Multifunctional dynamic bioreactor for multiphase osteochondral scaffold

A bioreactor and multifunctional technology, applied in the field of biomedical engineering, can solve the problems of lack of heterogeneous osteochondral scaffold reactors, etc., and achieve the effect of promoting function initialization, promoting formation, promoting growth and expression of some genes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

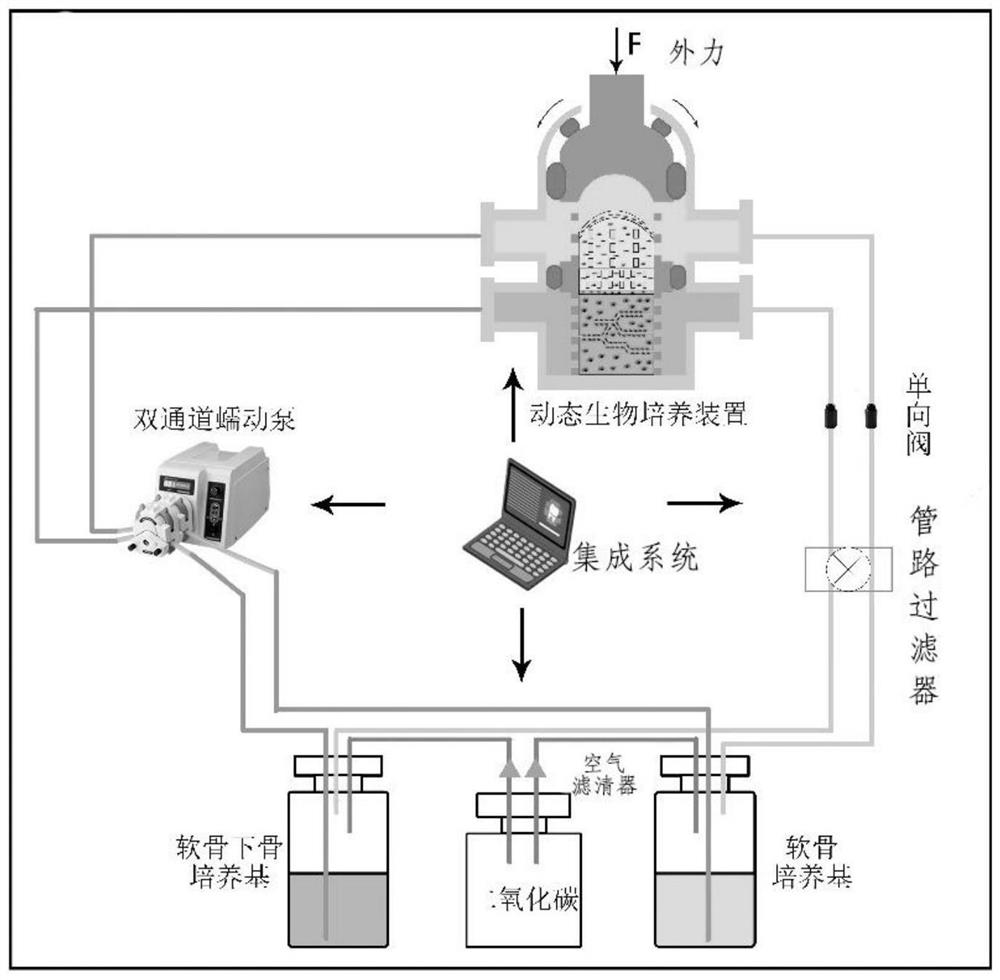

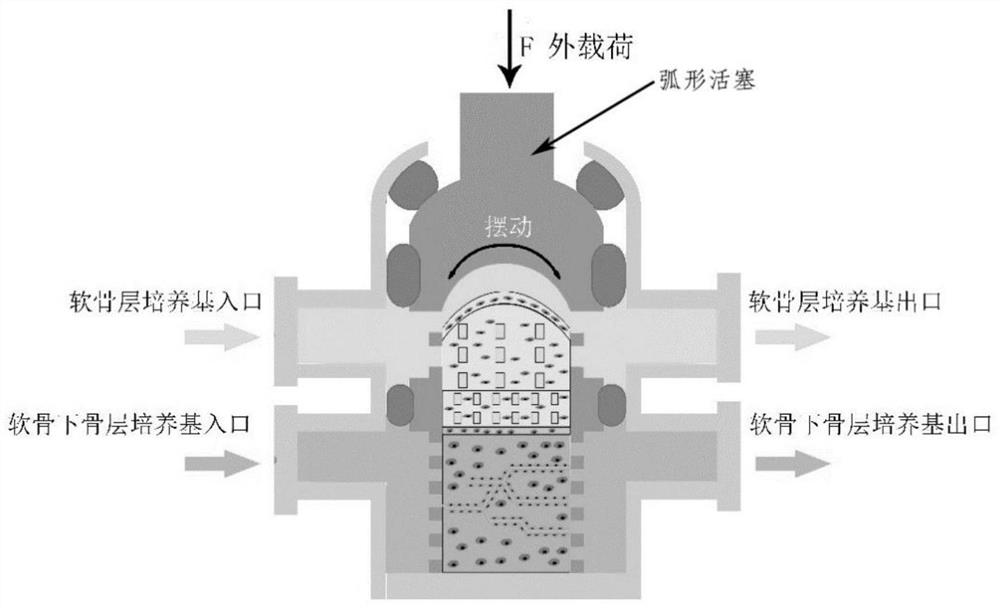

Method used

Image

Examples

Embodiment 1

[0052] The multiphase osteochondral scaffold was prepared by mold casting the biomaterial, which included chitosan 10% (w / v), silk fibroin 5% (w / v) and hydroxyapatite 10% (w / w); Solvent is PBS buffer solution;

[0053] The composition of the cartilage medium (upper layer) is 10% (v / v) fetal bovine serum, 100nmol / L dexamethasone, 35μg / mL vitamin C, 1mmol / L sodium pyruvate, 100mg / L penicillin, 100mg / L Streptomycin and 15mg / LBMP-7; the subchondral bone culture medium (lower layer) culture fluid composition is 10% (v / v) fetal calf serum, 100nmol / L dexamethasone, 10mmol / Lβ-sodium glycerophosphate, 0.2 mmol / L ascorbic acid, 100mg / L penicillin, 100mg / L streptomycin and 15mg / LBMP-2; all solvents are PBS buffer.

[0054] By adjusting the driving of the arc-shaped piston at the upper end of the dynamic biological culture device, the rotational shear force is loaded, and the liquid pressure sensors in the cartilage medium and subchondral bone medium are adjusted to load the multiphase o...

Embodiment 2

[0057] Cell-containing heterogeneous osteochondral scaffolds were prepared by bio-3D printing, and the solvent was PBS buffer; the material of the cartilage layer (upper layer) was 8% (w / v) chitosan+8% (w / v) collagen+5×10 6 cells / g bone marrow mesenchymal stem cells; the subchondral bone layer (lower layer) material is methacrylated gelatin (10% w / v), hyaluronic acid (10% w / v) and bone marrow mesenchymal stem cells ( 5×10 6 cells / g);

[0058] The composition of the culture solution (upper layer) of the cartilage medium is 15% (v / v) fetal bovine serum, 120nmol / L dexamethasone, 37.5μg / mL vitamin C, 2mmol / L sodium pyruvate, 100mg / L penicillin, 100mg / L streptomycin, 15mg / LTGF-β, 2ng / mL β-FGF, 6.25pg / ml bovine insulin, 6.25μg / mL transferrin, 15mg / LBMP-7, 1ng / mL cartilage angiogenesis inhibitor CAIF; cartilage The composition of the culture solution (lower layer) of the lower bone medium is 15% (v / v) fetal bovine serum, 120nmol / L dexamethasone, 15mmol / L beta-glycerophosphate sodium...

Embodiment 3

[0063] Bio-3D printing was used to prepare cell-containing heterogeneous osteochondral scaffolds, and the solvent was PBS buffer; the materials of the cartilage layer (upper layer) were: methacrylated gelatin (12% w / v), hydroxyapatite (5% w / w) and bone cells (5×10 6 cells / g); subchondral bone layer (lower layer) materials are: alginate (6% w / v), hyaluronic acid (6% w / v) and osteoblasts (5 × 10 6 cells / g);

[0064] The composition of the culture solution (upper layer) of the cartilage medium is 12% (v / v) fetal bovine serum, 120nmol / L dexamethasone, 37.5μg / mL vitamin C, 2mmol / L sodium pyruvate, 100mg / L penicillin, 100mg / L streptomycin, 15 mg / LTGF-β, 2 ng / mL β-FGF, 6.25 pg / ml bovine insulin, 6.25 μg / mL transferrin, 15 mg / LBMP-7, and 1 ng / mL cartilage angiogenesis inhibitor CAIF; cartilage The composition of the culture solution (lower layer) of the lower bone medium is 15% (v / v) fetal bovine serum, 120nmol / L dexamethasone, 15mmol / L beta-glycerophosphate sodium, 0.3mmol / L asco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com