Preparation method of acid-sensitive photoresist resin monomer

A technology of resin monomer and photoresist, applied in the field of photoresist, can solve the problem of low purity of the preparation method, and achieve the effects of high purity, high yield and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

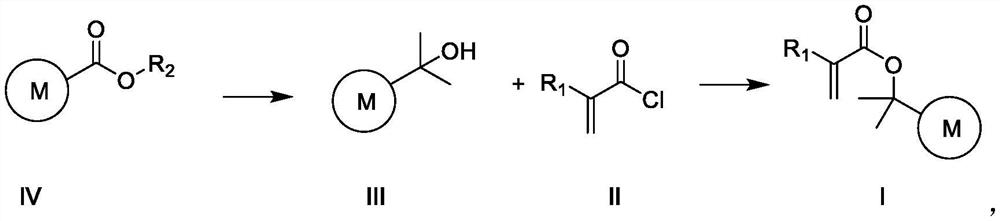

Method used

Image

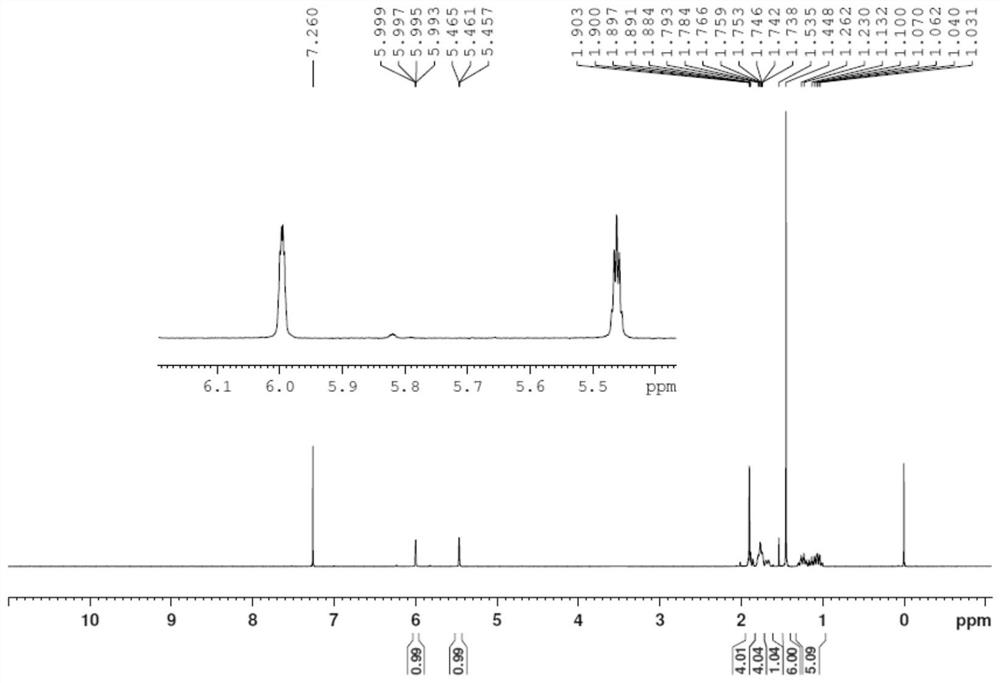

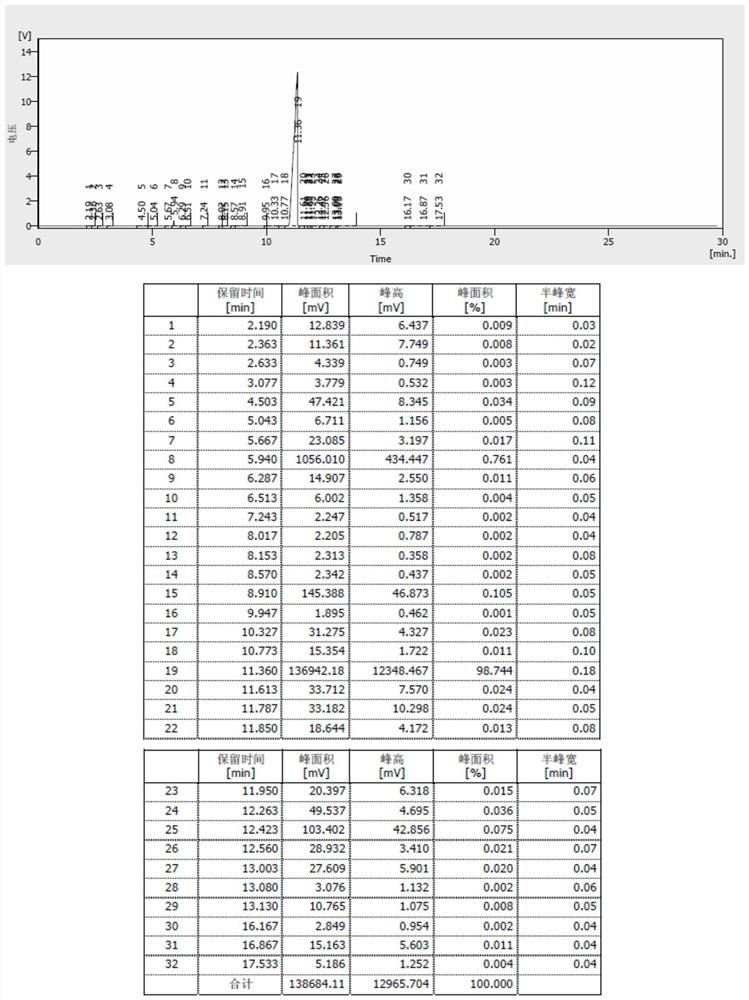

Examples

Embodiment 1

1,

[0076]

[0077] Add methanol (720 g) and cyclohexyl formic acid (150 g, 1.17 mol) to a four-necked reaction flask, add 9 g of concentrated sulfuric acid (6 wt % of cyclohexyl formic acid) with a mass concentration of 98% under stirring, and heat to reflux for 2 h (oil bath temperature 90°C), GC traced until the raw materials basically disappeared, and after rotary distillation of methanol until there was no liquid drop (water bath temperature 40°C), oil pump simple distillation (distillation temperature 25~30°C, oil bath 50°C) obtained 133g of the product, molar yield 80%, 98.8% pure.

2,

[0078]

[0079] Tetrahydrofuran (450g) was added into the four-necked bottle, the stopper was sealed with parafilm, and weighed. Cool to -20°C with dry ice ethanol, start to pass through methyl bromide (record the weight of the steel cylinder), pay attention to observe the bubbler, after the ventilation is completed, weigh the weight of the four-necked bottle again, and confirm ...

Embodiment 2

1,

[0085]

[0086] Add methanol (720g) and cyclohexyl formic acid (150g, 1.17mol) to a four-necked reaction flask, add 15 g of concentrated sulfuric acid (10 wt% of cyclohexyl formic acid) with a mass concentration of 98% under stirring, and heat to reflux for 1.5 h (oil bath temperature 95°C), GC traced until the raw materials basically disappeared, and after rotary distillation of methanol until there was no liquid drop (water bath temperature 40°C), oil pump simple distillation (distillation temperature 25~30°C, oil bath 50°C) obtained 136g of product, molar yield The yield is 83%, and the purity is 98.6%.

2,

[0087]

[0088] Tetrahydrofuran (450g) was added into the four-necked bottle, the stopper was sealed with parafilm, and weighed. Cool to -10°C with dry ice ethanol, start to ventilate methyl chloride (record the weight of the steel cylinder), pay attention to observe the bubbler, after the ventilating, weigh the weight of the four-neck bottle again, confirm...

Embodiment 3

1,

[0093]

[0094] Methanol (720g) and cyclohexyl formic acid (150g, 1.17mol) were added to a four-necked reaction flask, and under stirring, 7.5 g of concentrated sulfuric acid (5 wt% of cyclohexyl formic acid) with a mass concentration of 98% was added, and the reaction was heated under reflux for 2.5h ( oil bath temperature 85°C), GC traced until the raw materials basically disappeared, and after rotary distilling methanol until there was no liquid drop (water bath temperature 40°C), oil pump simple distillation (distillation 25~30°C, oil bath 50°C) obtained 130g of product, molar yield Yield 78.1%, purity 98.9%.

2,

[0095]

[0096] Tetrahydrofuran (450g) was added into the four-necked bottle, the stopper was sealed with parafilm, and weighed. Cool to -20°C with dry ice ethanol, start to pass through methyl bromide (record the weight of the steel cylinder), pay attention to observe the bubbler, after the ventilation is completed, weigh the weight of the four-neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com