A kind of water-based flame retardant energy-saving anti-corrosion paint and preparation method thereof

An anti-corrosion coating, water-based technology, applied in anti-corrosion coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., can solve the problems of poor thermal insulation and energy saving, poor thermal insulation performance, increased water absorption, etc., and achieve good water resistance. , improve strength, improve the effect of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

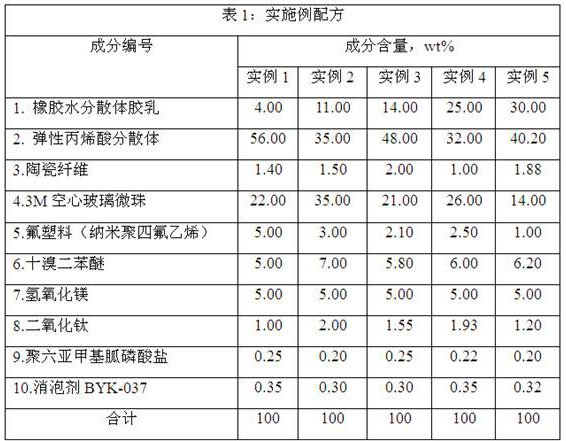

[0060] The preparation method of a water-based flame-retardant, energy-saving and anti-corrosion coating of the present invention has the following specific operation steps:

[0061] 1) Weigh 4.00-30.00 wt% rubber water dispersion latex, 32.00-56.00 wt% elastic acrylic dispersion, 0.30-0.35 wt% defoamer, 0.20-0.25 wt% polyhexamethylene by mass percentage The guanidine phosphate is added to the dispersion tank, and dispersed at a low speed for 5-10 minutes to obtain a uniform mixed solution I;

[0062] 2) Weigh 1.00-5.00 wt% fluoroplastic, 5.00-7.00 wt% decabromodiphenyl ether, 5.00 wt% magnesium hydroxide, 1.00-2.00 wt% titanium dioxide, 1.00-2.00 wt% The ceramic fibers are added to the mixed solution I in turn under low-speed stirring, and then dispersed at a high speed for 10-15 minutes until the mixing is uniform to obtain the mixture II;

[0063] 3) Add 14.00-35.00 wt% 3M hollow glass microsphere mixture (600 mesh glass microspheres and glass microspheres with a particle ...

Embodiment 1

[0067] 1) Weigh 4.00 parts of rubber water dispersion latex, 56.00 parts of elastic acrylic dispersion, 0.35 parts of defoamer BYK-0340, and 0.25 parts of polyhexamethylene guanidine phosphate into the dispersion tank, and disperse at a low speed of 300-500 r / min 5-10 minutes to obtain a uniform mixed solution I;

[0068] 2) Under stirring at a low speed of 300-500 r / min, 5.00 parts of fluoroplastics (nano-polytetrafluoroethylene), 5.00 parts of decabromodiphenyl ether, 5.00 parts of magnesium hydroxide, 1.00 parts of titanium dioxide, and 1.40 parts of ceramic fibers were added and mixed. In liquid I, disperse at a high speed of 1000-1500 r / min for 10-15 minutes, until the mixture is uniform, and obtain mixture II;

[0069] 3) Under the condition of stirring and dispersing at a low speed of 300-500 r / min, add 22.00 parts of the hollow glass microsphere mixture (the weight ratio of 600 mesh glass microspheres to glass microspheres with a particle size of 20-120 μm is 3:2) into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com