High-strength anti-aging single-component modified sealant for bonding rubber and plastic composite materials and preparation method of high-strength anti-aging single-component modified sealant

A composite material and high-strength technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of low tear strength and elongation at break, difficult production control, and high viscosity of prepolymers. Improve the tear strength, reduce the difficulty of production control, and produce strong controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

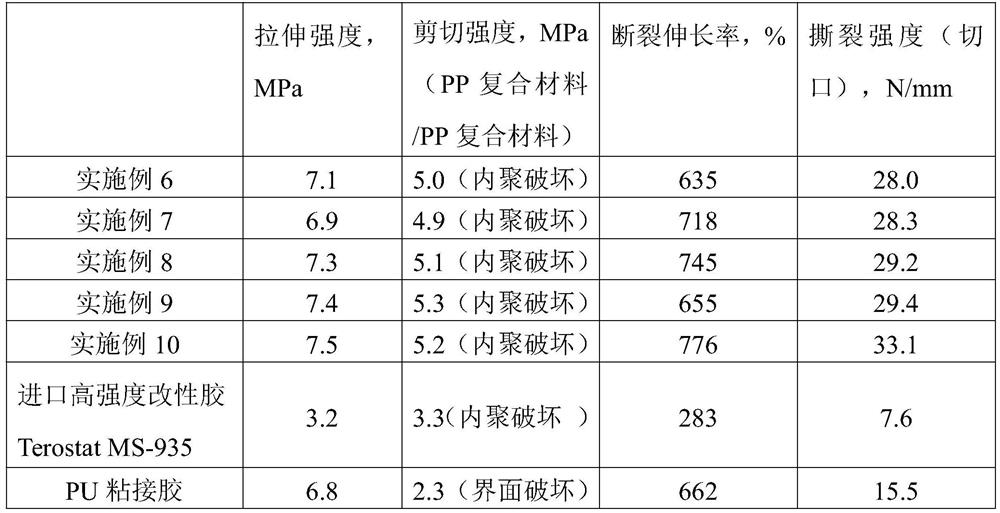

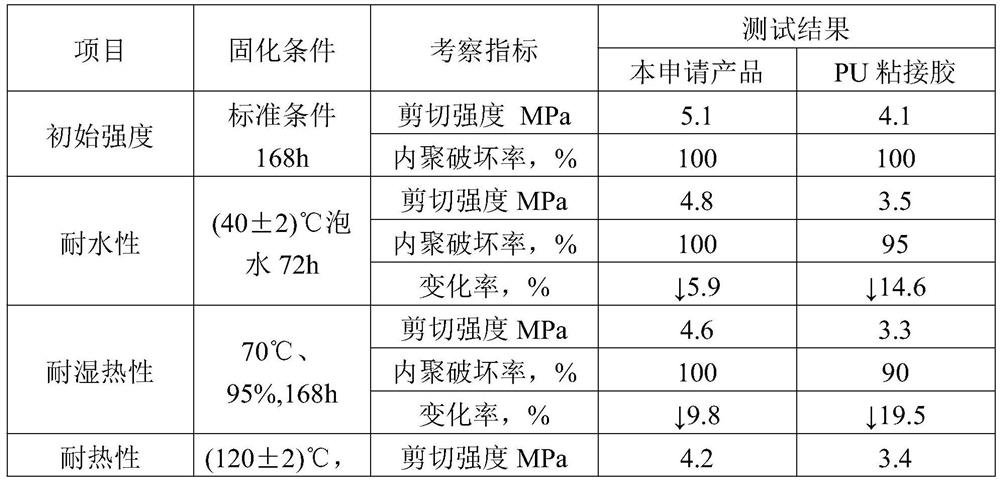

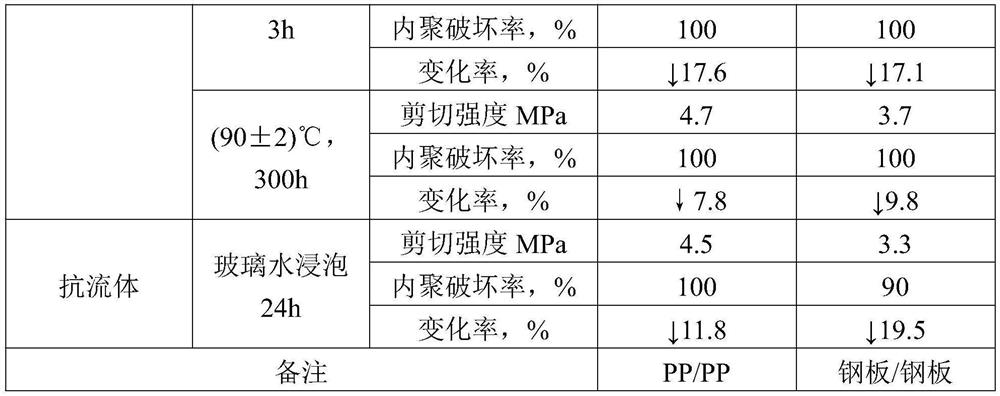

Examples

Embodiment 1

[0057] A high-strength aging-resistant single-component modified sealant for bonding rubber and plastic composite materials, consisting of the following raw materials: 40 kg of silane-terminated polyether polyurethane polymer, 10 kg of silane-modified acrylate polymer, the first plasticizer 15kg agent, 1kg water remover, 1kg adhesion promoter, 25kg filler, 0.5kg stabilizer and 0.05kg first catalyst;

[0058] The silane-terminated polyether polyurethane polymer is composed of the second polyether polyol, isocyanate, the second plasticizer, the terminal active hydrogen silane-terminated agent and the second catalyst according to the mass ratio of 40:15:20:2:0.01 composition;

[0059] The second polyether polyol is polyoxypropylene ether DL-3000D;

[0060] Described isocyanate is diphenylmethane diisocyanate;

[0061] The second plasticizer is chlorinated paraffin;

[0062] The terminal active hydrogen silane capping agent is 3-aminopropyltriethoxysilane;

[0063] The second ...

Embodiment 2

[0075] A high-strength aging-resistant single-component modified sealant for bonding rubber and plastic composite materials, consisting of the following raw materials: 30 kg of silane-terminated polyether polyurethane polymer, 5 kg of silane-modified acrylate polymer, the first plasticizer 30kg agent, 3kg water remover, 3kg adhesion promoter, 45kg filler, 1.5kg stabilizer and 0.5kg first catalyst;

[0076] The silane-terminated polyether polyurethane polymer is composed of the second polyether polyol, isocyanate, the second plasticizer, the terminal active hydrogen silane-terminated agent and the second catalyst according to the mass ratio of 60:25:35:3:0.2 composition;

[0077] The second polyether polyol is polyoxypropylene ether DL-4000D;;

[0078] Described isocyanate is toluene diisocyanate;

[0079] The second plasticizer is phenylmethylphenyl phosphate;

[0080] The terminal active hydrogen silane capping agent is 3-aminopropyltrimethoxysilane;

[0081] The second c...

Embodiment 3

[0093] A high-strength aging-resistant single-component modified sealant for bonding rubber and plastic composite materials, consisting of the following raw materials: 32 kg of silane-terminated polyether polyurethane polymer, 8 kg of silane-modified acrylate polymer, the first plasticizer 18kg agent, 1.5kg water remover, 1.5kg adhesion promoter, 30kg filler, 0.8kg stabilizer and 0.1kg first catalyst;

[0094] The silane-terminated polyether polyurethane polymer is composed of the second polyether polyol, isocyanate, the second plasticizer, the terminal active hydrogen silane-terminated agent and the second catalyst according to the mass ratio of 45:18:25:2.5:0.05 composition;

[0095] The second polyether polyol is polyoxypropylene ether DL-2000D;

[0096] The isocyanate is obtained by mixing isophorone diisocyanate and hexamethylene diisocyanate according to a mass ratio of 1:1;

[0097] The second plasticizer is obtained by mixing diphenyl-isooctyl phosphate and diisodecy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com