Graded radiation super-macroporous silicon dioxide nanosphere, and preparation method and application thereof

A silica and super-porous technology, applied in the field of nanomaterials, can solve the problem of lack of green, achieve the effect of not harsh process conditions, conducive to migration, and reduce volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

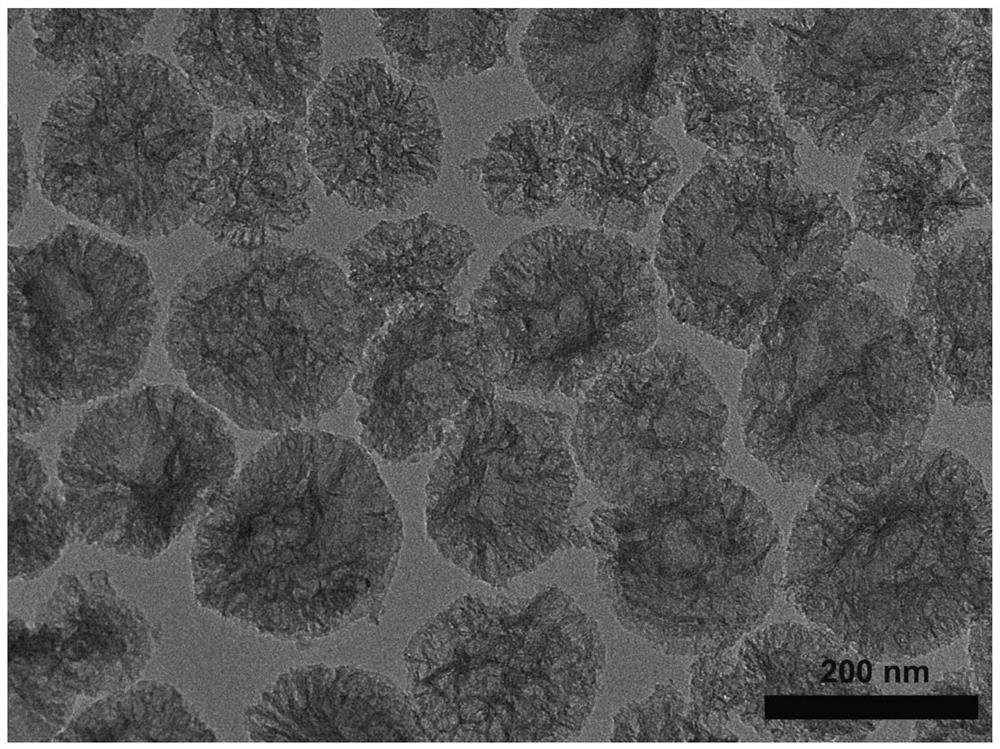

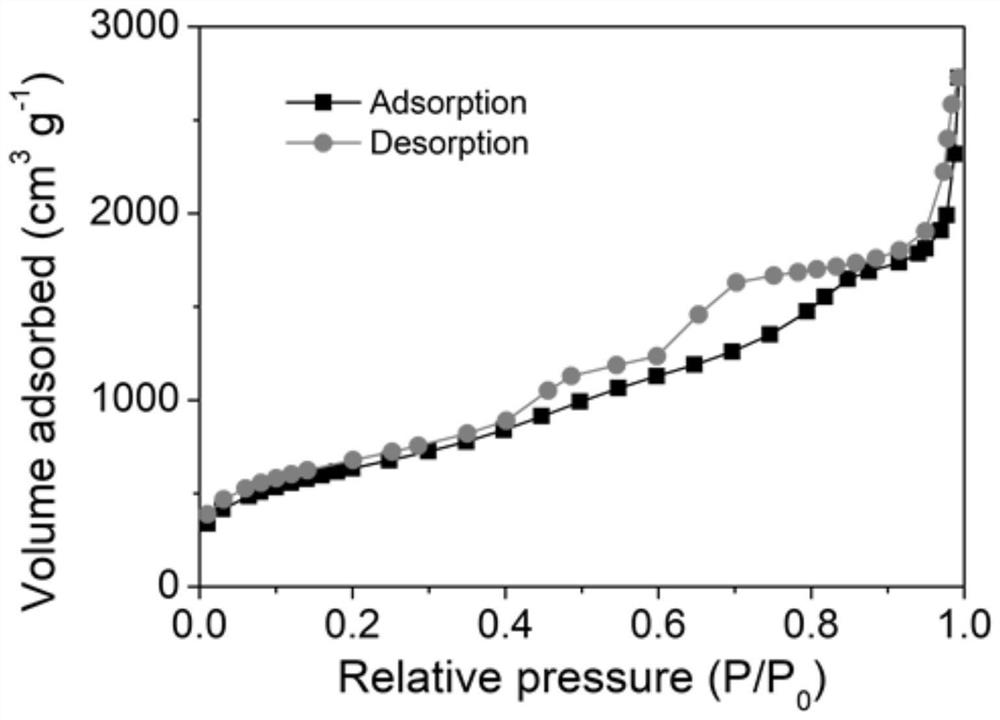

Embodiment 1

[0034] The preparation method of graded radiation ultra-macroporous silica nanospheres is as follows: mix 70mL deionized water, 20mL ether and 10mL absolute ethanol, add 0.5g CTAB (cetyltrimethylammonium bromide), and then add 0.8 mL of ammonia water, stirred for 30 minutes, so that CTAB is fully dissolved and the whole system is evenly mixed. Then add 2.5mL TEOS (tetraethyl orthosilicate), and stir vigorously at room temperature for 4 hours, so that the silicon source precursor is hydrolyzed and polymerized at the internal and external interfaces of the dispersant and ether emulsion droplets. Afterwards, the hydrolysis reaction product was suction-filtered, washed three times with deionized water and absolute ethanol, and then dried in an oven at 50°C, and then refluxed with ethanol solution of hydrochloric acid to remove CTAB. During this process, the surfactant successfully introduced the mesoporous structure into the radiative hierarchical structure, and the hydrolysis of ...

Embodiment 2

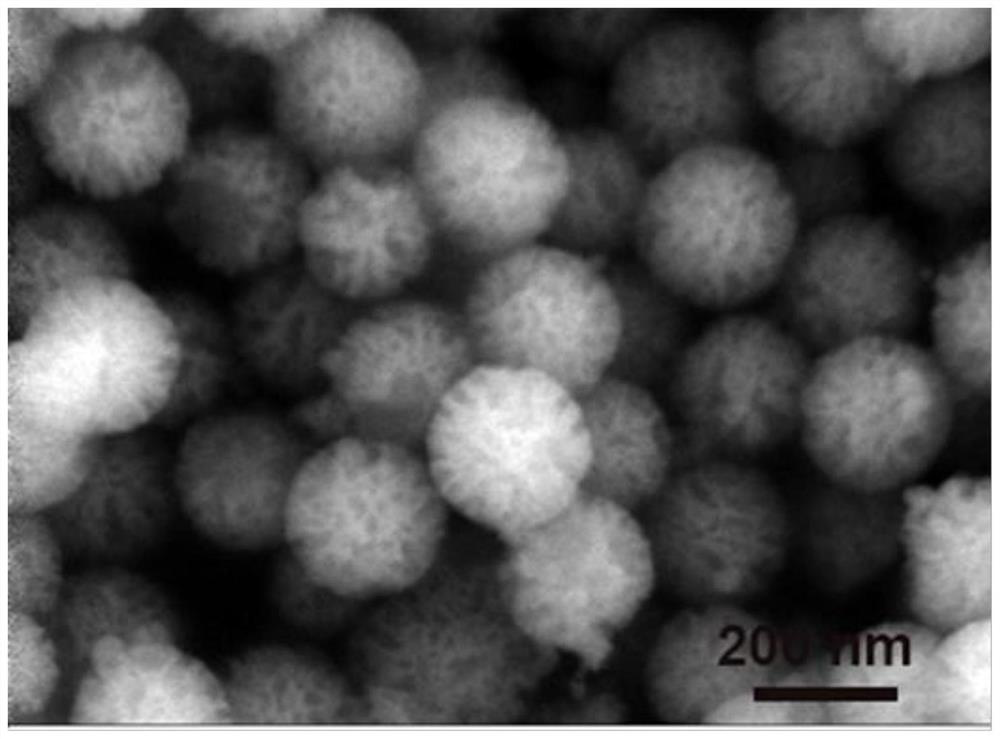

[0039]The preparation method of graded radiation ultra-macroporous silica nanospheres is as follows: mix 70mL deionized water, 10mL ether and 20mL ethanol, add 0.5g CTAB (cetyltrimethylammonium bromide), and then add 0.8mL ammonia water , stirred for 30 minutes, so that CTAB is fully dissolved and the whole system is evenly mixed. Then add 2.5mL TEOS (tetraethyl orthosilicate), and stir vigorously at room temperature for 4 hours, so that the silicon source precursor is hydrolyzed and polymerized at the internal and external interfaces of the dispersant and ether emulsion droplets. Afterwards, the hydrolysis reaction product was suction-filtered, washed three times with deionized water and absolute ethanol, and then dried in an oven at 50°C, and then refluxed with ethanol solution of hydrochloric acid to remove CTAB. During this process, the surfactant successfully introduced the mesoporous structure into the radiative hierarchical structure, and the hydrolysis of the silicon s...

Embodiment 3

[0041] The preparation method of hierarchical radiation ultra-large porous silica nanospheres is as follows: mix 70mL deionized water, 5mL ether and 25mL ethanol, add 0.5g CTAB (cetyltrimethylammonium bromide), and then add 0.8mL ammonia water , stirred for 30 minutes, so that CTAB is fully dissolved and the whole system is evenly mixed. Then add 2.5mL TEOS (tetraethyl orthosilicate), and stir vigorously at room temperature for 4 hours, so that the silicon source precursor is hydrolyzed and polymerized at the internal and external interfaces of the dispersant and ether emulsion droplets. Afterwards, the hydrolysis reaction product was suction-filtered, washed three times with deionized water and absolute ethanol, and then dried in an oven at 50°C, and then refluxed with ethanol solution of hydrochloric acid to remove CTAB. During this process, the surfactant successfully introduced the mesoporous structure into the radiative hierarchical structure, and the hydrolysis of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com