Preparation method of PTFE (Polytetrafluoroethylene) short fiber

A technology of PTFE and short fiber, which is applied in the field of preparation of PTFE fiber, can solve the problem of uneven coating of inorganic metal powder, achieve the effect of increasing the density of the blank, reducing the number of voids, and improving the antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

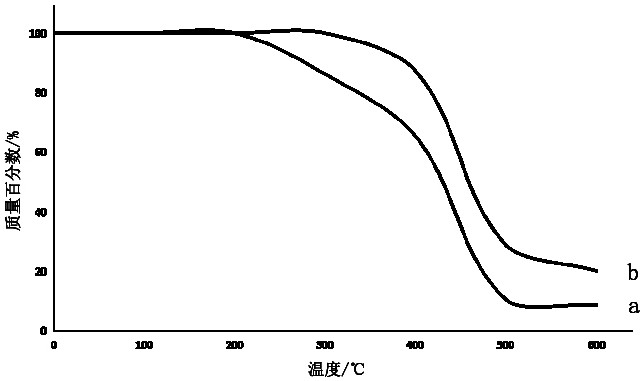

Image

Examples

preparation example Construction

[0023] A kind of preparation method of PTFE short fiber provided by the invention comprises the following steps:

[0024] (1) Pretreatment: Add PTFE particles to the pretreatment agent and mix, wash and dry to obtain composite PTFE powder; wherein, the pretreatment agent includes aniline derivative / polyvinyl alcohol compound;

[0025] (2) Compact: Form a blank from composite PTFE powder at 250~300°C;

[0026] (3) Fabrication of fibers: processing blanks to form fibers by slit film method.

[0027] The above preparation method also includes the following process: after the pretreatment of the PTFE particles, pour them into the mixing tank, add kerosene for mixing, and the ratio of kerosene consumption to the total pellet weight is 40:17~20; after the mixing is completed, put it into a 45°C incubator Insulation and static treatment, the standing time is 12h; after the compact is completed, the billet is water-cooled to cool down; the above-mentioned film cutting method includes...

Embodiment 1

[0029] In this example, the raw materials for the preparation of the aniline derivative / polyvinyl alcohol complex include: N-phenyl-p-phenylenediamine (purity 98%), succinic anhydride (purity 99%), p-chloromethylbenzene Ethylene (purity 99%, containing 100ppm p-tert-butylcatechol stabilizer), tetramethylguanidine (purity 99%), N-n-butylmaleimide (prepared by the reaction of maleic anhydride and n-butylamine , in light yellow oil), azobisisobutyronitrile (purity 98%).

[0030] The preparation method of the preparation of described aniline derivative / polyvinyl alcohol compound is as follows:

[0031] Synthesis of intermediates: Add N-phenyl-p-phenylenediamine (18.42g, 0.1mol) and succinic anhydride (10.0g, 0.1mol) into 600ml of dichloromethane solvent, stir for 12h and filter with suction, collect the gray precipitate and use Wash with ether until the filtrate is colorless, then dry at 40°C to obtain the intermediate;

[0032] Synthesis of monomers: Mix the intermediate (5.68g...

Embodiment 2

[0037] The difference between this example and Example 1 is that the preparation of the aniline derivative / polyvinyl alcohol complex is different, including: pre-preparing polyvinyl alcohol into a polyvinyl alcohol film, and then adding 10 mg to Example 1 to obtain 10 ml Mix and stir in the mixed solution for 6 hours, then take out the polyvinyl alcohol film, wash and dry, and then pulverize to a range of 1-100 μm to obtain a composite.

[0038] In this embodiment, although polyvinyl alcohol has excellent hydrophilicity and dispersibility, the viscosity of polyvinyl alcohol aqueous solution is relatively large, and the styrene monomer containing aniline dimer and N-n-butylmaleimide The degree of freedom is limited in the polyvinyl alcohol solution, which may affect the effect of the polymerization reaction. Therefore, in this embodiment, the polyvinyl alcohol film is used as the matrix to make the styrene monomer containing aniline dimer and N- n-Butylmaleimide is polymerized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com