Wet adhesive super-lubricating hydrogel coating and preparation method thereof

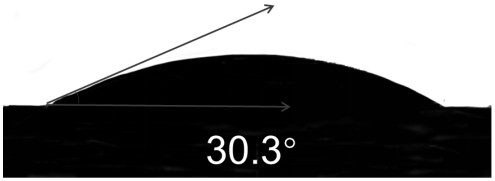

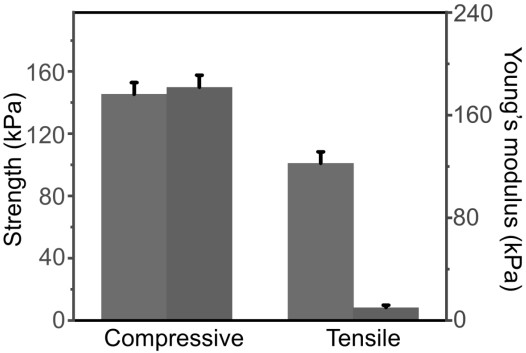

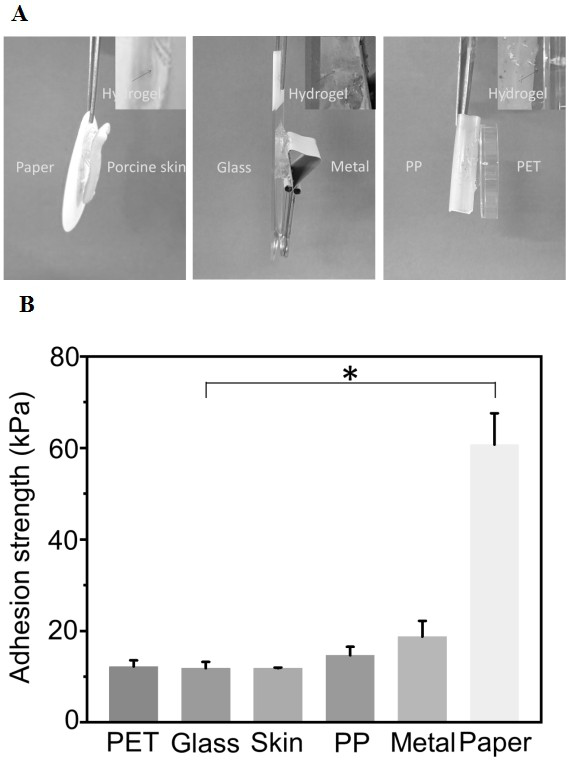

A hydrogel and super-lubricating technology, applied in coatings, pharmaceutical formulations, catheters, etc., can solve the problems of hydrogel dehydration, uneven coating, insufficient adhesion, etc., to achieve strong adhesion, mechanical High intensity, pain relieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 5% ( W / V) Acrylamide monomer, 2% ( W / V) The sodium alginate powder was dissolved in deionized water, and the solution was evenly stirred for 18 h to mix completely to obtain solution A;

[0045] Add 0.01% ( W / V) cross-linking agent N,N' − Methylenebisacrylamide, 0.05% ( W / V) The cross-linking accelerator tetramethylethylenediamine, 0.1% ( W / V) The hydrophilic photoinitiator ammonium persulfate and 0.2% ( W / V) The ionic crosslinking agent calcium sulfate dihydrate, the stirring time is 6 h, mix well to obtain solution B;

[0046] Add the binder tannic acid to the solution B, stir well until the mixture is uniform, and then the pregel solution C can be obtained; the mass ratio of the added tannic acid to the hydrogel monomer contained in the solution B is 0.01 :100;

[0047] Immerse the catheter in the pregel solution C, take it out after 2 seconds, put it under ultraviolet light for 0.5 h, and then let it stand at room temperature for 12 h to complete the p...

Embodiment 2

[0049] 15% ( W / V ) of acrylamide monomer, 2% ( W / V ) Sodium alginate powder was dissolved in deionized water, and the solution was evenly stirred for 18 h to mix completely to obtain solution A;

[0050] Add 0.05% ( W / V ) of the cross-linking agent N,N' − Methylenebisacrylamide, 0.32% ( W / V ) of the cross-linking accelerator tetramethylethylenediamine, 0.13% ( W / V ) of the hydrophilic photoinitiator ammonium persulfate and 0.25% ( W / V ) ionic cross-linking agent calcium sulfate dihydrate, the stirring time is 6 h, mix well to obtain solution B;

[0051] Add the binder chitosan to the solution B, stir well until the mixture is uniform, and then the pregel solution C can be obtained; the mass ratio of the added chitosan to the hydrogel monomer contained in the solution B is 0.01 :100;

[0052] Immerse the catheter in the pregel solution C, take it out after 2 seconds, put it under ultraviolet light for 0.5 h, and then let it stand at room temperature for 12 h to co...

Embodiment 3

[0054] 30% ( W / V ) of acrylic monomer, 5% ( W / V ) Sodium alginate powder was dissolved in deionized water, and the solution was evenly stirred for 18 h to mix completely to obtain solution A;

[0055] Add 0.1% ( W / V ) of the cross-linking agent N,N' − Methylenebisacrylamide, 0.50% ( W / V ) of the cross-linking accelerator tetramethylethylenediamine, 0.15% ( W / V ) of the hydrophilic photoinitiator ammonium persulfate and 0.3% ( W / V ) ionic crosslinking agent calcium sulfate dihydrate, the stirring time is 24 h, mix well to obtain solution B;

[0056] Add the adhesive dopamine to the solution B, stir well until the mixture is uniform, and then the pre-gel solution C can be obtained; the mass ratio of the added dopamine to the hydrogel monomer contained in the solution B is 0.01:100;

[0057] Immerse the catheter in the pregel solution C, take it out after 2s, place it under ultraviolet light for 0.5 h, and then let it stand for 12 h to complete the polymerization. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com