Testing method for detecting low-melting-point material by glow discharge mass spectrometry

A technology of glow discharge mass spectrometry and testing method, which is applied in the field of glow discharge mass spectrometry to detect low melting point materials, which can solve problems such as solid samples are easy to melt, drip into the instrument, damage the instrument and pollute, and reduce the pre-sputtering time , Small matrix effect, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A test method for detecting low melting point materials by glow discharge mass spectrometry, comprising the steps of:

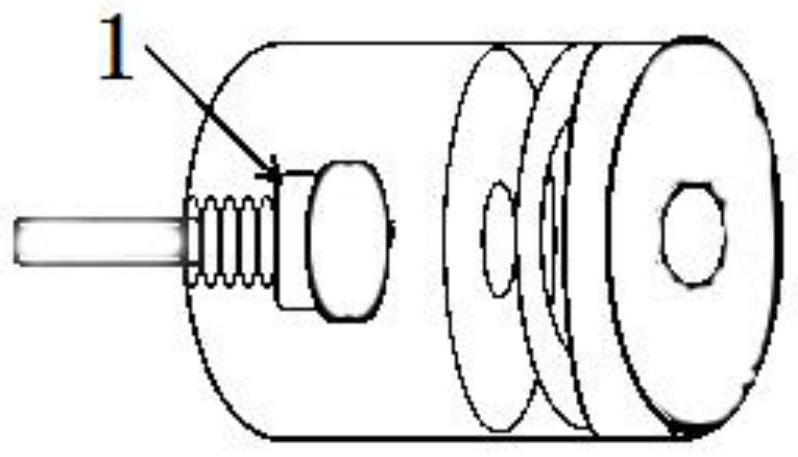

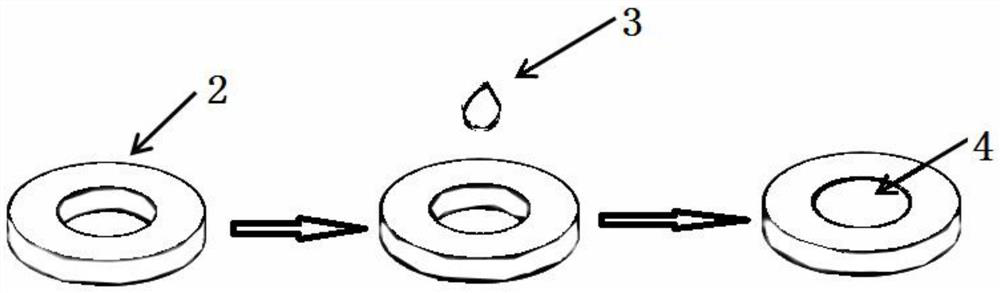

[0037] Step 1. Using high-purity tantalum to make a tantalum carrier with a circular groove in the middle;

[0038] Step 2. Put the tantalum carrier into the mixture of concentrated nitric acid, hydrogen fluoride and water for pickling, then soak for 30s, then wash it with ultrapure water once, and then put it into the mixture of concentrated sulfuric acid, hydrogen peroxide and water to acid again Wash, then ultrasonicate three times with deionized water and absolute ethanol successively, each time for 1min, and then blow dry with compressed air to obtain the treated tantalum carrier;

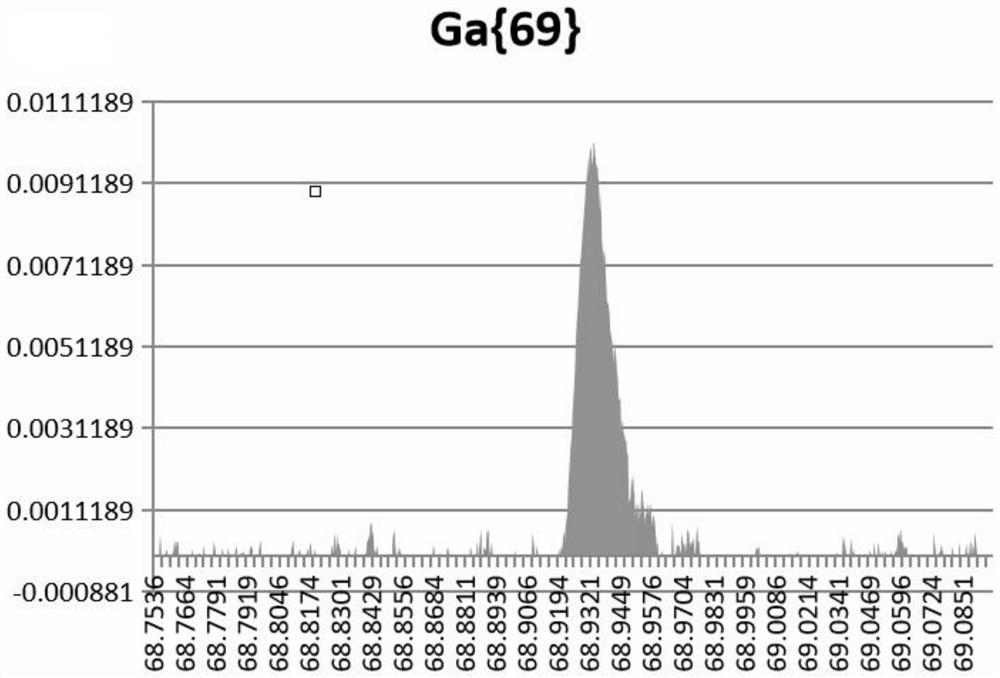

[0039] Step 3. Put the gallium indium tin alloy in a clean beaker, put it into an oil bath in hot oil or a water bath in hot water, and make it fully melt to obtain a liquid gallium indium tin alloy, and then take an appropriate amount of liquid gallium indium tin allo...

Embodiment 2

[0048] A test method for detecting low melting point materials by glow discharge mass spectrometry, comprising the steps of:

[0049] Step 1. Using high-purity metal to make a metal carrier with a circular groove in the middle;

[0050] Step 2: Put the metal carrier into the mixture of concentrated nitric acid, hydrogen fluoride and water for pickling, then soak for 30s, then wash it with ultrapure water once, and then put it into the mixture of concentrated sulfuric acid, hydrogen peroxide and water to pickle again Wash, then ultrasonicate three times with deionized water and absolute ethanol successively, each time for 1min, and then blow dry with compressed air to obtain the treated metal carrier;

[0051] Step 3. Put the low melting point material in a clean beaker, put it into an oil bath in hot oil or a water bath in hot water, make it fully melt, and obtain a liquid low melting point material, and then take an appropriate amount of liquid low melting point material and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com