Multifunctional guided bone regeneration composite membrane as well as preparation method and application thereof

A guided bone regeneration and multifunctional technology, applied in the field of medical materials, can solve the problems of reducing the quality of life of patients and affecting the effect of periodontal tissue health and denture restoration, and achieve good cell compatibility, anti-bacterial adhesion, and antibacterial timeliness Promoted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

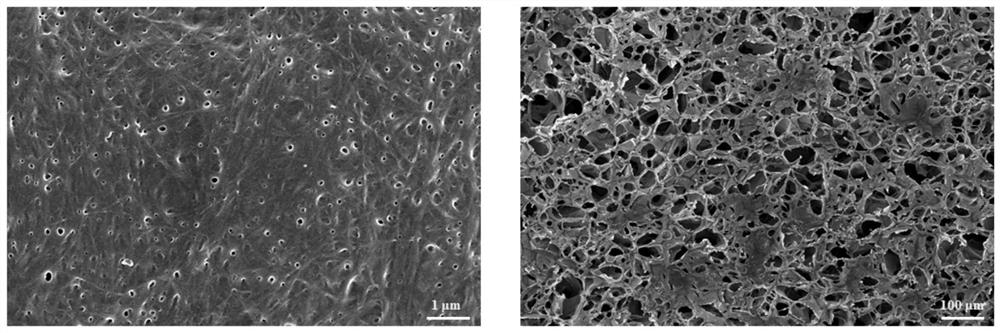

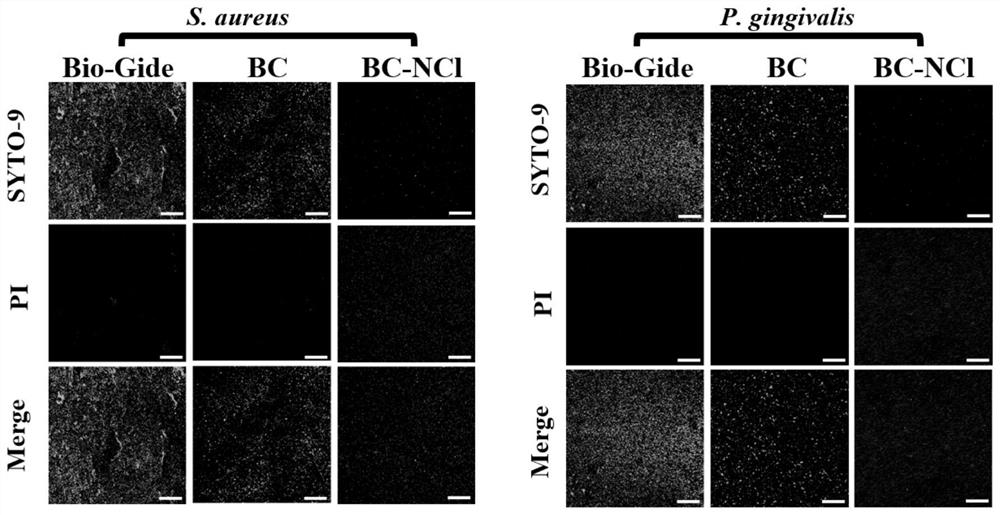

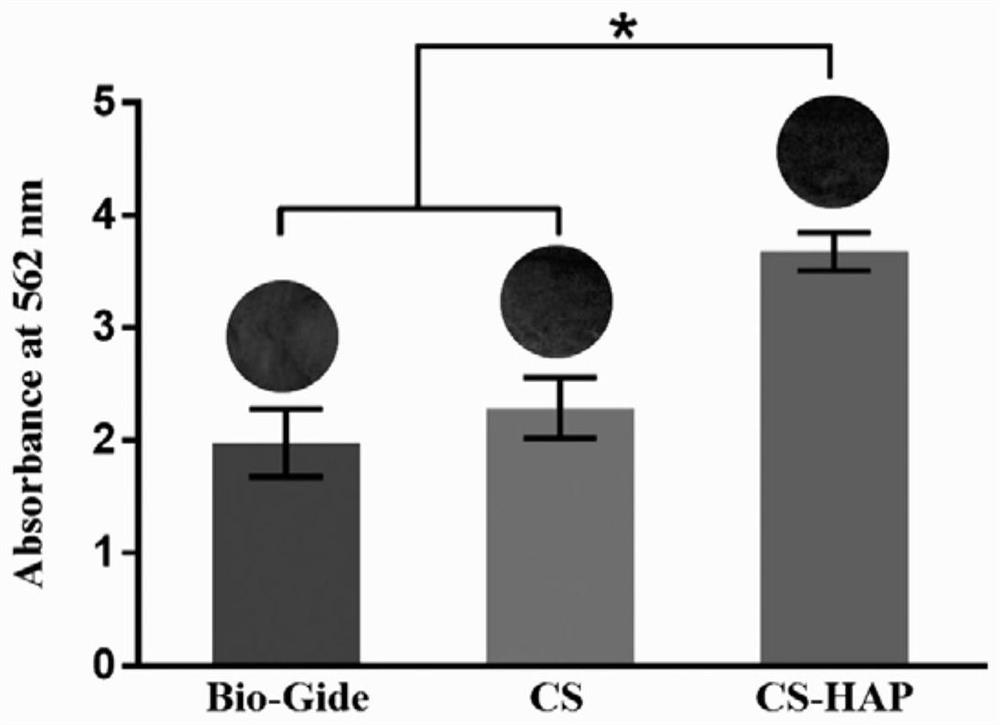

[0042] Embodiment 1, the preparation method of a kind of multifunctional guided bone regeneration composite film

[0043] A preparation method of a multifunctional guided bone regeneration composite film, comprising the following steps:

[0044] S1. Take a square bacterial cellulose film with a side length of 2 cm and a thickness of 1 mm, stir and wash it with double distilled water for 20 minutes, and dry it;

[0045] S2. Take 10 pieces of dried bacterial cellulose membranes and place them in 100mL 75% ethanol solution, pass nitrogen gas for 0.5h to remove oxygen, then add 3mL acetic acid and 1.5mL silane coupling agent KH570 and stir at room temperature for 0.5h, then place Heat and stir at 70°C for 3 hours, then rinse the product three times with absolute ethanol and once with pure water to obtain a double bond modified bacterial cellulose membrane;

[0046] S3. Place the double bond modified bacterial cellulose membrane in 80mL of pure water, pass nitrogen gas for 0.5h to...

Embodiment 2

[0049] Embodiment 2, the preparation method of a kind of multifunctional guided bone regeneration composite film

[0050] A preparation method of a multifunctional guided bone regeneration composite film, comprising the following steps:

[0051] S1. Take a square bacterial cellulose film with a side length of 2 cm and a thickness of 1 mm, stir and wash it with double distilled water for 20 minutes, and dry it;

[0052] S2. Take 10 pieces of dried bacterial cellulose membranes and place them in 100mL 75% ethanol solution, pass nitrogen gas for 0.5h to remove oxygen, then add 3mL acetic acid and 1.5mL silane coupling agent KH570 and stir at room temperature for 0.5h, then place Heat and stir at 70°C for 2.5 hours, then rinse the product three times with absolute ethanol and once with pure water to obtain a double bond modified bacterial cellulose membrane;

[0053] S3. Place the double bond modified bacterial cellulose membrane in 80mL of pure water, pass nitrogen gas for 0.5h ...

Embodiment 3

[0056] Embodiment 3, the preparation method of a kind of multifunctional guided bone regeneration composite film

[0057] A preparation method of a multifunctional guided bone regeneration composite film, comprising the following steps:

[0058] S1. Take a square bacterial cellulose film with a side length of 2 cm and a thickness of 1 mm, stir and wash it with double distilled water for 20 minutes, and dry it;

[0059] S2. Take 10 pieces of dried bacterial cellulose membranes and place them in 100mL75% ethanol solution, pass nitrogen gas for 0.5h to remove oxygen, then add 3mL acetic acid and 1.5mL silane coupling agent KH570 and stir at room temperature for 0.5h, then place at 75 Heating and stirring at ℃ for 3.5 hours, then washing the product three times with absolute ethanol and once with pure water to obtain a double bond modified bacterial cellulose membrane;

[0060] S3. Place the double bond modified bacterial cellulose membrane in 80mL of pure water, pass nitrogen ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com