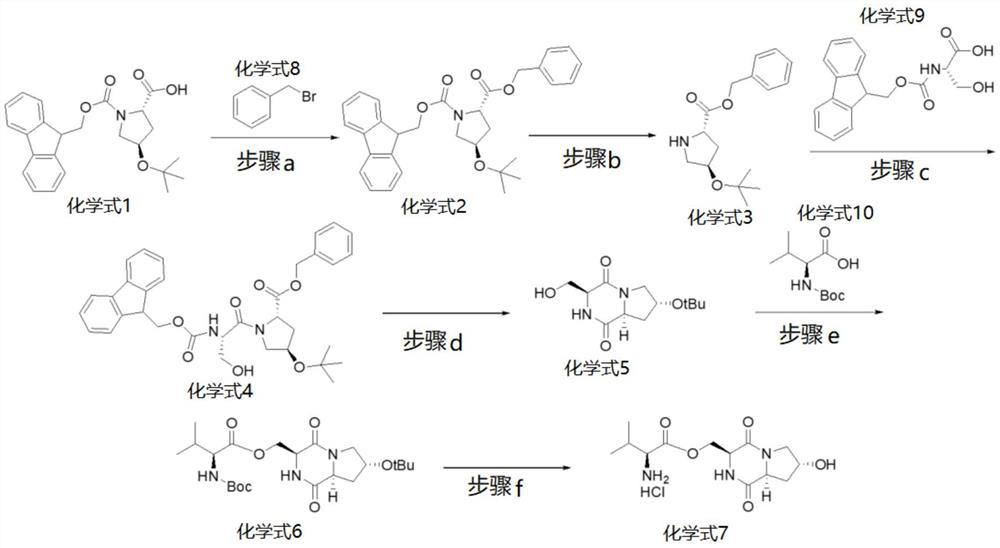

Preparation method of cyclo-trans-4-L-hydroxyprolyl-L-serine-O-amino-acid ester hydrochloride

A technology of hydroxyprolyl and amino acid esters, applied in the field of drug preparation, can solve problems such as unsuitability for large-scale production, difficulty in separating intermediates, and low product purity, and achieve easy control of the reaction process, optimization of the production process, and simplification of operations The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. step a: the synthesis of the compound shown in chemical formula 2

[0044] Dissolve Fmoc-Hyp(t-Bu)-OH (i.e. the compound shown in Chemical Formula 1, 50g, 1.0eq) in DMF (250mL), add sodium carbonate (20.25g) and stir for 10min, then add benzyl bromide (i.e. Chemical Formula 8 The shown compound, 25.06g), was reacted at room temperature for 16h, and filtered with diatomaceous earth after the reaction was completed. The filtrate was concentrated and separated by column chromatography to obtain the compound shown in Chemical Formula 2 with a yield of 100%.

[0045] 2. Step b: Synthesis of the compound shown in Chemical Formula 3

[0046] The compound shown in Chemical Formula 2 (61g, 1.0eq) was dissolved in DCM solution (5v / w) containing 25% ethylenediamine, and reacted at room temperature for 3h. After the reaction was detected by TLC, the solvent was removed, and ethyl acetate and water were added. Extracted three times, extracted once with saturated sodium bicarbon...

Embodiment 2

[0056] 7. Step a: Synthesis of the compound shown in Chemical Formula 2

[0057] Dissolve Fmoc-Hyp(t-Bu)-OH (50g, 1.0eq) in DMF (250mL), add sodium bicarbonate (25.36g) and stir for 10min, then add benzyl bromide (25.06g), react at room temperature for 16h, After the reaction was completed, it was filtered with diatomaceous earth. The filtrate was concentrated and separated by column chromatography to obtain the compound shown in Chemical Formula 2 with a yield of 100%.

[0058] 8. Step b: Synthesis of the compound shown in Chemical Formula 3

[0059] The compound shown in Chemical Formula 2 (61g, 1.0eq) was dissolved in a tetrahydrofuran solution (5v / w) containing 25% ethylenediamine, and reacted at room temperature for 3h. After the reaction was detected by TLC, the solvent was removed, and ethyl acetate and water were added. Extracted three times, extracted once with saturated sodium bicarbonate solution, extracted once with saturated saline, dried and filtered the organi...

Embodiment 3

[0069] 13. Step a: Synthesis of the compound shown in Chemical Formula 2

[0070] Dissolve Fmoc-Hyp(t-Bu)-OH (50g, 1.0eq) in acetonitrile (250mL), add sodium carbonate (20.25g) and stir for 10min, then add benzyl bromide (27.58g), react at room temperature for 16h, and react After the end, filter with celite. The filtrate was concentrated and separated by column chromatography to obtain the compound shown in Chemical Formula 2 with a yield of 100%.

[0071] 14. Step b: Synthesis of the compound shown in Chemical Formula 3

[0072] The compound shown in Chemical Formula 2 (61g, 1.0eq) was dissolved in a tetrahydrofuran solution (5v / w) containing 25% ethylenediamine, and reacted at room temperature for 3h. After the reaction was detected by TLC, the solvent was removed, and ethyl acetate and water were added. Extracted three times, extracted once with saturated sodium bicarbonate solution, extracted once with saturated saline, dried and filtered the organic phase, concentrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com