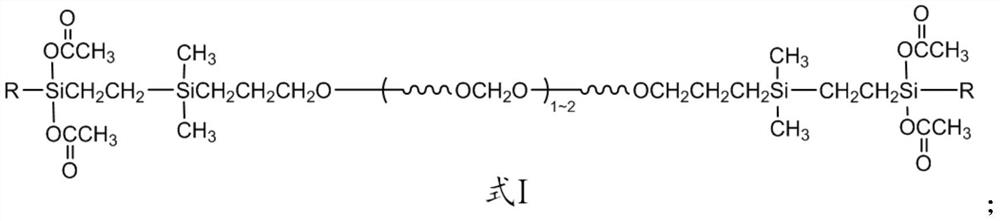

Silane modified polyether, preparation method and application thereof

A silane-modified polyether and polyether technology, applied in the field of sealants, can solve the problems of improving the difficulty of mixing process, prone to glue back, copper corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

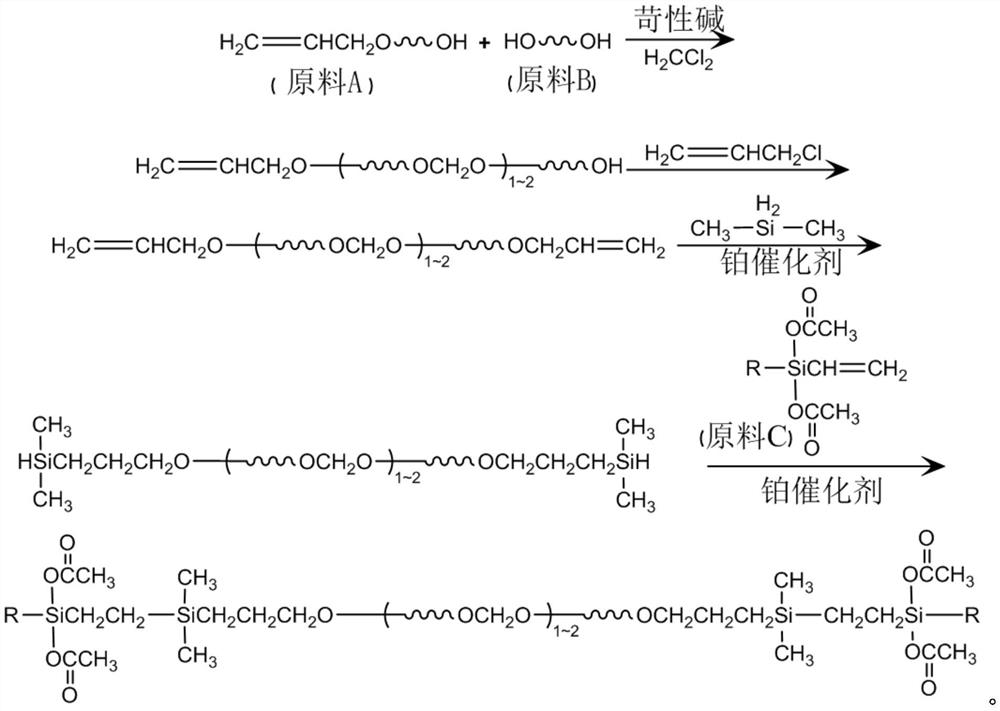

[0156] This embodiment has prepared a kind of silane modified polyether, and concrete process is:

[0157] S1. 1mol polyethylene glycol monoallyl ether (CAS: 27274-31-3, average molar mass 4000g / mol, purchased from Wuhan Huaxiang Kejie Biotechnology Co., Ltd.), 3mol polypropylene glycol (average molar mass 3000g / mol) and 2mol dichloromethane under the catalysis of caustic alkali (sodium hydroxide, 5mg / kg) chain extension polymerization (room temperature, 3h), then add 2mol allyl chloride after capping for 3h, vacuum evaporate at 80 ℃ Go out residual dichloromethane and allyl chloride, obtain the first intermediate;

[0158] S2. Perform a catalytic reaction of 1 mol of the first intermediate and 2.1 mol of dimethylsilane (the catalyst is chloroplatinic acid, CAS: 16941-12-1, the addition amount is 10 ppm), the temperature of the catalytic reaction is 80°C, and the time is 2h. Get the second intermediate;

[0159] S3. Catalytic addition reaction of 1 mol of the second interme...

Embodiment 2

[0161] This embodiment prepares a kind of silane modified polyether, the difference of specific process and embodiment 1 is:

[0162] (1) In step S1, polypropylene glycol (3000g / mol) is replaced with polyethylene glycol propylene glycol copolymer (4500g / mol);

[0163] (2) In step S3, vinylmethyldiacetoxysilane was replaced with vinyltriacetoxysilane (CAS: 4130-08-9).

Embodiment 3

[0165] This embodiment prepares a kind of silane modified polyether, the difference of specific process and embodiment 1 is:

[0166] (1) In step S1, replace polyethylene glycol monoallyl ether with allyl polyoxyethylene polyoxypropylene ether (CAS: 9041-33-2, average molar mass 4000g / mol, purchased from Wuhan Huaxiang Kejie Biotechnology Co., Ltd.);

[0167] (2) In step S1, polypropylene glycol (3000g / mol) is replaced by polypropylene glycol (4500g / mol);

[0168] (3) In step S3, vinylmethyldiacetoxysilane is replaced with vinyltriacetoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com