Mesoporous silicon loaded with hyaluronic acid and resveratrol as well as preparation method and application thereof

A technology of resveratrol and hyaluronic acid, applied in the field of biomedical engineering, can solve problems such as poor spreadability, poor adhesion, and limited application, and achieve enhanced moisturizing and anti-oxidation effects and biocompatibility Reinforcement, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

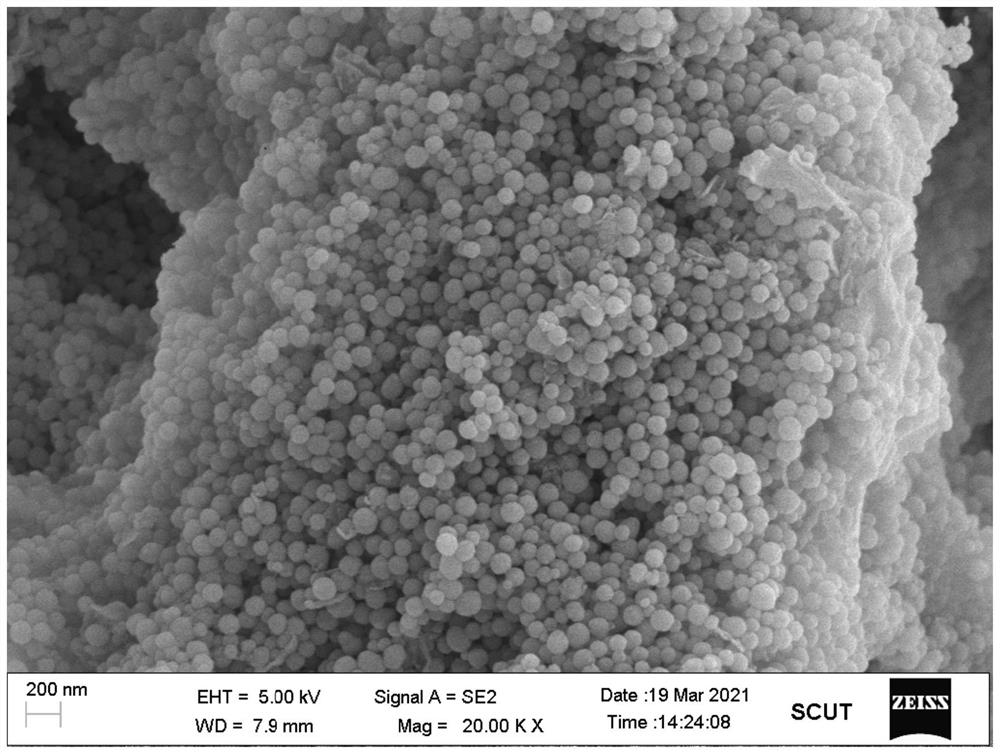

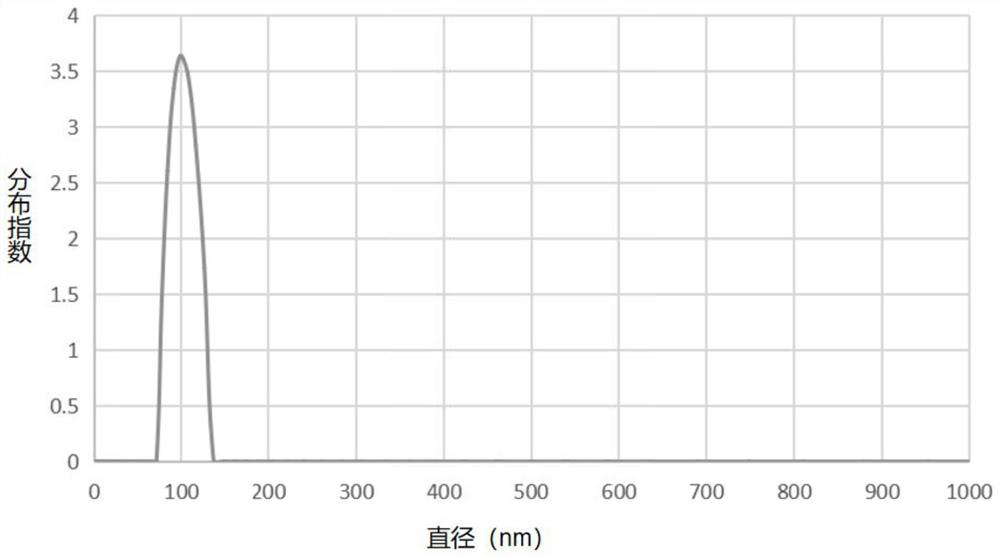

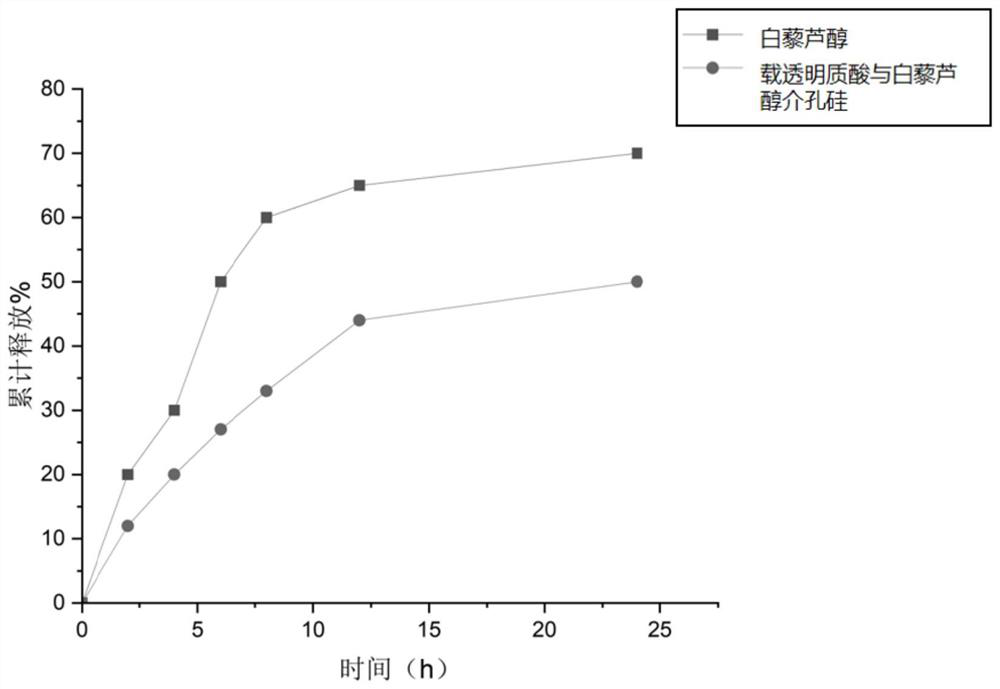

[0036] (1) The preparation method of mesoporous silicon: mix 1mL of cetyltrimethylammonium chloride (CTAC) aqueous solution (the concentration of CTAC aqueous solution is 25wt%, 0.756mol / L) with 120mL of water, 0.876mL of 2M NaOH Stir the aqueous solution at 80°C for 1 hour, then add 1 mL of tetraethyl orthosilicate (98% TEOS solution, 4.388 mol / L), react for 2 hours, then centrifuge, wash twice with ethanol, wash twice with water, and place in vacuum Dry in a drying oven, transfer to a muffle furnace after drying, and dry at 600°C for 5 hours to obtain mesoporous silicon;

[0037] (2) Amination modification of mesoporous silicon: add 0.2 g of mesoporous silicon to 20 mL of isopropanol and sonicate for 20 minutes, replenish isopropanol to 100 mL, add 2 mL of 3-aminopropyltriethoxysilane (4.2 mol / L) , stirred at 80°C for 24 hours, centrifuged, washed several times with isopropanol, and freeze-dried to obtain aminated mesoporous silicon;

[0038] (3) Hyaluronic acid modificatio...

Embodiment 2

[0043] Stir 1 mL of cetyltrimethylammonium chloride (CTAC) aqueous solution (concentration of CTAC aqueous solution is 25 wt%, 0.756 mol / L) with 120 mL of water and 0.784 mL of 2.5 M NaOH aqueous solution at 85° C. for 0.5 h, Then add 1.14mL of tetraethyl orthosilicate (98% TEOS solution, 4.388mol / L), react for 1.5 hours, then centrifuge, wash with ethanol twice, wash twice with water, then place in a vacuum oven to dry until the drying is complete Then transfer to a muffle furnace and dry at 550°C for 5 hours to obtain mesoporous silicon.

[0044] (2) Amination modification of mesoporous silicon: Add 0.37 g of mesoporous silicon to 25 mL of isopropanol and sonicate for 30 minutes, replenish isopropanol to 275 mL, add 2 mL of 3-aminopropyltriethoxysilane (4.2 mol / L ), stirred at 75° C. for 28 h, centrifuged, washed several times with isopropanol, and freeze-dried to obtain aminated mesoporous silicon.

[0045] (3) Hyaluronic acid modification of mesoporous silicon: add 0.12 g...

Embodiment 3

[0049] Stir 1mL of cetyltrimethylammonium chloride (CTAC) aqueous solution (the concentration of CTAC aqueous solution is 25wt%, 0.756mol / L) with 120mL of water and 1mL of 1.5M ammonia water at 75°C for 1.5h, then add 0.85mL tetraethyl orthosilicate (98% TEOS solution, 4.388mol / L), reacted for 2.5 hours, centrifuged, washed twice with ethanol, washed twice with water, then dried in a vacuum oven, transferred after drying Dry in a muffle furnace at 575°C for 5 hours to obtain mesoporous silicon.

[0050] (2) Amination modification of mesoporous silicon: Add 0.136g of mesoporous silicon to 27mL isopropanol and sonicate for 10min, replenish isopropanol to 95mL, add 2mL 3-aminopropyltriethoxysilane (4.2mol / L ), stirred at 77.5° C. for 20 h, centrifuged, washed several times with isopropanol, and freeze-dried to obtain aminated mesoporous silicon.

[0051] (3) Hyaluronic acid modification of mesoporous silicon: add 0.12 g of sodium hyaluronate into a Tris-HCl buffer solution with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com