Meat enzymolysis pet food with antioxidant activity and preparation process of meat enzymolysis pet food

An antioxidant activity and meat enzymatic hydrolysis technology, applied in the field of enzymatic hydrolysis technology, can solve the problems of inability to complete the good cleavage of hydrophobic groups, limited enzyme types, selection, and complicated process stages, so as to improve the rapid development effect, Optimize the effect of anti-infection, aid digestion, and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

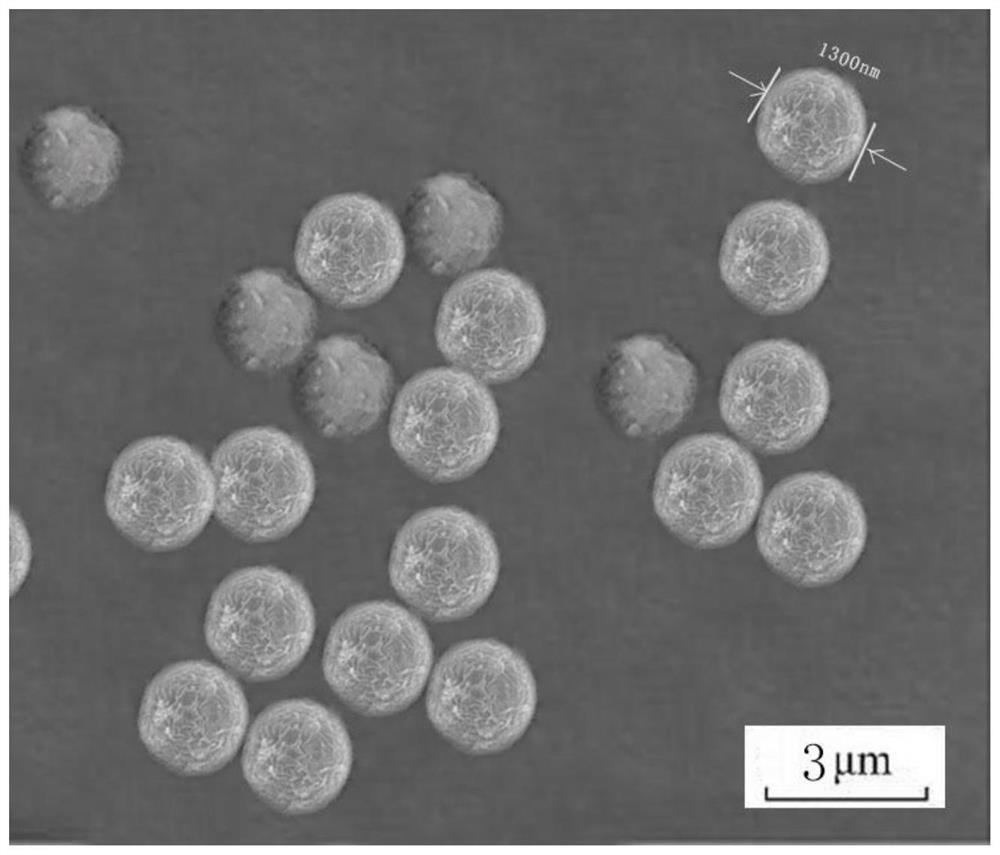

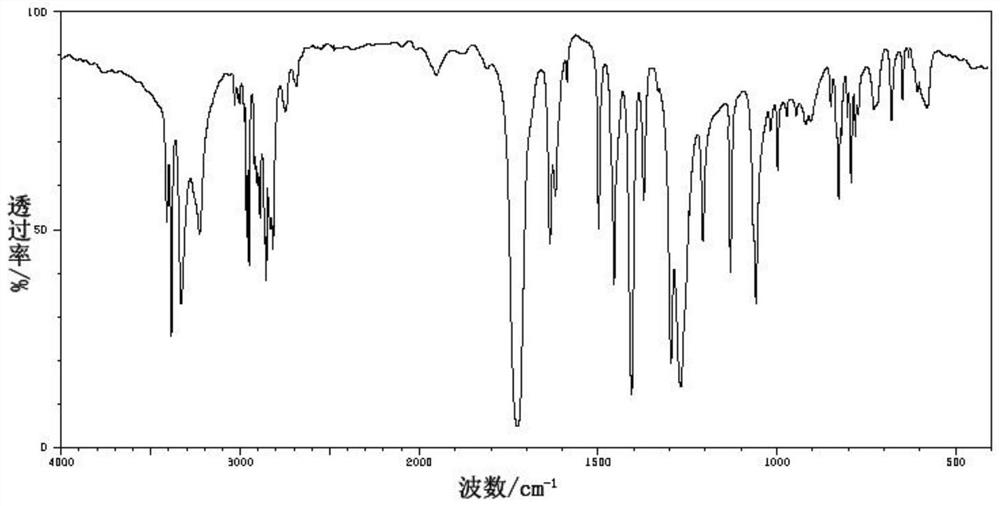

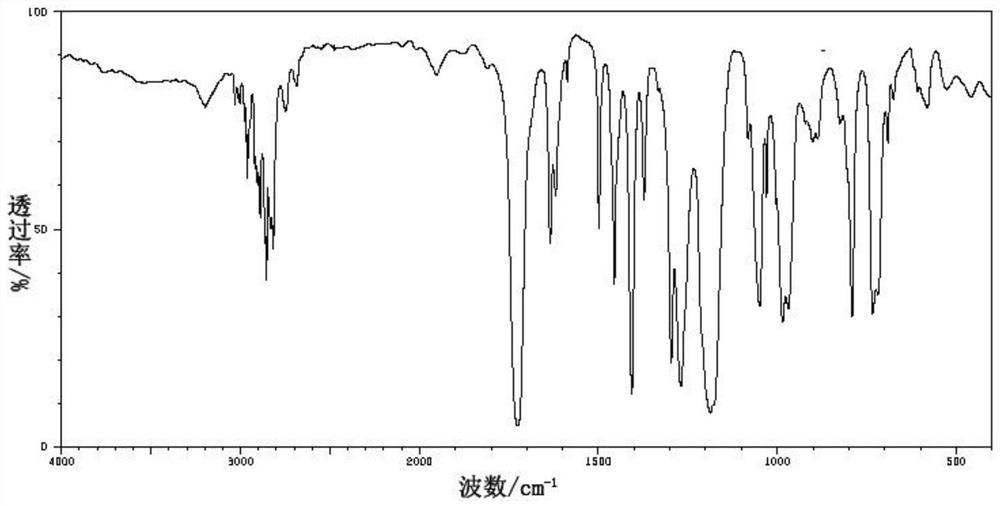

[0026]A preparation process of meat enzymatic hydrolysis pet food with anti-oxidation activity, weighing pre-treated meat, animal offal, meat preferably chicken, chicken offal, adding distilled water or an organic solution containing ethanol at a material ratio of 1:5 , use a high-speed crushing homogenizer to pulverize and homogenize, adjust the pH of the solution to 4-10, control the temperature to 40-70°C, and then form a hydrolyzate by adding 3-5% of the enzyme in the water, and add measurement and control release substances and enzymes again during the hydrolysis process to adjust Hydrolysis conditions continue to hydrolyze to the required supernatant, take the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com