Mask-free patterned film as well as preparation method and application thereof

A patterned thin film, no mask technology, applied in metal material coating process, vacuum evaporation coating, coating, etc. Problems such as low utilization rate, to achieve the effect of small distance, short coating distance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

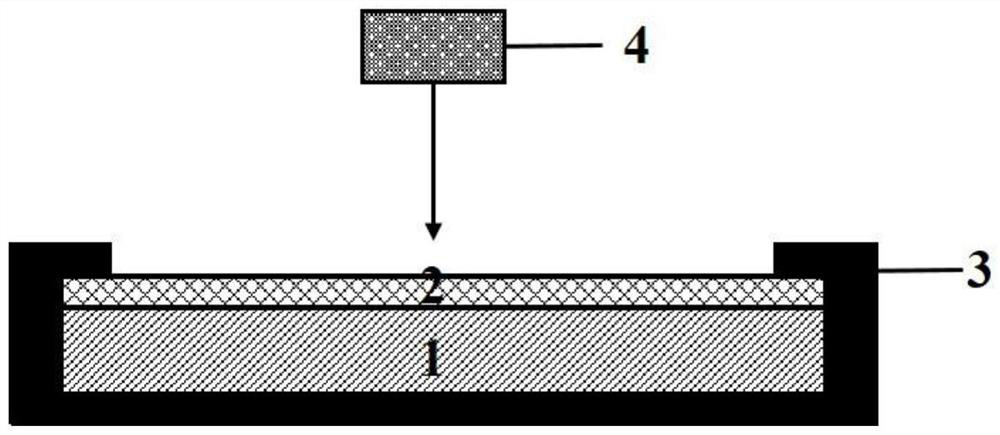

[0097] Such as figure 1 with figure 2 As shown, a method for preparing a patterned film by laser direct writing on a small-sized substrate comprises the following steps:

[0098] 1) Clean the substrate to be plated. The substrate to be plated is a quartz plate. The substrate to be plated is sequentially immersed in acetone, ethanol, and DI water for ultrasonic cleaning for 5 minutes, and then rinsed with DI water. After cleaning, the substrate is dried.

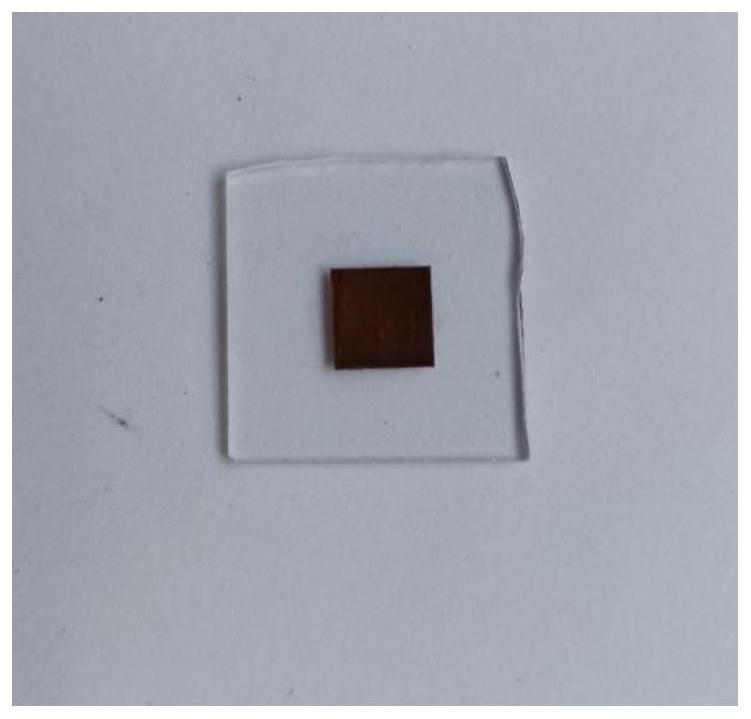

[0099] 2) Fix the substrate to be plated and the coating material. The coating material is a copper sheet; the substrate to be plated is placed on the bottom, and the coating material is placed on the top and fixed with a fixture.

[0100] 3) Pattern design and parameter setting. Copper sheets are processed by laser scanning set by software installed on a computer. Set a square pattern with a size of 2×2cm on the software, and process it with a laser with a scanning speed of 10mm / s and a power of 1.8W.

[0101] 4) Lase...

Embodiment 2

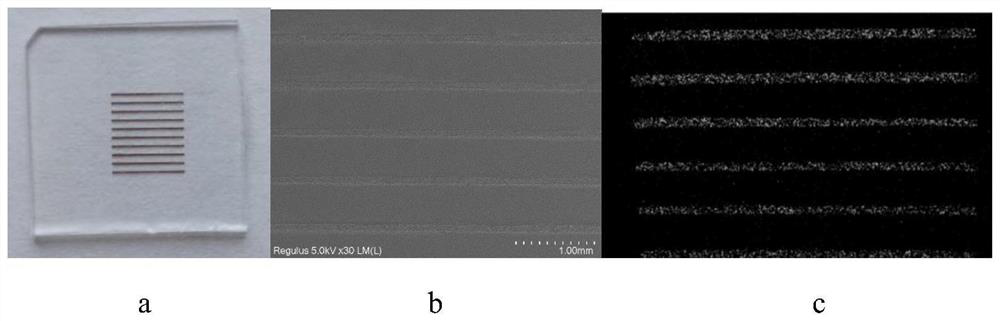

[0103] Such as image 3 As shown, a method suitable for preparing a patterned film by laser direct writing on a large-scale substrate differs from Example 1 in that:

[0104] Step 1) Clean the substrate to be plated. The substrate to be plated is glass. Rinse the substrate to be plated directly with a DI water gun. After cleaning, dry the substrate to be plated with a nitrogen gun.

[0105] Step 2) The substrate to be plated and the coating material are fixed. The coating material is copper foil; the substrate to be plated is placed below, and the coating material is bonded to the substrate to be plated.

[0106] Step 4) Scanning and irradiating the fixed substrate to be coated and the coating material by using a laser light source. The diameter of the laser spot is set to 10 microns, and the laser scanning interval is 1 mm. The laser bombards the coating material, and the copper clusters produced by the bombardment sputter the substrate to be plated to form an equidistant c...

Embodiment 3

[0108] Such as Figure 4 As shown, the difference between this embodiment and embodiment 1 is:

[0109] Step 4) Laser direct writing. Set the laser program to triangle, pentagon and English letter "UJN", and write the coating material copper foil directly onto the substrate quartz to be coated, such as Figure 4 SEM patterns of different patterns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com