Temperature-resistant and salt-resistant nano imbibition agent as well as synthesis method and application thereof

A temperature-resistant, salt-resistant, synthetic method technology, applied in chemical instruments and methods, earth drilling, silicon organic compounds, etc., can solve weak physical effects, difficult low-permeability oil reservoir imbibition recovery effect, and interaction is easily damaged and other problems, to achieve the effect of good dispersion and stability, not easy to agglomerate, and large steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] 1.1 Preparation of lipophilic capillary

[0045] 1.1.1 Capillary specification: the standard capillary inner diameter is 0.5 mm, and ultrasonically treat with carbon tetrachloride, benzene: acetone: ethanol = 7:1.5:1.5 (volume ratio) for 30 minutes to remove surface organic matter;

[0046] 1.1.2 Then use dilute hydrochloric acid solution (1:10) and hydrofluoric acid solution (10%) for ultrasonication to roughen and activate the capillary surface for 30 min; use deionized water for ultrasonic cleaning to remove residual acid until pH>6.5, dry at 105°C;

[0047] 1.1.3 Prepare the aging oil according to the ratio. The aging oil is composed of crude oil: aviation kerosene: 90# asphalt = 2:5:3; completely immerse the treated capillary in the aging oil, and age at 60°C for 2 to 4 weeks ;

[0048] 1.1.4 Take out the capillary and infiltrate it with kerosene for 2 minutes to clean the asphalt deposited on the inner and outer walls of the capillary, as long as it does not aff...

Embodiment 1

[0075] 150g BrCH 2 CH 2 OSi(OCH 2 CH 3 ) 3 Add 50g of N-methylimidazole and 500g of tetrahydrofuran into a 1000mL airtight reactor. The airtight reactor is equipped with a thermometer and a condensation reflux device. Nitrogen is passed through to remove oxygen, and the temperature is raised to 50°C for reflux for 2 hours. Rotary evaporator evaporates After removing the solvent, intermediate 1 was obtained;

[0076] 70g intermediate 1, 105g C 4 h 9 OCH 2 CH 2 OCH 2 CH 2 OH was sequentially added to a 1000mL four-necked flask containing 420g of acetonitrile, and after being fully dissolved, 11.9g of a 30% KOH solution was added to the reaction system to adjust the pH of the system to 8, and the reaction temperature was reduced at 60°C Vacuumize the reaction for 2h to obtain intermediate 2;

[0077] 150g intermediate 2, 60g BrCH 2 COONa was sequentially added to 240g tetrahydrofuran, and then 0.135g of ionic liquid [Bmim]BF was added to the system 4 , after being full...

Embodiment 2

[0081] 150g BrCH 2 CH 2 OSi(OCH 2 CH 3 ) 3 Add 75g of N-methylimidazole and 375g of dimethyl sulfoxide into a 1000mL closed reactor. The closed reactor is equipped with a thermometer and a condensation reflux device. Nitrogen is used to remove oxygen, and the temperature is raised to 60°C for 3h under reflux. After the solvent is evaporated by the evaporator, the intermediate 1 is obtained;

[0082] 75g intermediate 1, 100g C 8 h 17 O(CH 2 CH 2 O) 4 CH 2 CH 2 OH was sequentially added into a 1000mL four-necked flask containing 300g of toluene. After fully dissolving, 11.6g of 30% ammonia solution was added to the reaction system to adjust the pH of the system to 9, and the reaction temperature was reduced at 70°C. Vacuum reaction for 3h to obtain intermediate 2;

[0083] 150g intermediate 2, 75g BrCH 2 COONa is added in the 200g acetonitrile successively, then adds the ionic liquid [Bmim][CF of 0.2125g in the system 3 SO 3 ], after being fully dissolved, react a...

PUM

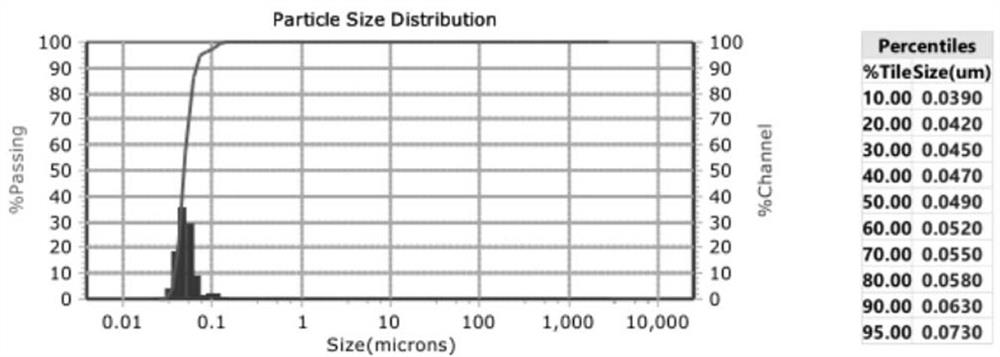

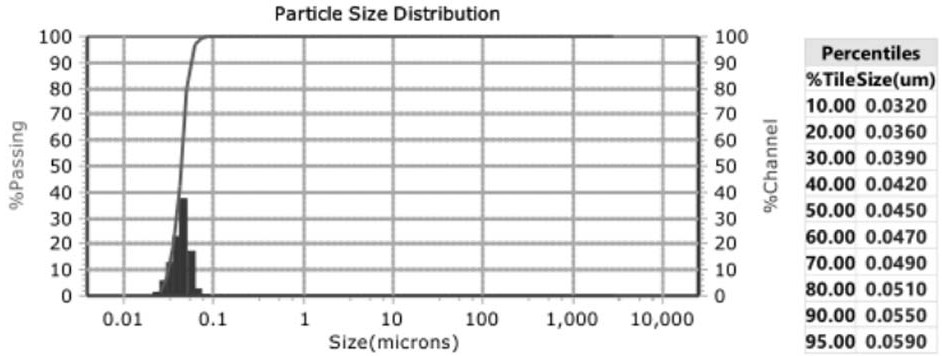

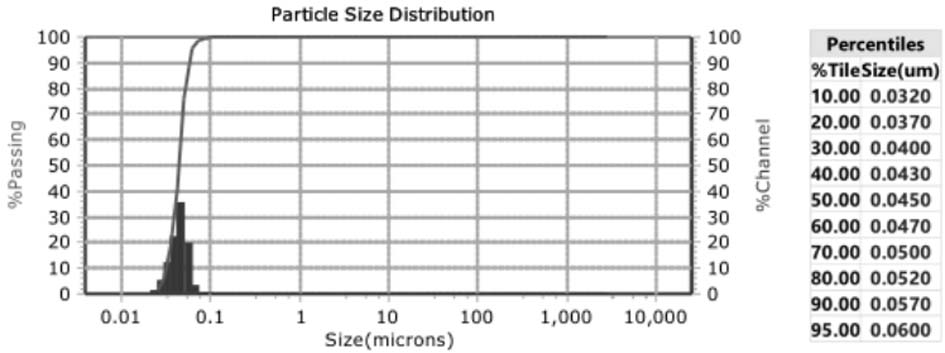

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com