Zinc oxide nanorod ternary composite material as well as preparation method and application thereof

A technology of zinc oxide nanorods and composite materials, which is applied in the field of zinc oxide nanorod ternary composite materials and its preparation, can solve the problems of limited wastewater treatment effect, achieve good photocatalytic effect, good photoresponse effect, and multiple active sites point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 graphene oxide (hereinafter referred to as RGO) preparation

[0033] RGO was synthesized by a modified Hummer method. The method is to mix 360ml of concentrated H 2 SO 4 and 40ml concentrated H 3 PO 4 With proper mixing, 3 g of graphite powder was slowly added to the solution and stirring was continued for 3 h. Subsequently, 18 g of potassium permanganate was appropriately ground and slowly added to the solution, and the solution was continuously stirred for 12 h under the condition of a magnetic stirrer at 50° C. During this reaction, the solution color changed to dark purple, green, and then dark brown. Pour the dark brown solution into a beaker with a capacity of 400ml and keep it with a popsicle, add 3ml of H to the solution 2 o 2 And stir for 2h. The residual particles were then washed three times with HCl and several times with ethanol and distilled water. Finally, the particles were dried in a hot air oven at 60 °C for 48 h to obtain RGO.

...

Embodiment 2

[0035] Embodiment 2 biochar preparation

[0036] The white spongy part of pomelo peel was separated, and the remaining pomelo peel was dried at 80°C for 72 hours, ground into powder and passed through a 100-mesh sieve. Afterwards, the powder was carbonized in a quartz tube furnace at 400 °C under a nitrogen atmosphere. The carbonized product was immersed in KOH solution in a nickel crucible for 1 h, then activated at 400 °C for 2 h, and slowly pyrolyzed at 800 °C for 2 h. After cooling to room temperature, the final product was thoroughly washed with 0.1 mol / L HCl and deionized water, and finally dried at 80°C for 24 hours, and ground to obtain biochar powder for future use.

Embodiment 3

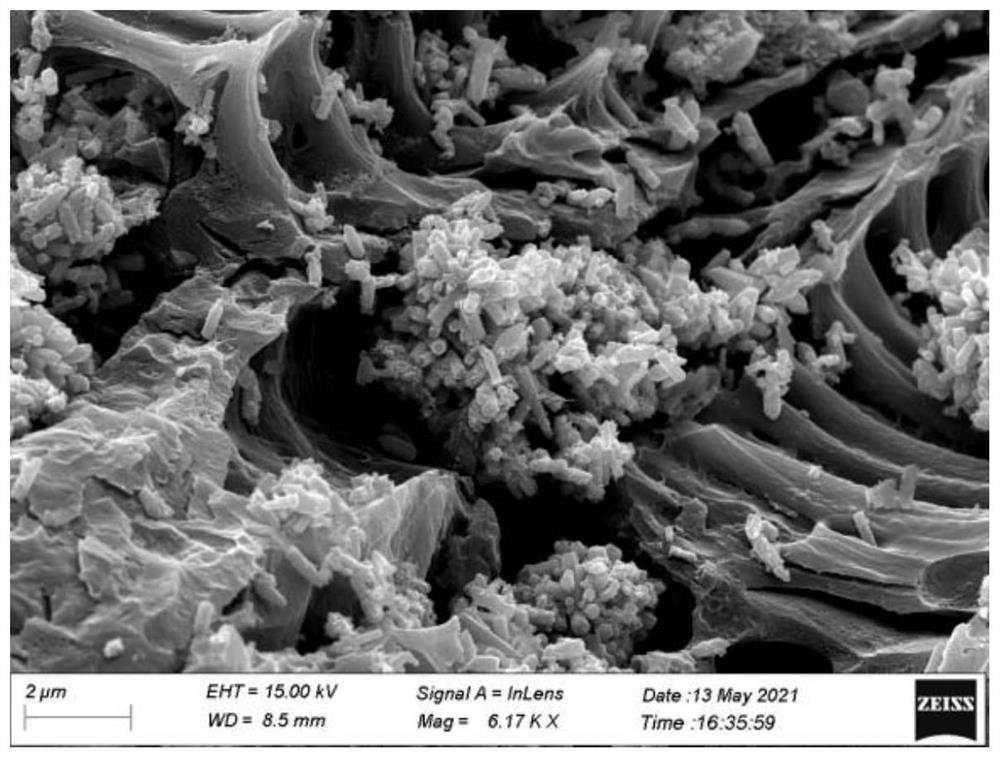

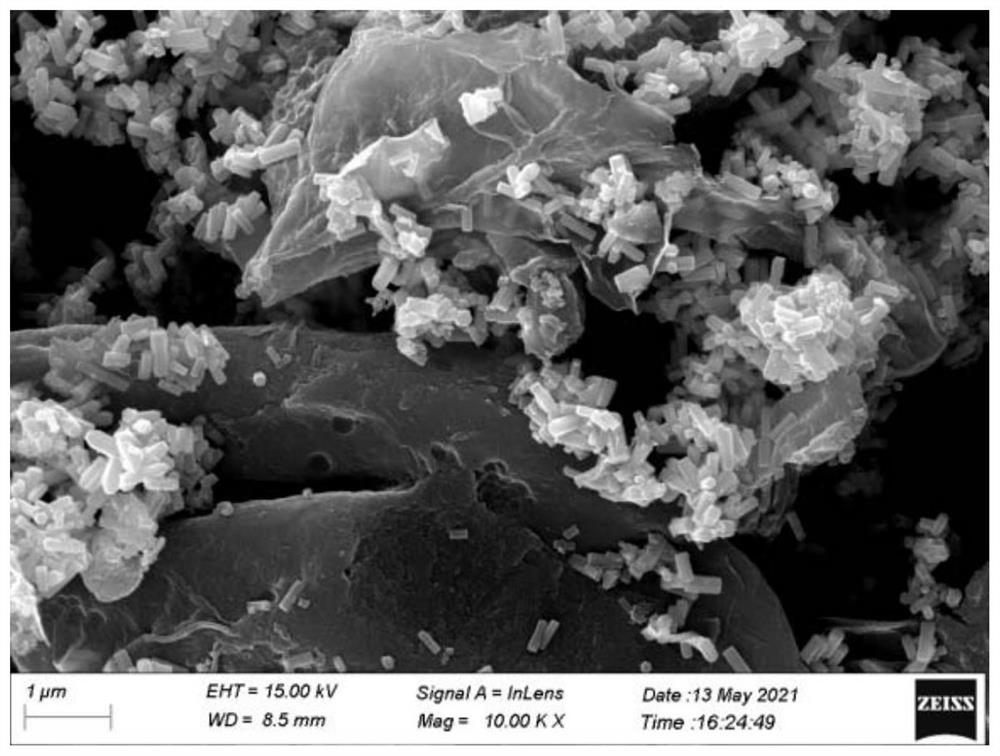

[0037] Example 3 Preparation of ZnO nanorod / biochar composite material

[0038] Disperse 0.115g (10%) of the biochar prepared in Example 2 in 30ml of ethanol, sonicate for 40min, then add 1.15g of zinc acetate dihydrate, add 3g of NaOH and 7.5ml of PEG 400 to the solution and sonicate for 40min. The solution was then transferred to a polytetrafluoroethylene-lined stainless steel autoclave, heated in an oven at 120 °C for 12 h, and cooled to room temperature naturally. The product ZnO / biochar nanocomposites were washed several times with distilled water and ethanol, and dried at 60 °C for 48 h for subsequent studies.

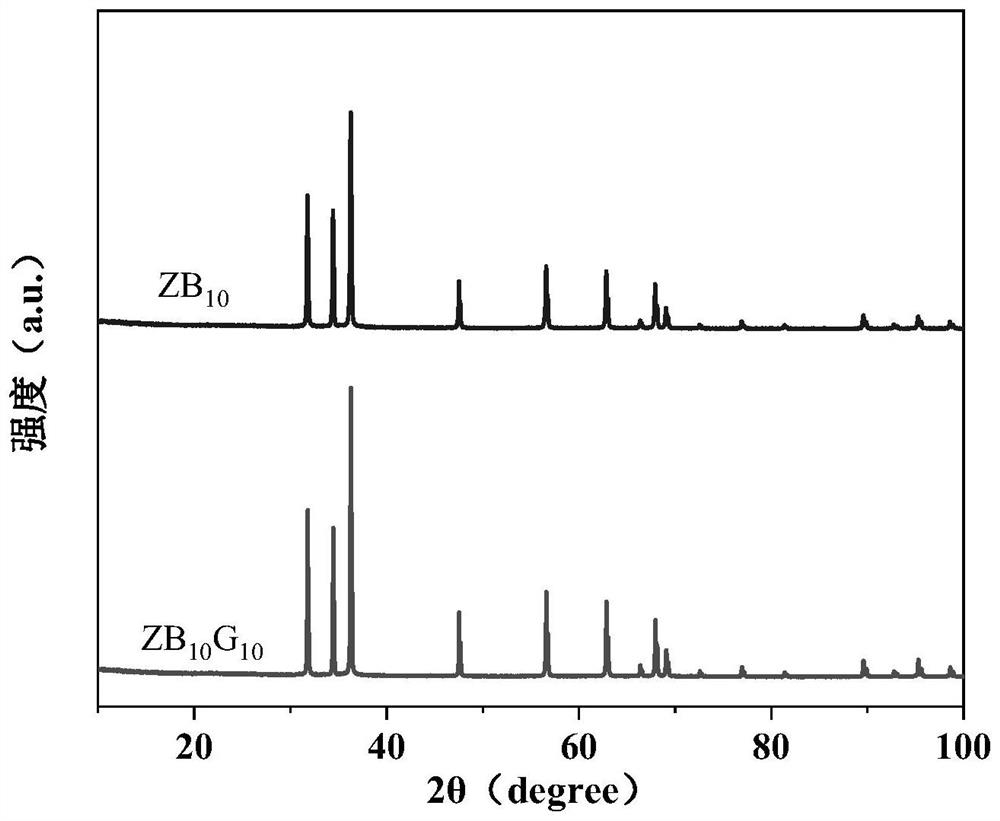

[0039] Using the biochar prepared in Example 2 of 0.0575g (5wt.%), 0.1150g (10wt.%) and 0.1725g (15wt.%) respectively, ZnO / biochar nanocomposites were prepared according to the above method, and the samples were respectively called ZB 5 、ZB 10 and ZB 15 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com