Application of magnetic composite material in removal of plastic fragments

A technology of magnetic composite materials and plastic fragments, applied in the field of adsorption, can solve the problems of unsuitable removal and low adsorption capacity, and achieve the effect of short response time and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Synthesis of Magnetic ANM (Artificial Melanin)

[0063] Overall, magnetic ANMs were synthesized as follows: Fe(II) and Fe(III) chlorides were dissolved in alkaline medium ammonium hydroxide (NH 3 ·H 2 O) Co-precipitation to synthesize magnetic Fe 3 o 4 , and then the magnetic Fe 3 o 4 Mixed with raw materials for the synthesis of polydopamine to obtain polydopamine-coated Fe 3 o 4 (i.e. a magnetic ANM is obtained).

[0064] Specifically, a): 10 mL containing Fe(II) and Fe(III) chloride (Fe II / Fe III Molar ratio = 1:4) of deionized water and ethanol (volume 1:1) and 0.2mL NH 3 ·H 2 O was placed in a 50 mL round bottom flask under nitrogen and stirred at 25°C for 1 hour. The product was washed 3 times with deionized water and ethanol and removed by an external magnet to give Fe 3 o 4 Magnetic nanoparticles; b) Then, under stirring at 25°C, 2 mg of lysine was completely dissolved in 20 mL of deionized water and ethanol (1:1 volume ratio); 5 mL of DA (1 mg mL ...

Embodiment 1-1 to 1-9

[0066] The only difference between these examples and Example 1 is that the same mass of ammonia water, arginine, sodium hydroxide, potassium hydroxide, phenethylamine, naphthylethylamine, n-propylamine, 1,5-pentanediamine and ethylamine were used respectively. Diamine was used as an initiator instead of lysine in Example 1, and finally a magnetic ANM was also synthesized.

[0067] The results of the magnetic ANMs synthesized in Example 1 and Examples 1-1 to 1-9 are shown in Table 1 below.

[0068] Table 1 Magnetic ANM prepared by different initiators

[0069]

Embodiment 2

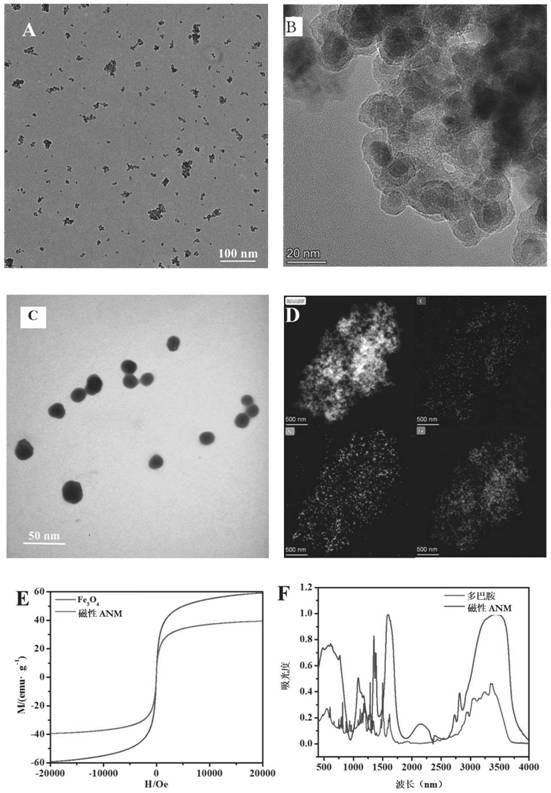

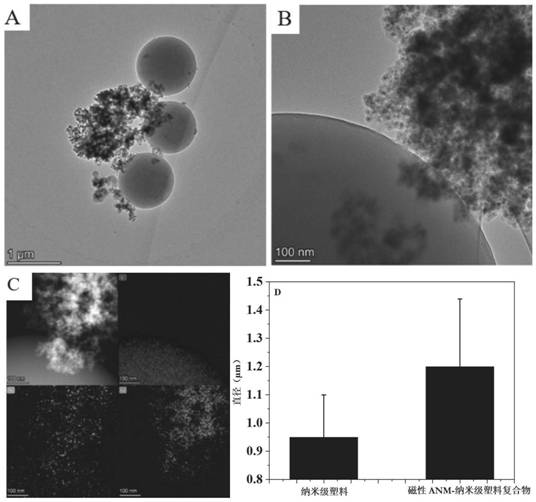

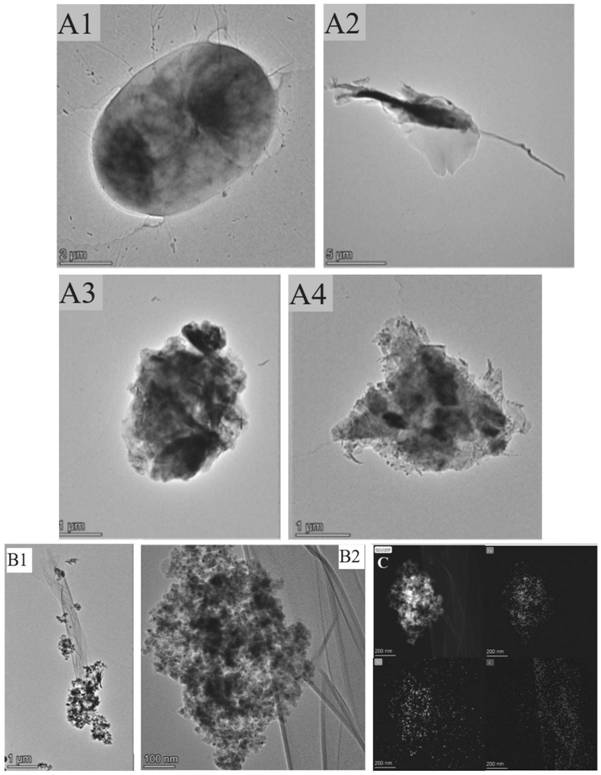

[0071] Characterization of Magnetic ANM (Artificial Melanin)

[0072] The size of the magnetic ANM was determined by a Nanolink S900 instrument by dynamic light scattering (DLS) (Zhenli, China). The morphology of the magnetic ANMs was characterized by transmission electron microscopy (TEM) (JEOL JEM-2100F, Japan). Energy-dispersive X-ray spectroscopy (EDS) analysis was performed to identify the elements present in the magnetic ANM nanocomposites. The chemical structure of the magnetic ANM was analyzed by Fourier transform infrared spectroscopy (FTIR) (Thermo Scientific Nicolet TM 6700 FT-IR Spectrometer, USA) for characterization. A vibrating sample magnetometer (VSM) is a common tool for measuring the magnetic properties of superparamagnetic materials.

[0073] TEM results showed that Fe 3 o 4 NP nanospheres ( figure 1 A). In this application, Fe 3 o 4 NP is used as the core and ANM as the shell pair Fe 3 o 4 NP for coating (see figure 1 B), the size of the mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization value | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com