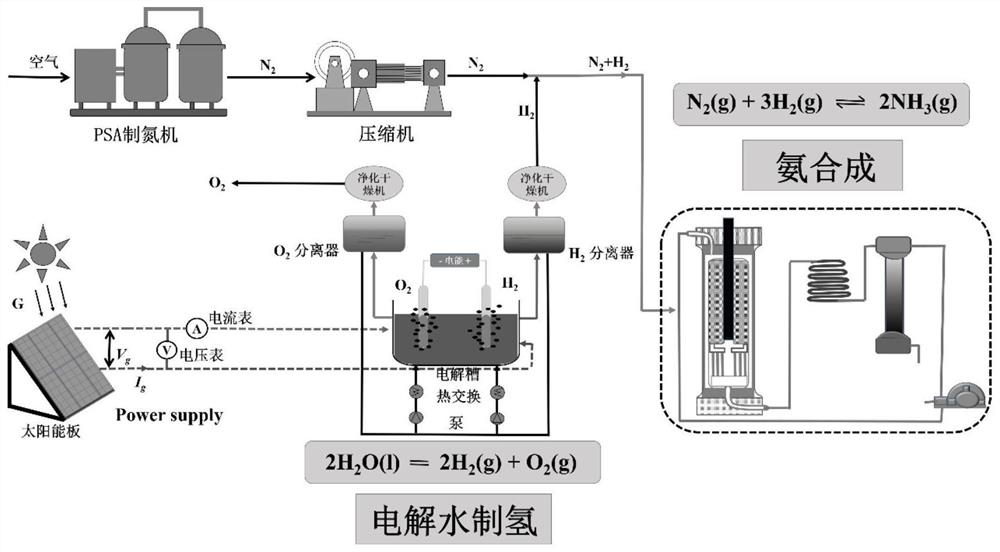

Preparation method of Ru-based catalyst with controllable particle size and application of Ru-based catalyst in'renewable energy electrolytic hydrogen production-ammonia synthesis'

A catalyst and ammonia synthesis technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problem of low hydrogen pressure, and achieve the effects of easy molding, high-efficiency ammonia synthesis, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] Disperse ruthenium trichloride (5.2mg, 0.025mmol), 1,10-phenanthroline (592mg, 3.0mmol), and melamine (900mg, 7.0mmol) in absolute ethanol (100mL), and after ultrasonic treatment for 10min, add Magnesium oxide (3.2 g, 0.08 mol) formed a homogeneous slurry; then sonicated for 10 min, then condensed and refluxed at 60 °C for 12 h, the solvent was removed by rotary evaporation at 60 °C, dried at 60 °C for 12 h and transferred to a tube furnace , under nitrogen atmosphere, at 2°C min -1 , heated up to 600°C, roasted for 2h, and after cooling down to room temperature, pour the obtained black powder into dilute nitric acid solution (1mol L -1 , 400mL), stirred at 80°C for 8h to remove magnesium oxide, then filtered and washed to neutral, then dried at 80°C for 12h to finally obtain Ru single-atom catalyst (marked as RuSAC), wherein the mass fraction of the active component was 0.39 wt%.

Embodiment 2

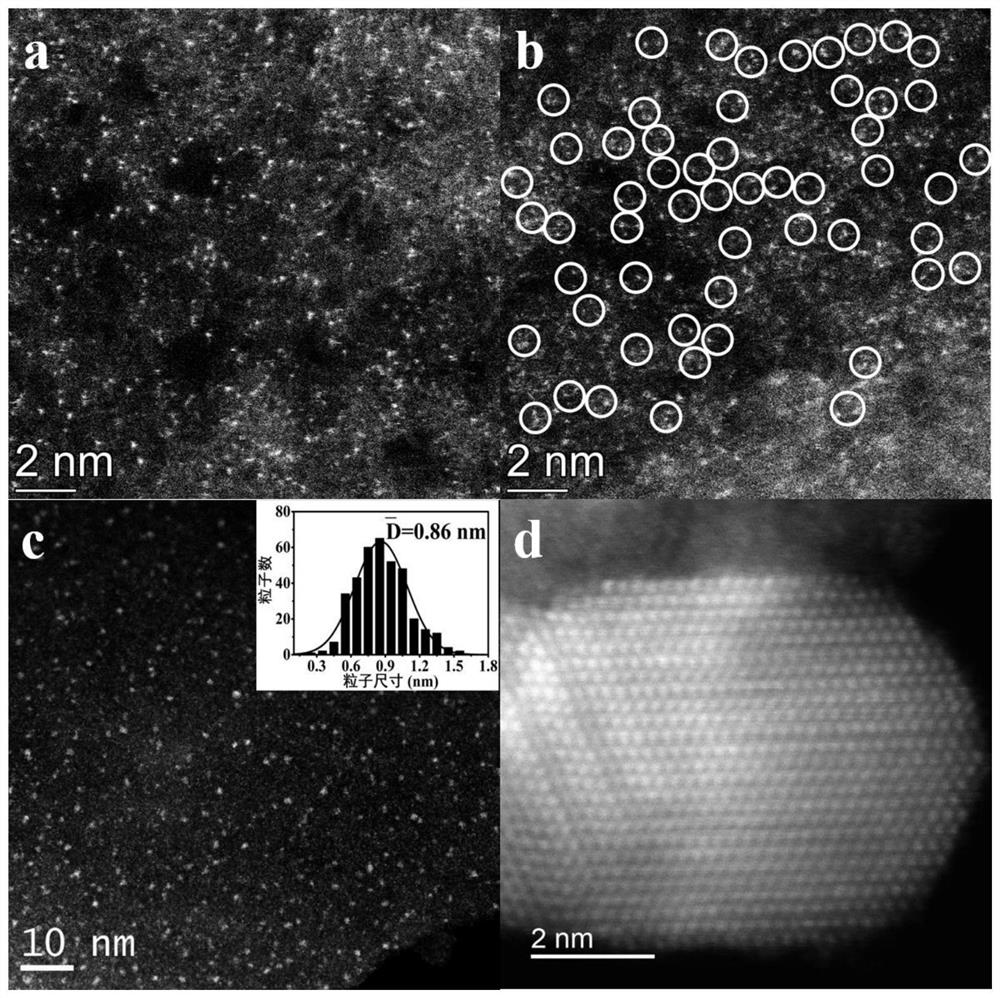

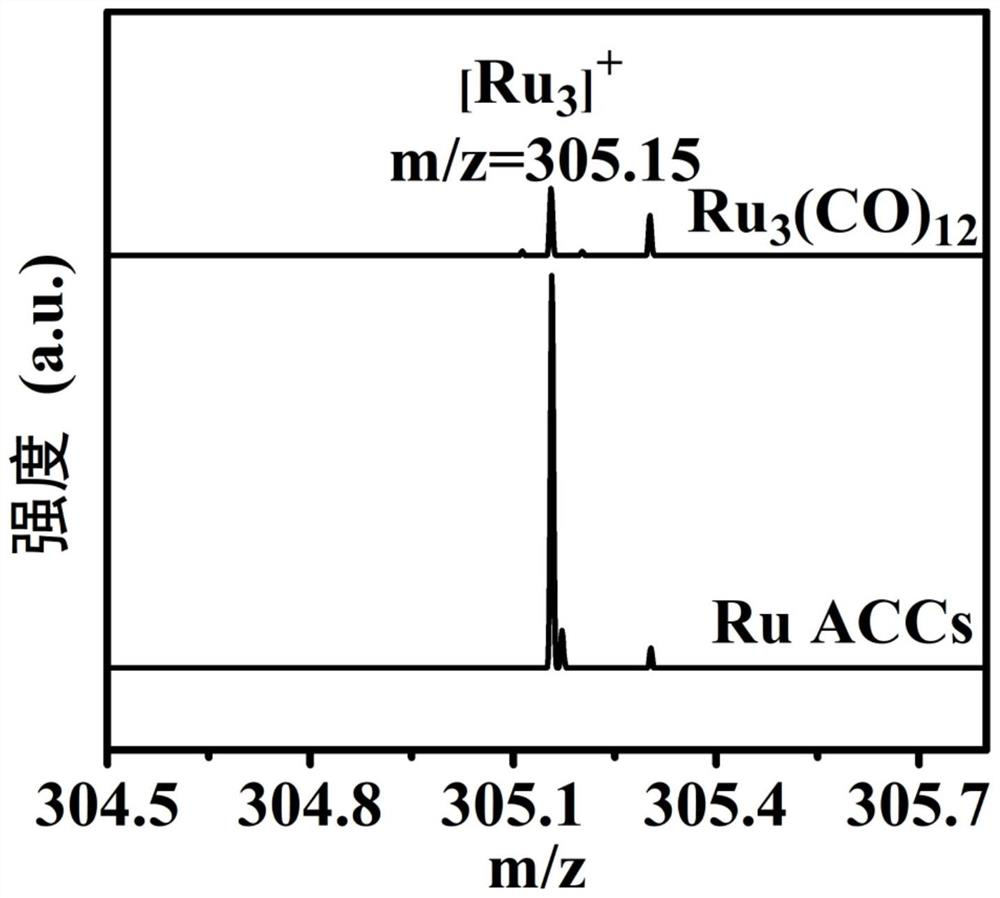

[0109] Triruthenium dodecacarbonyl (3.2mg, 0.005mmol), 1,10-phenanthroline (592mg, 3.0mmol) and melamine (900mg, 7.0mmol) were dispersed in absolute ethanol (100mL), and after ultrasonic treatment for 10min, Add magnesium oxide (6.4 g, 0.16 mol) to form a homogeneous slurry; then sonicate for 10 min, then reflux at 60 °C for 12 h, remove the solvent by rotary evaporation at 60 °C, and dry at 60 °C for 12 h before transferring to a tube furnace In nitrogen atmosphere, at 2°C min -1 , heated up to 600°C, roasted for 2h, and after cooling down to room temperature, pour the obtained black powder into dilute nitric acid solution (1mol L -1 , 400mL), stirred at 80°C for 8h to remove magnesium oxide, then filtered and washed to neutral, and dried at 80°C for 12h to finally obtain Ru cluster catalysts (marked as RuACCs), wherein the mass fraction of the active component was 0.40 wt%.

Embodiment 3

[0111] Triruthenium dodecacarbonyl (14.2mg, 0.022mmol) and 1,10-phenanthroline (298mg, 1.5mmol) were dispersed in a mixed solution of absolute ethanol and tetrahydrofuran (50mL, V / V=1:1), ultrasonic After processing for 10 min, magnesium oxide (6.4 g, 0.16 mol) was added to form a homogeneous slurry; then ultrasonic treatment was performed for 10 min, and then condensed and refluxed in a microwave single-mode reactor at 60 ° C for 12 h, the solvent was removed by rotary evaporation at 60 ° C, and the After drying at 60°C for 12h, transfer to a tube furnace, under nitrogen atmosphere, at 2°C min -1 , heated up to 600°C, roasted for 2h, and after cooling down to room temperature, pour the obtained black powder into dilute nitric acid solution (1mol L -1 , 200mL), stirred at 80°C for 8h to remove magnesium oxide, then filtered and washed to neutral, and dried at 80°C for 12h to finally obtain Ru subnano-cluster catalysts (marked as Ru SNCs), wherein the mass of the active compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com