Large-scale preparation method of protamine peptide

A protamine and nucleoprotein technology, applied in the field of large-scale preparation of protamine peptides, can solve the problems of complicated and time-consuming purification steps, high cost, inability to realize industrialized amplification and large-scale production, etc., and achieves good flavor and time consumption. Less and more productive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

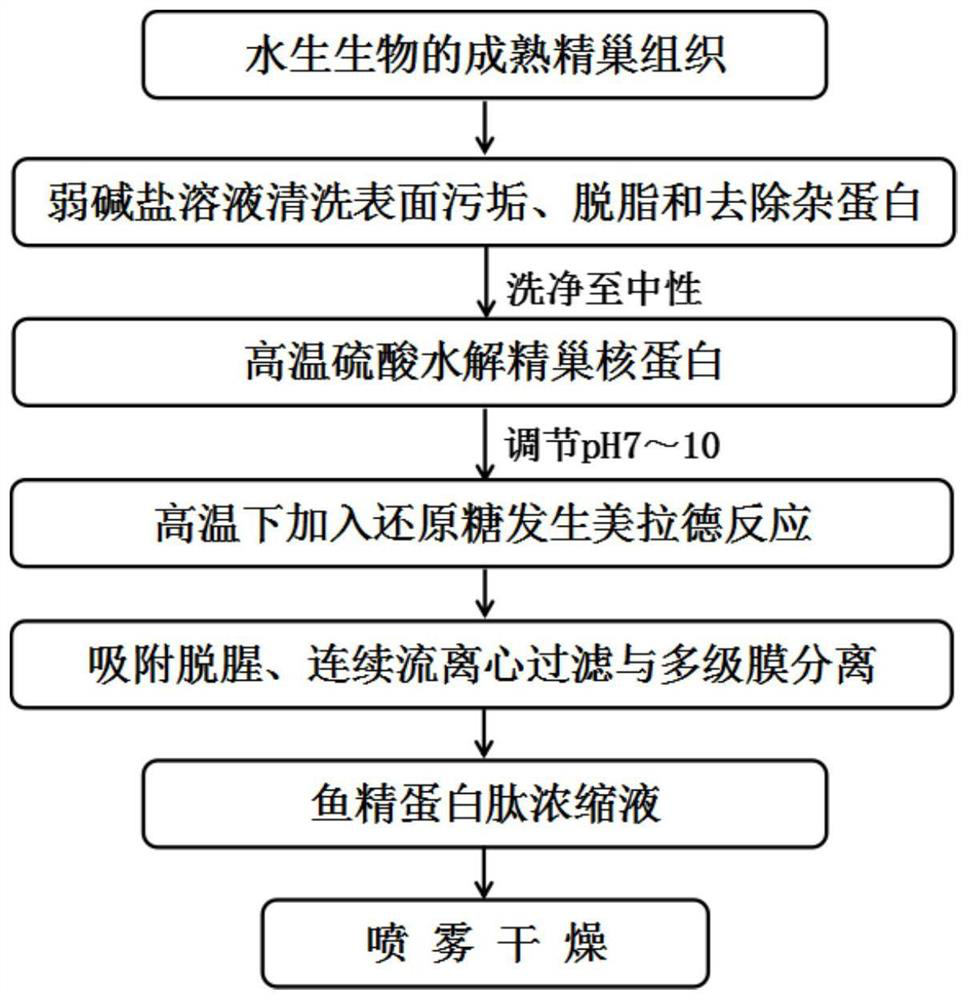

[0048] A method of preparation of a fish essence peptide, steps are as follows:

[0049] (1) Raw material pretreatment

[0050] In the reactor in the reactor, the sodium bicarbonate is added 4 times the sodium hydrogencarbonate mixture with sodium chloride, stirred for 2 hours, washed with water, where the mass concentration of sodium bicarbonate is 3%, salt solution The mass volume concentration is 5%;

[0051] (2) High temperature sulfuric acid hydrolyzed nest nuclear protein

[0052] The nest of the pretreated and washed, was placed in the reaction kettle, adding deionized water having a weight nest weight, adding concentrated sulfuric acid to adjusting pH of 2, and the reaction temperature is 95 ° C, stirred for 4 hours;

[0053] (3) Merad reaction

[0054] Under high temperature conditions, the calcium hydroxide regulation pH is 6, and then the sodium hydroxide is added to 7.5; adding a glucose with a sodium flexible nest weight, the reaction temperature is 85 ° C, stirred fo...

Embodiment 2

[0062] A method of preparation of a fish essence peptide, steps are as follows:

[0063] (1) Raw material pretreatment

[0064] In the reactor, the squid is added to the reaction kettle, and the weight of the squid is 2 times the weight of sodium hydrogen carbonate and the sodium chloride mixture, stirred for 3 hours, washed with water, where the mass concentration of the potassium carbonate solution is 4%, salt solution The mass volume concentration is 4%;

[0065] (2) High temperature sulfuric acid hydrolyzed nest nuclear protein

[0066] The essence of the pretreated and washed in the reactor is placed in the reaction kettle, and a deionized water having a weight nest weight is added, and the concentrated sulfuric acid regulates the pH of 2.5, and the reaction temperature is 100 ° C, stirred for 3 hours;

[0067] (3) Merad reaction

[0068] Under high temperature conditions, the calcium hydroxide regulation pH was added to 5.5, and then the potassium hydroxide was adjusted pH o...

Embodiment 3

[0076] A method of preparation of a fish essence peptide, steps are as follows:

[0077] (1) Raw material pretreatment

[0078] In the reactor in the reactor, the squid was added to the reaction kettle, and the weight of the squid was added to the sodium bicarbonate mixture with the potassium chloride, stirred for 1 hour, washed with water, where the mass concentration of sodium bicarbonate solution was 2%, the quality of the salt solution The volume concentration is 3%;

[0079] (2) High temperature sulfuric acid hydrolyzed nest nuclear protein

[0080] The nest of the squid passes through the pretreated and washed, and a deionized water of 0.5 times the weight of the fine nest is added, and the concentrated sulfuric acid is adjusted to be 3, and the reaction temperature is 90 ° C, stirred for 4 hours;

[0081] (3) Merad reaction

[0082] Under high temperature conditions, the calcium hydroxide regulation pH was added to 6.5, and then the sodium hydroxide was adjusted to be 8.5; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com