Multistage structure carbon material, preparation method thereof and anticorrosive paint

A technology of anti-corrosion coatings and carbon materials, applied in anti-corrosion coatings, electrophoretic coatings, coatings, etc., can solve problems such as inability to provide long-term protection, accelerated corrosion of metal substrates, and unsatisfactory anti-corrosion effects, and achieve strong bonding and prolonged anti-corrosion Performance, the effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Based, the present invention provides a method of preparing a multi-stage structural carbon material, comprising the steps of:

[0054] Step (1), mix the saccharide organic matter, surfactant, and polar solvent, resulting in a first mixture, and the first mixture is soluble, and the flowering carbon material is obtained;

[0055] Specifically, in some embodiments, the sugar organic matter comprises at least one of glucose, fructose, sucrose, xylose, galactose, cyclodextrin, the concentration of sugar organics is 0.05 g / mL ~ 0.2 G / mL; the surfactant includes one or more of an alkyl trimethyl bromide, the alkyl group is one or more of the alkyl groups of 12 to 18, and the surfactant concentration is 0.5. Mg / mL ~ 5 mg / ml; the polar solvent comprises at least one of water, formamide, trifluoroacetic acid, DMSO, acetonitrile, DMF, and hexamethyl phosphoride.

[0056] In the step (1), the saccharide organic matter and the surfactant are hot at 120 ° C to 200 ° C for 6 h t...

Embodiment 1

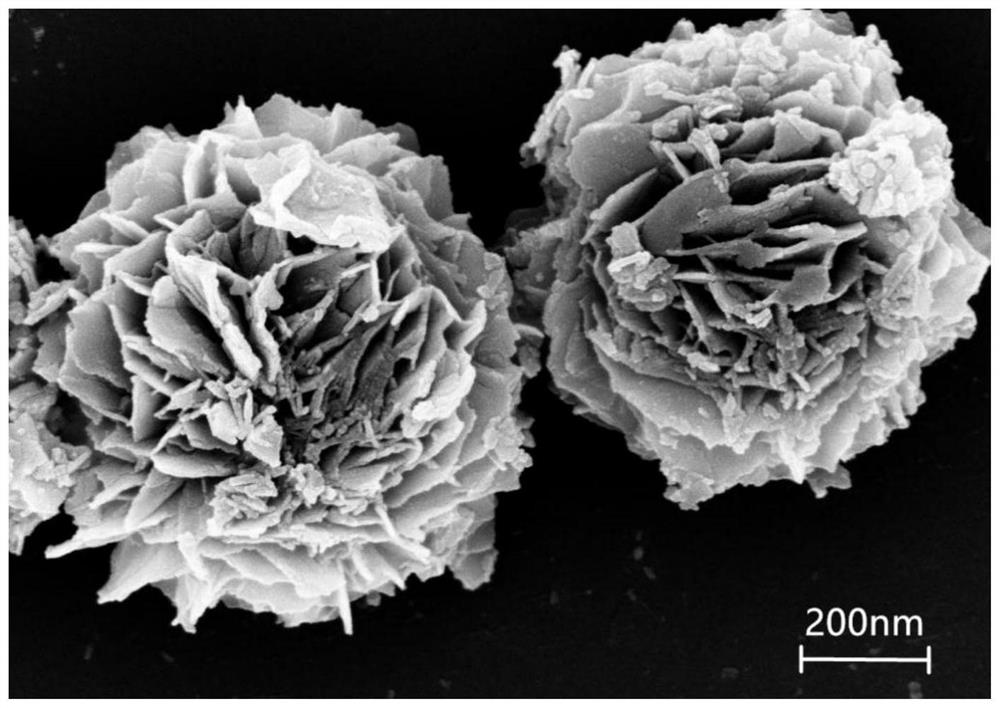

[0073] (1) 4 g of glucose and 80 mg of hexamethyltrimethyla bromide were dissolved in 40 ml of deionized water, stirred well, then transferred to a hydrothermal kettle with a capacity of 50 ml of polytetrafluoroethylene liner, The heat reaction was at 160 ° C for 12 h, and after the reaction was completed and cooled to room temperature, the reaction liquid was centrifuged at 4000 r / min to 40 min, washed three times, and dried at 60 ° C for 2 h to obtain a flower carbon material;

[0074] (2) Put the flowered carbon material obtained in step (1) in the tube furnace, and calcined at 900 ° C for 1 h, 900 ° C, to obtain a flower-carbon material;

[0075] (3) 80 mg of naphthalenesulfonic acid was dissolved in 40 mL, 0.5 mol / L of sodium hydroxide solution, and then the flowered carbon material obtained in the 80 mg step (2) was added thereto, and the mixture was stirred and dispersed, and then the liquid transfer In the hydrothermal hem of the polytetrafluoroethylene liner having a ...

Embodiment 2

[0078] (1) 2 g of sucrose and 200 mg of dodecyl trimethyl bromide were dissolved in 40 ml of deionized water, stirred well, and then transferred to a hydrothermal kettle with a polytetrafluoroethylene liner having a capacity of 50 mL. The heat reaction was at 120 ° C for 24 h, and after the reaction was completed and cooled to room temperature, the reaction liquid was centrifuged at 3000 r / min splitter for 5 min, washed three times, and dried at 40 ° C for 3 h, resulting in a flower carbon material;

[0079](2) Place the flower carbon material obtained in step (1) is placed in a tube furnace, and 0.5 h is calcined at a high temperature at a nitrogen atmosphere, and a flowered carbon material is obtained.

[0080] (3) 20 mg of nitro-nitroxia was dissolved in 40 mL, 0.1 mol / L ammonia water, and then 40 mg of step (2) was added thereto, and the flowered carbon material obtained in step (2) was added, and the mixture was thoroughly stirred, and then the liquid transferred to a cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com