Lipoic acid mixed micelle as well as preparation method and application thereof

A technology of mixing micelles and lipoic acid, which is applied in drug combinations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of inconvenient product processing and preparation, low bioavailability, weak solubility, etc., to improve the overall antioxidant capacity, biological The effect of good compatibility and simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A lipoic acid mixed micelle, its preparation method comprises the following steps:

[0026] Weigh 150mg of soybean lecithin and 50mg of lipoic acid into a 50mL round bottom flask, then add 10mL of methanol therein for dissolution, and ultrasonically disperse evenly. When the temperature of the water bath is 40°C, the methanol is removed by rotary evaporation to form a layer of transparent lipoic acid micellar coprecipitate film. Dissolve 50 mg of sodium lipoic acid in 10 mL of purified water to obtain a mixed solution, and add the mixed solution to the above transparent film. Thin film, obtain the dispersion solution of drug-containing mixed micelles, probe ultrasonic (50W, interval 2s, 2min), then filter with 0.22μm microporous membrane, take filtrate, pack separately, obtain lipoic acid mixed micelles.

Embodiment 2

[0028] A lipoic acid mixed micelle, its preparation method comprises the following steps:

[0029] Weigh 150 mg of soybean lecithin and 50 mg of lipoic acid into a 50 mL round-bottomed flask, then add 10 mL of dichloromethane to dissolve it, and disperse evenly by ultrasonication. When the temperature of the water bath is 35°C, dichloromethane is removed by rotary evaporation, forming a layer of transparent lipoic acid micellar co-precipitate film, dissolving 50 mg of sodium lipoic acid in 10 mL of purified water to obtain a mixed solution, and adding the mixed solution to the above transparent film Hydrate the film in neutral to obtain a dispersion solution of drug-containing mixed micelles. Ultrasonic the probe (50W, interval 2s, 2min), then filter with a 0.22μm microporous membrane, take the filtrate and subpackage to obtain lipoic acid mixed micelles.

Embodiment 3

[0031] A lipoic acid mixed micelle, its preparation method comprises the following steps:

[0032] Weigh 150 mg of soybean lecithin and 50 mg of lipoic acid into a 50 mL round-bottomed flask, then add 10 mL of ethanol to dissolve it, and disperse evenly by ultrasonication. When the temperature of the water bath is 45°C, the ethanol is removed by rotary evaporation to form a layer of transparent lipoic acid micellar coprecipitate film. Dissolve 100 mg of sodium lipoic acid in 10 mL of purified water to obtain a mixed solution, and add the mixed solution to the above transparent film. Thin film, obtain the dispersion solution of drug-containing mixed micelles, probe ultrasonic (50W, interval 2s, 2min), then filter with 0.22 μm microporous membrane, take filtrate, pack separately, obtain lipoic acid mixed micelles.

PUM

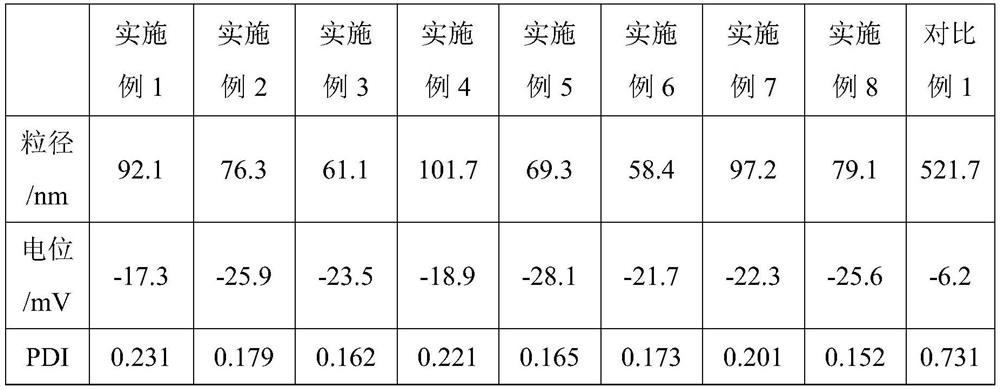

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com