Carbon nanotube-carbon nanosheet-germanium composite negative electrode material and preparation method and application thereof

A carbon nanosheet and carbon nanotube technology, which is applied in the field of carbon nanotube-carbon nanosheet-germanium composite negative electrode material and its preparation field, can solve the problems of poor electrochemical activity and large volume expansion effect of germanium negative electrode, and achieves low price. , easy to obtain, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention proposes a method for preparing a carbon nanotube-carbon nanosheet-germanium composite negative electrode material, comprising the following steps:

[0021] S1: Ball mill the sodium salt of an organic acid, heat-treat in an inert atmosphere, filter, wash, and dry after cooling to obtain a three-dimensional porous carbon nanosheet powder.

[0022] Preferably, the sodium salt of an organic acid is at least one of sodium citrate, sodium ascorbate, sodium succinate and sodium gluconate; the selected sodium salt of an organic acid can be cracked into sodium carbonate crystals and include For the carbon coating layer, the sodium carbonate crystals are washed with water to obtain a three-dimensional porous carbon nanosheet structure.

[0023] The inert atmosphere is Ar gas, N 2 Gas, Ar / H 2 One of the gas mixtures. Cleavage of organic acid sodium salts to carbon under an inert atmosphere.

[0024] Preferably, the speed of the ball mill is 100-500r / min,...

Embodiment 1

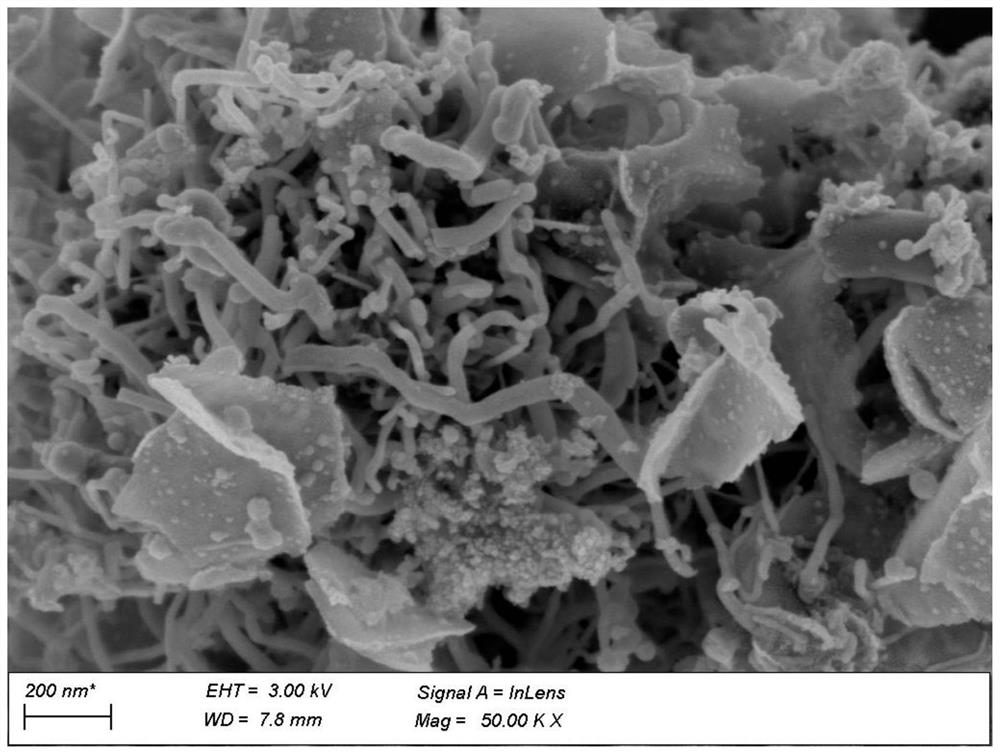

[0043] This embodiment provides a carbon nanotube-carbon nanosheet-germanium composite negative electrode material, which is composed of nano-germanium, carbon nano-sheets and carbon nanotubes, and is a three-dimensional network porous structure; both nano-germanium and carbon nanotubes are grown on carbon In the three-dimensional pore structure of nanosheets. The particle size of the nano-germanium is 30-100 nm, the diameter of the carbon nano-tube is 10-50 nm, and the thickness of the carbon nano-sheet is 5-10 nm.

[0044] The present invention also proposes a method for preparing the above-mentioned carbon nanotube-carbon nanosheet-germanium composite negative electrode material, comprising the following steps:

[0045] (1) Put 60g of sodium citrate into a planetary ball mill at 350r / min for 3h, place it in a tube furnace and heat it up to 700°C for 2h under a high-purity Ar atmosphere. After cooling, filter, wash, and dry to obtain black three-dimensional Porous carbon na...

Embodiment 2

[0053] This embodiment provides a carbon nanotube-carbon nanosheet-germanium composite negative electrode material, which is composed of nano-germanium, carbon nano-sheets and carbon nanotubes, and is a three-dimensional network porous structure; both nano-germanium and carbon nanotubes are grown on carbon In the three-dimensional pore structure of nanosheets. The diameter of the nano-germanium is 30-100nm, the diameter of the carbon nanotube is 10-100nm, and the thickness of the carbon nano-sheet is 5-20nm.

[0054] The present invention also proposes a method for preparing the above-mentioned carbon nanotube-carbon nanosheet-germanium composite negative electrode material, comprising the following steps:

[0055] (1) Put 60g of potassium citrate into a planetary ball mill at 350r / min for 3h, put it in a tube furnace and raise the temperature to 800°C for 2h under a high-purity Ar atmosphere, then filter, wash, and dry after cooling to obtain a black three-dimensional Porous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com