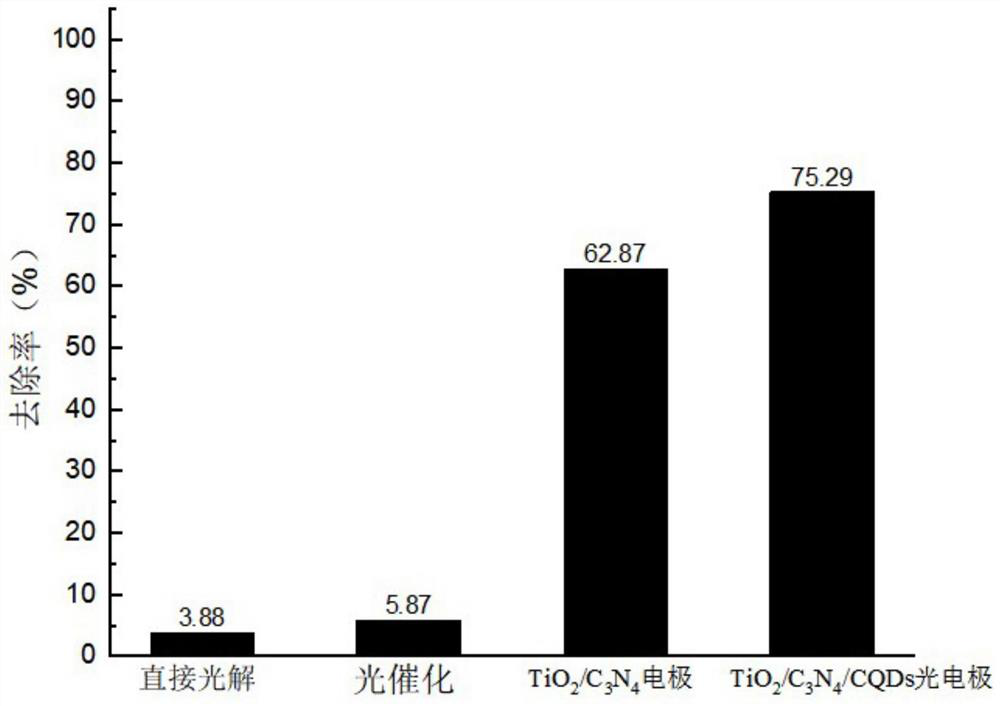

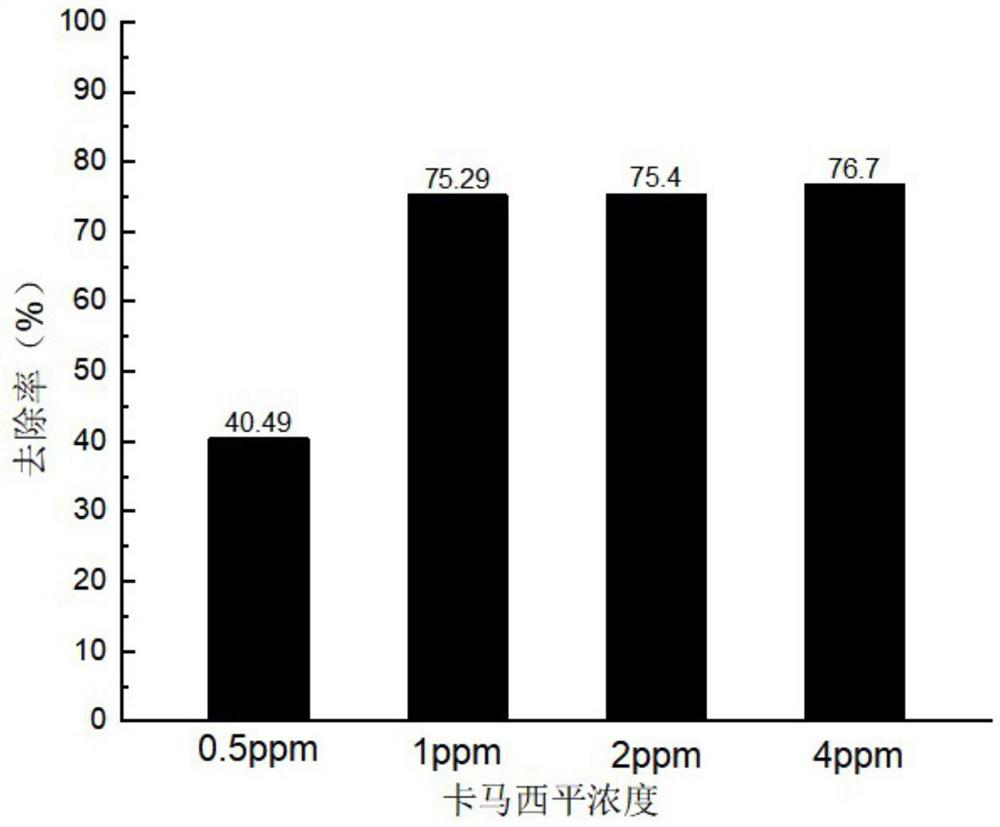

[0078] The TiO that embodiment 1 makes 2 / C 3 N 4 The / CQDs photoelectrode and the air diffusion cathode prepared in this example are connected to both sides of the plexigl...

Embodiment 3

[0082] The preparation method of the Fenton-like air diffusion cathode of the present embodiment is as follows:

[0083] (1) Apply PDFE (polytetrafluoroethylene) on one side of the carbon cloth (4cm×8cm) with conductive carbon black to form a waterproof surface. The amount of PDFE applied is about 1mL. After drying, put it into the muffle furnace at 350°C , 10min, repeat 2 times to get waterproof carbon cloth;

[0084] (2) Weigh 0.18g iron-manganese-copper ternary catalyst, the mass ratio of iron-manganese-copper is 3:1:8, add 0.09g graphite into a 10mL plastic centrifuge tube, then measure 100μL deionized water, 800μL 5wt% perfluorosulfur acid solution, 400 μL isopropanol, and add 12 glass beads. Vortex for 5 min to mix well. The mixture is quickly applied to the other side of the waterproof carbon cloth (opposite to the waterproof surface), and left to dry for 24 hours to obtain a Fenton-like air diffusion cathode.

[0085] The TiO that embodiment 1 makes 2 / C 3 N 4 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com