Organic nickel ion battery electrolyte and organic nickel ion battery

An ion battery, organic nickel technology, applied in organic electrolytes, battery electrodes, nickel storage batteries, etc., can solve the problem that organic nickel ion batteries do not match organic electrolytes, etc., and achieve rich energy source storage systems, simple storage conditions, and simple preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

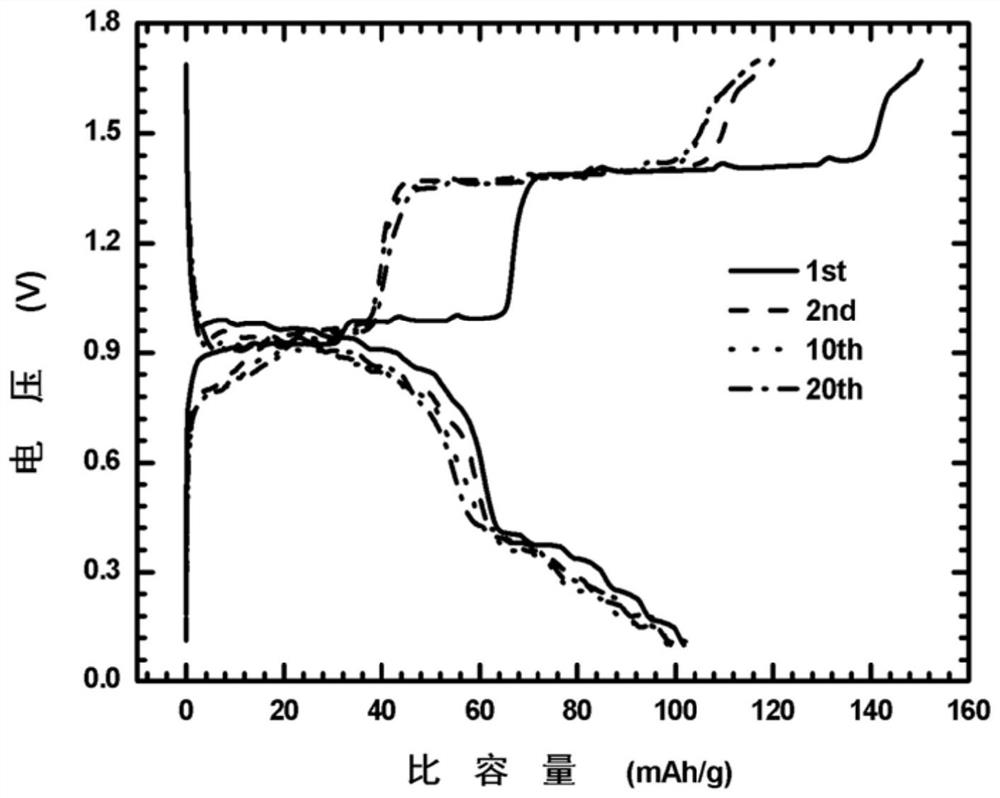

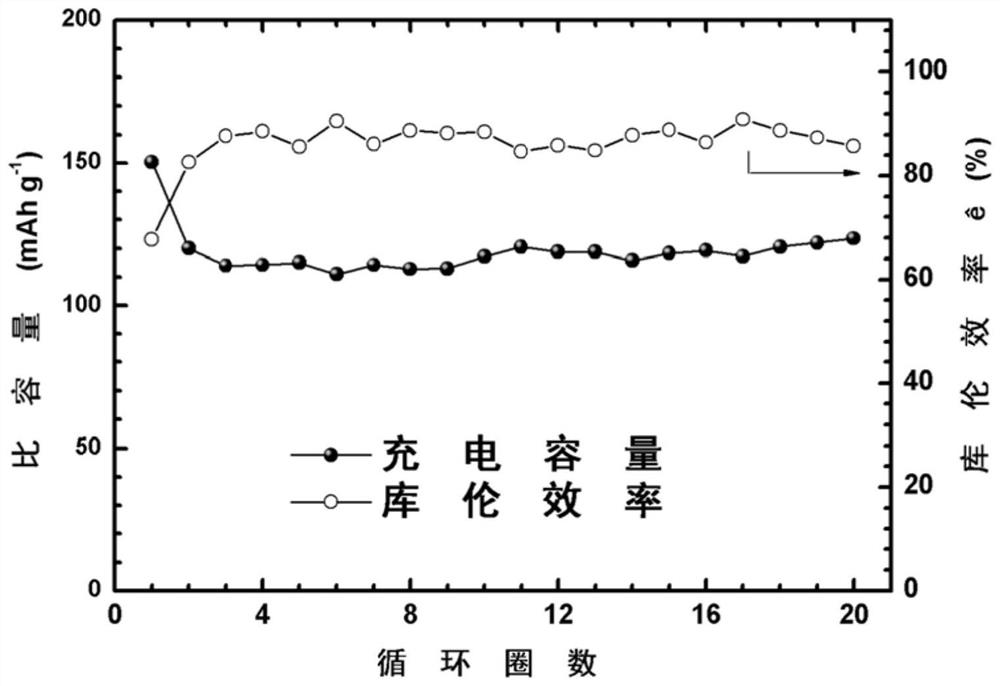

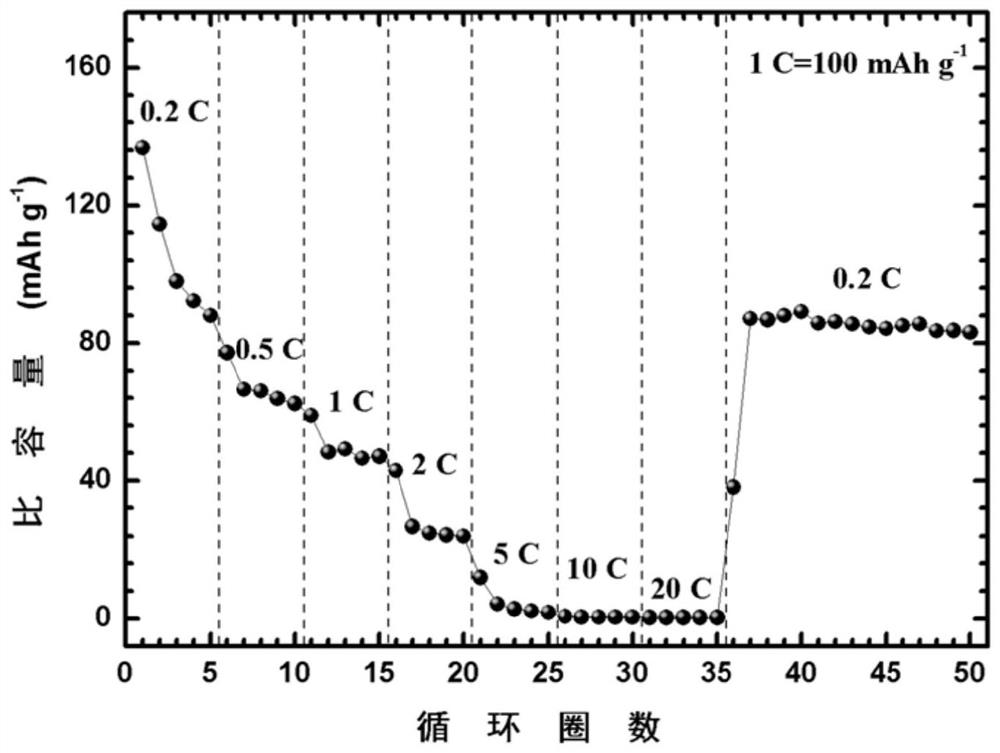

[0041] Mix lithium vanadium phosphate, acetylene black, and PVDF (polyvinylidene fluoride) in a mass ratio of 8:1:1 (total mass is 0.1000g), and add NMP (N-methylpyrrolidone) diluent with a rubber tip dropper (20 drops), after mixing evenly, spread it evenly on the titanium foil, and cut it into pole pieces with a diameter of 11 mm after drying. The nickel sheet was used as both the negative electrode and the reference electrode, the glass fiber was used as the separator, and the 1M nickel trifluoromethanesulfonate / ethylene glycol methyl ether solution was used as the electrolyte, which were assembled together with the prepared lithium vanadium phosphate electrode in an argon glove box. into a test battery. The battery can work stably in the voltage window of 0.1-1.7V, and its first two, tenth and twentieth charge-discharge curves are as follows figure 1 shown. At a current density of 10mA / g, the specific capacity of the first charge was 150.37mAh / g, and the specific capacit...

Embodiment 2

[0043] Mix lithium vanadium phosphate, Ketjen black, and PVDF (polyvinylidene fluoride) in a mass ratio of 7:2:1 (the total mass is 0.1000g), and add NMP (N-methylpyrrolidone) to dilute it with a plastic tip dropper. agent (20 drops), after mixing evenly, spread it evenly on the titanium foil, and cut it into pole pieces with a diameter of 11 mm after drying. The nickel foam was used as both the negative electrode and the reference electrode, the glass fiber was used as the separator, and the 0.8M nickel trifluoromethanesulfonate / ethylene glycol methyl ether solution was used as the electrolyte, together with the prepared lithium vanadium phosphate electrode sheet in an argon glove box. Assembled into test cells. The battery can work stably in the voltage window of 0.1-1.6V, and its first two, tenth and twentieth charge-discharge curves are as follows Figure 5 shown. At a current density of 10mA / g, the specific capacity of the first charge was 126.59mAh / g, and the specific ...

Embodiment 3

[0045] Mix lithium vanadium phosphate, acetylene black, and PVDF (polyvinylidene fluoride) according to the mass ratio of 7:2:1 (total mass is 0.1000g), and add NMP (N-methylpyrrolidone) diluent with a rubber tip dropper (20 drops), after mixing evenly, spread it evenly on the titanium foil, and cut it into pole pieces with a diameter of 11 mm after drying. The nickel foam was used as both the negative electrode and the reference electrode, the glass fiber was used as the separator, and the 1M nickel perchlorate / tetraethylene glycol dimethyl ether solution was used as the electrolyte, which were assembled together with the prepared lithium vanadium phosphate electrode in an argon glove box. into a test battery. The battery can work stably in the voltage window of 0.1-1.7V, and its first two, tenth and twentieth charge-discharge curves are as follows Figure 7 shown. At a current density of 100 mA / g, the specific capacity of the first charge was 136.01 mAh / g, and the specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com