Benzyl methoxy-oleoyl quaternary ammonium surfactant as well as preparation method and application thereof

A technology of surfactant and oleoyl quaternary ammonium, which is applied in the field of benzyloxy-oleoyl quaternary ammonium surfactant and its preparation, can solve the problem of large, easy to decompose when exposed to water and high temperature to form toxic gases such as sulfur dioxide and hydrogen chloride , Limiting the scope of application, unfavorable environmental protection and other problems, to achieve the effect of low toxicity, avoiding toxic gas and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] A kind of preparation method of benzyloxy-oleoyl quaternary ammonium surfactant, comprises the following steps:

[0055] 1) fatty acid, anisole, FeCl 3 mixing and carrying out an alkylation reaction at 50-85° C. for 2-8 hours to obtain the first intermediate product;

[0056] 2) Mix the first intermediate product with 3-dimethylaminopropylamine and perform amidation reaction at 135-165° C. for 5-12 hours to obtain the second intermediate product;

[0057] 3) Mix the second intermediate product, chlorinated organic acid salt, and sodium carbonate in ethanol / water solution, and perform a quaternization reaction at 85-105°C for 6-12h to obtain benzyloxy-oleoyl quaternary ammonium type surfactants.

[0058] Among them, the fatty acid is oleic acid or its methyl ester, methyl oleate; fatty acid, anisole, FeCl 3 , 3-dimethylaminopropylamine, chlorinated organic acid salt, the molar ratio of sodium carbonate is 1:(3-8):(0.5-1.2):(1-3):(1-2):(1-2 ).

[0059] For the surfac...

Embodiment 1

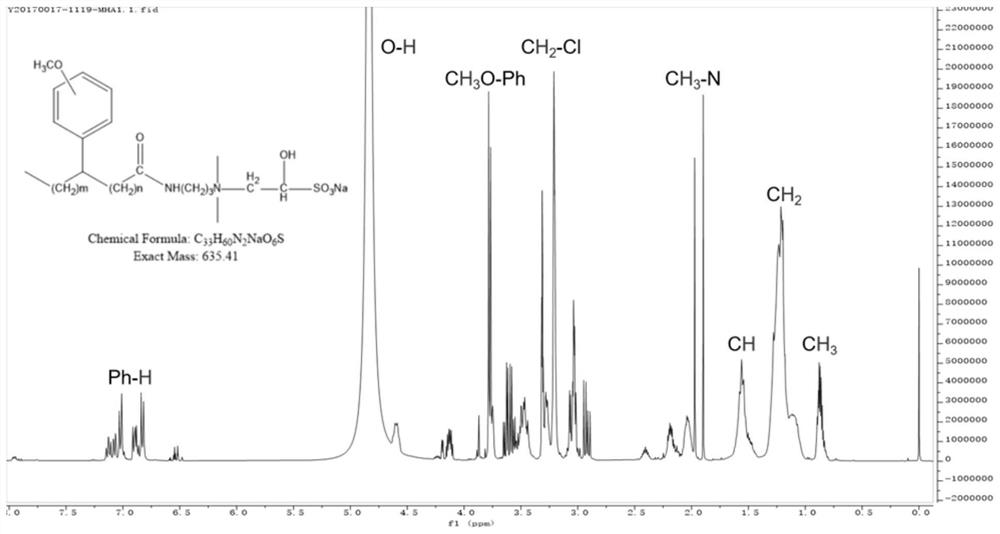

[0067] A kind of benzyloxy-oleoyl quaternary ammonium surfactant, its structural formula is as follows:

[0068]

[0069] The preparation method of this tensio-active agent comprises the following steps:

[0070] 1) Add 0.08mol anisole and 0.005mol catalyst FeCl to 0.01mol oleic acid 3 , and stirred at 65°C for 6h to obtain the first intermediate product;

[0071] 2) Add 0.03mol 3-dimethylaminopropylamine to 10mL ethylbenzene and mix well, then add the first intermediate product, and stir and react at 160°C for 5h, then distill off the unreacted 3-dimethylaminopropylamine, Ethylbenzene and anisole, obtain the second intermediate product;

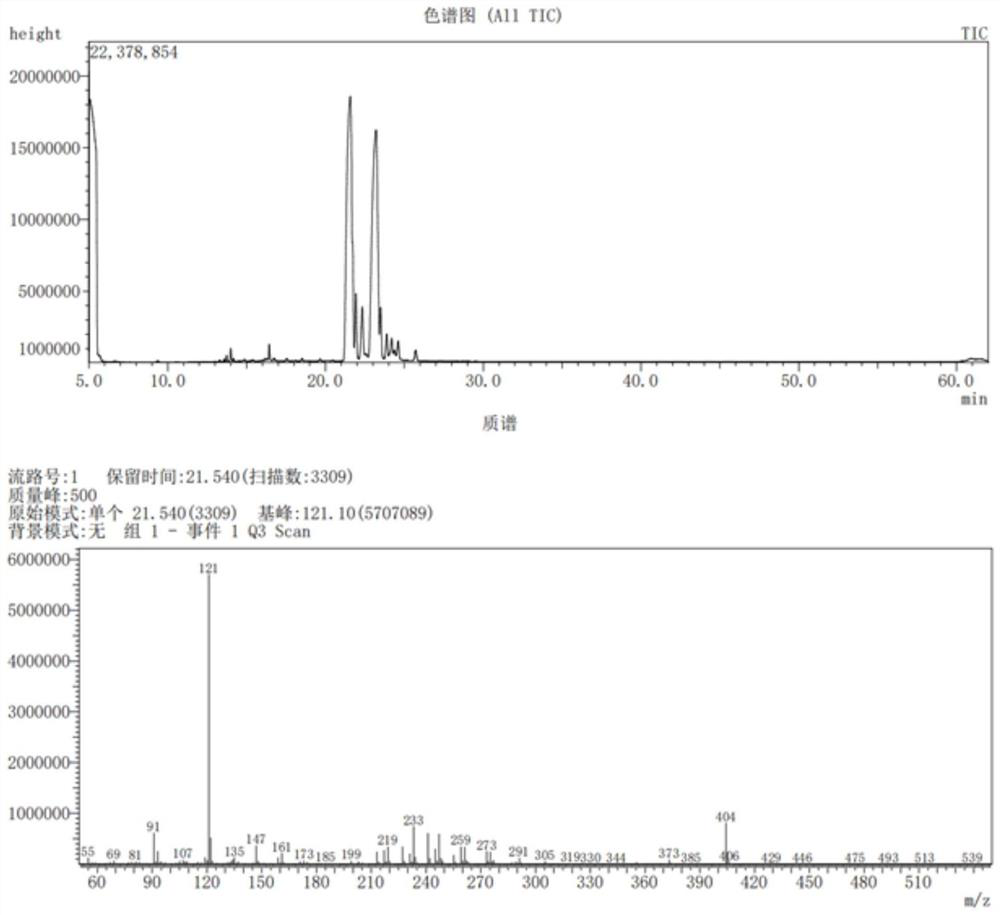

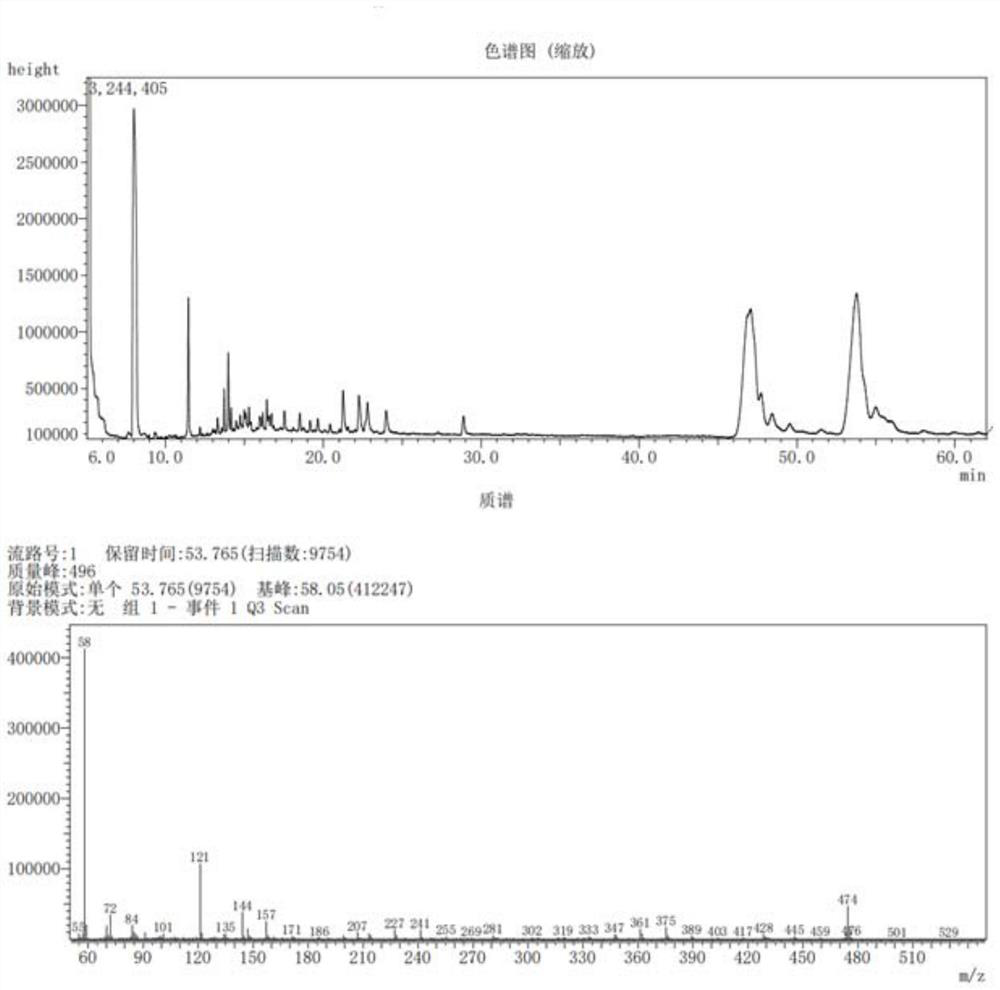

[0072] 3) Mix 30mL ethanol and 15mL water to prepare ethanol / water solution, then add the second intermediate product, 0.01mol Na 2 CO 3 and 0.012mol 3-chloro-2-hydroxypropanesulfonate, and stirred at 95°C for 10h, then evaporated to remove ethanol and water, and dissolved the remaining solid with methanol, separated the methanol phas...

Embodiment 2

[0076] A kind of benzyloxy-oleoyl quaternary ammonium surfactant, its structural formula is as follows:

[0077]

[0078] The preparation method of this tensio-active agent comprises the following steps:

[0079] 1) Add 0.03mol anisole and 0.01mol catalyst FeCl to 0.01mol oleic acid 3 , and stirred at 50°C for 8h to obtain the first intermediate product;

[0080] 2) Add 0.01mol 3-dimethylaminopropylamine to 10mL ethylbenzene and mix well, then add the first intermediate product, and stir and react at 160°C for 5h, then evaporate unreacted 3-dimethylaminopropylamine, Ethylbenzene and anisole, obtain the second intermediate product;

[0081] 3) Mix 30mL ethanol and 15mL water to prepare ethanol / water solution, then add the second intermediate product, 0.01mol Na 2 CO 3 and 0.02mol 3-chloro-2-hydroxypropanesulfonate, and stirred at 85°C for 6h, then evaporated to remove ethanol and water, and dissolved the remaining solid with methanol, separated the methanol phase, and evap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com