Doped perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of photoelectric conversion efficiency and stability loss of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a preparation method of a doped perovskite solar cell, comprising the following steps:

[0039] A) depositing the first charge transport material on the substrate, and obtaining the first charge transport layer after annealing;

[0040] B) coating a doped perovskite precursor solution on the surface of the first charge transport layer, and obtaining a passivated perovskite layer after annealing;

[0041] The doped perovskite precursor solution includes inorganic salts, organic salts, self-healing polymers and solvents;

[0042] C) depositing a second charge transport material on the passivation perovskite layer to obtain a second charge transport layer;

[0043] D) Evaporating an electrode layer on the surface of the second charge transport layer to obtain a doped perovskite solar cell.

[0044]In the present invention, the substrate is preferably firstly cleaned with ethanol, isopropanol and acetone for 30-40 minutes, and dried wit...

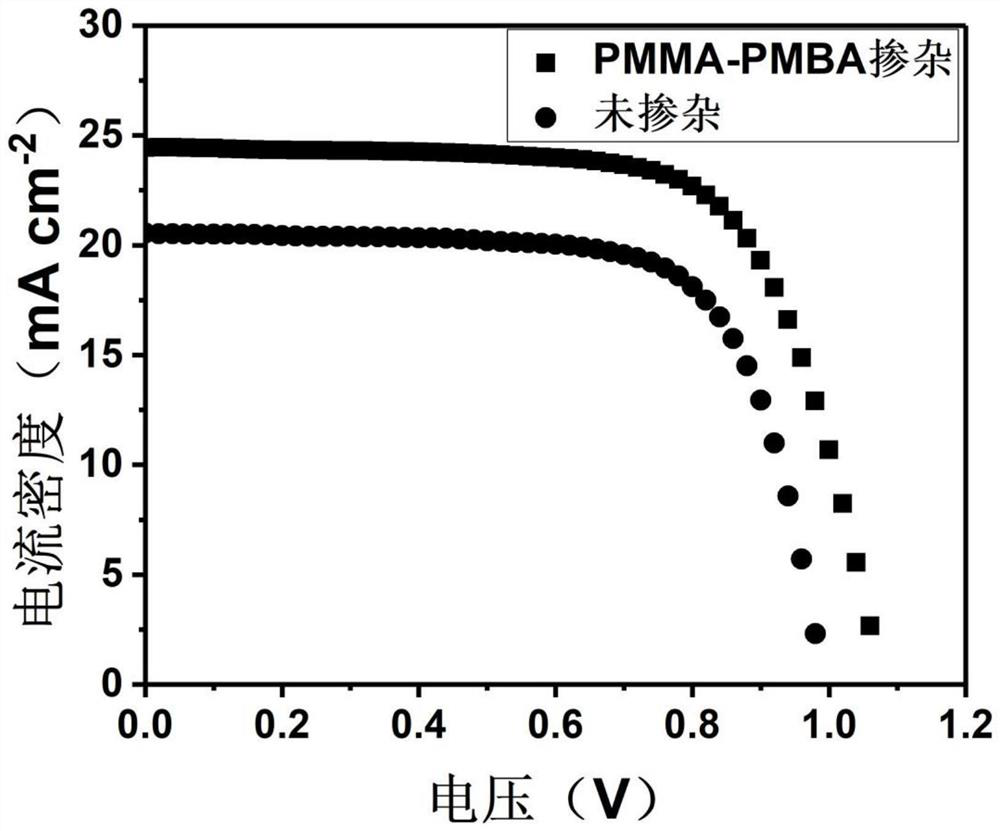

Embodiment 1

[0062] Step 1, wash 1.5*1.5cm indium tin oxide (ITO) glass with ethanol, isopropanol (IPA) and acetone for 30 minutes respectively, and blow dry with a nitrogen gun.

[0063] Step 2, the purchased tin dioxide (SnO 2 ) stock solution and ultrapure water according to the volume ratio of 1:5 diluted, fully stirred to obtain SnO 2 Precursor solution takes 50 μL SnO 2 The precursor solution is evenly spread on the surface of the ITO conductive glass, and the parameters of the homogenizer are set to 4000rpm / s, and the time is 30s. Then place it on a hot stage at 150°C for 30 minutes to obtain SnO 2 film.

[0064] In step 3, the film obtained in step 2 was placed in a UV-ozone cleaner for 30 minutes, ready for subsequent spin coating.

[0065] Step 4: Weigh 461mgPbI 2 Dissolve 150 mg MAI in 600 μL of DMF, heat and stir at 70°C to fully dissolve, add 15 μL PMMA-PMBA to obtain a perovskite precursor solution.

[0066] Step 5: Take 50 μL of perovskite precursor solution and evenly...

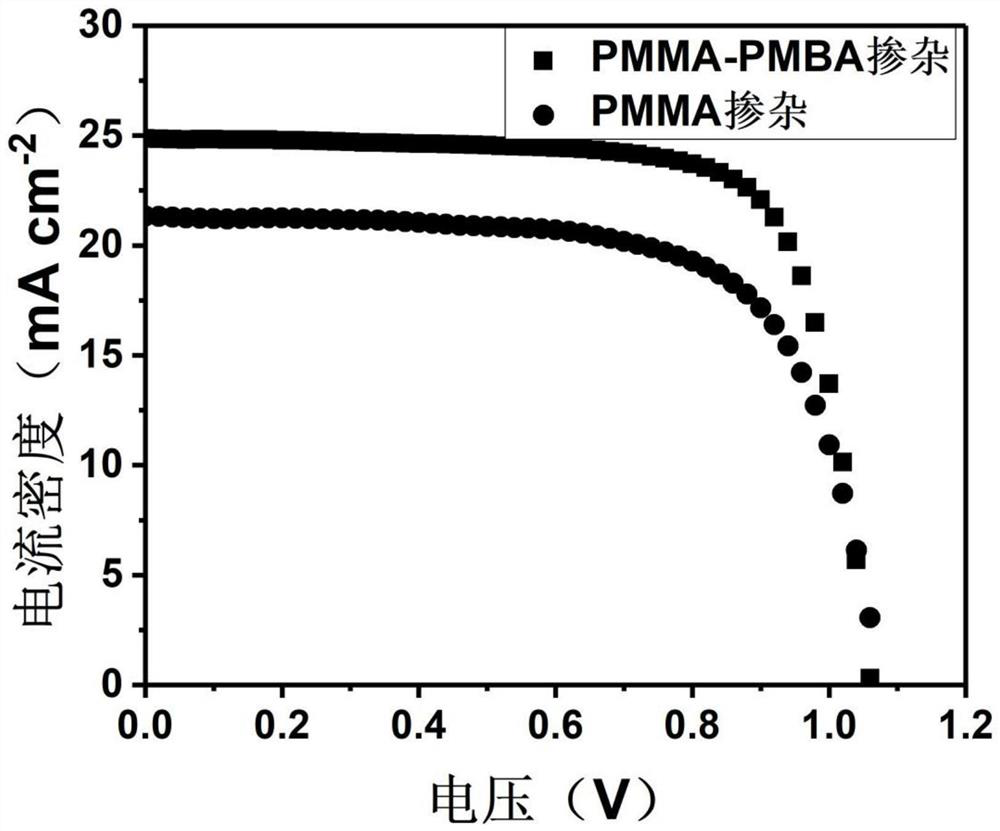

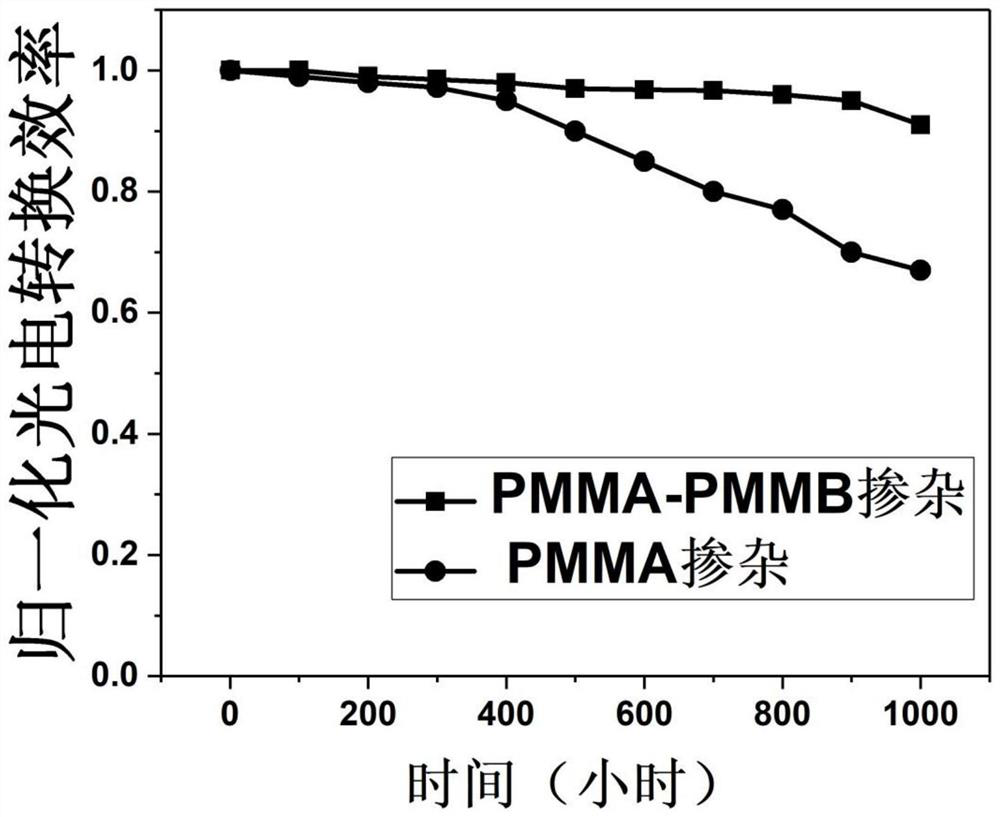

Embodiment 2

[0071] Step 1, wash 4*4cm FTO thin film glass with ethanol, isopropanol (IPA) and acetone for 30 minutes respectively, and blow dry with nitrogen gun.

[0072] Step 2, using magnetron sputtering method to sputter a layer of dense NiO on the surface of FTO thin film glass x Thin film (thickness ~ 20nm), sputtering power is 80W, 30min.

[0073] In step 3, the film sputtered in step 2 is treated with oxygen plasma for 10 min.

[0074] Step 4, weighing 6g lead iodide (PbI 2 ) and 0.57g cesium bromide (CsBr), 1.15g methylamine iodide (FAI) were dissolved in 10mL N,N-dimethylformamide (DMF) solution, stirred at room temperature for 6h to dissolve, and 50μL PMMA-PMBA was added to obtain perovskite ore precursor solution. Take 140 μ of the above perovskite precursor solution and evenly distribute it between the base and the scraper, and set the thickness of the scraper to 300 μm to complete the film scraping. Then place it on a hot stage at 150°C for 25 minutes to obtain a perovsk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com