Carboxyesterase, coding gene, genetically engineered bacterium and application thereof

A technology of genetically engineered bacteria and coding genes, which is applied in the field of carboxylesterase and its coding genes, can solve problems such as environmental pollution, complex chemical processes, and expensive chiral catalysts, and achieve stable effects and high space-time yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

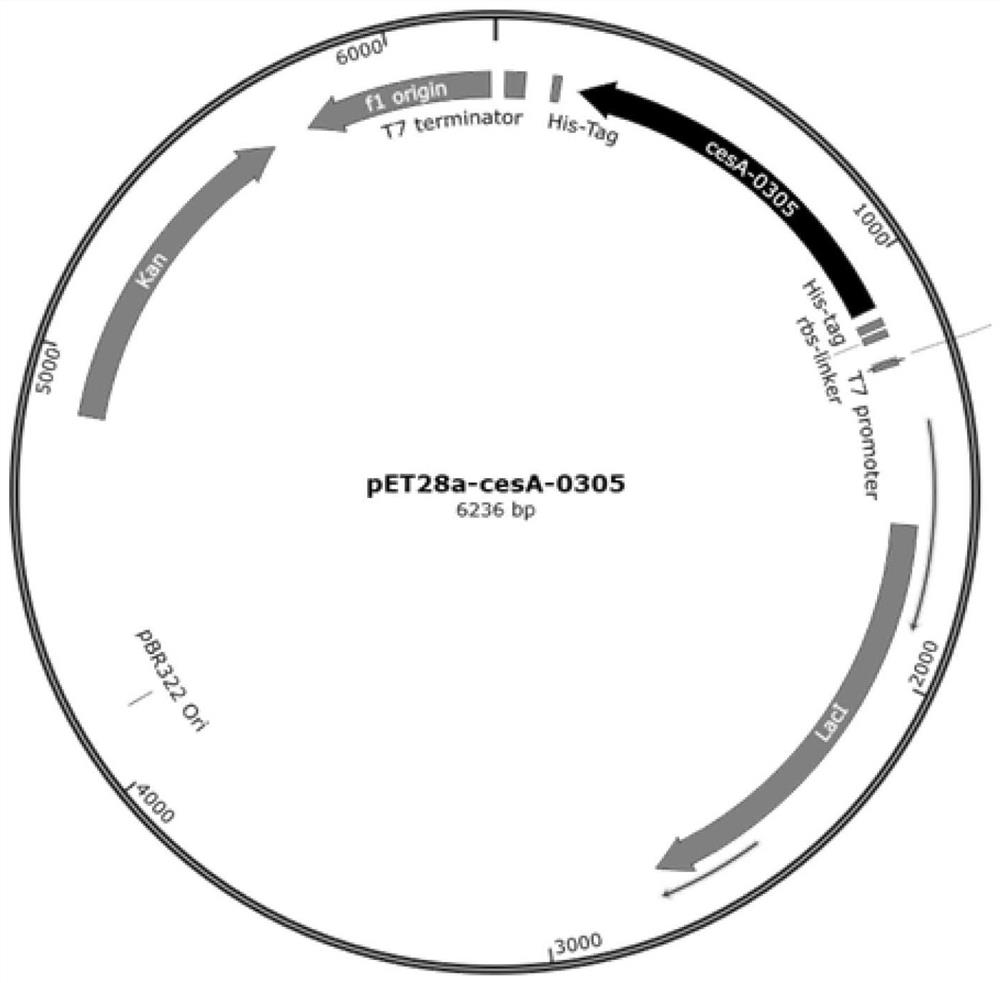

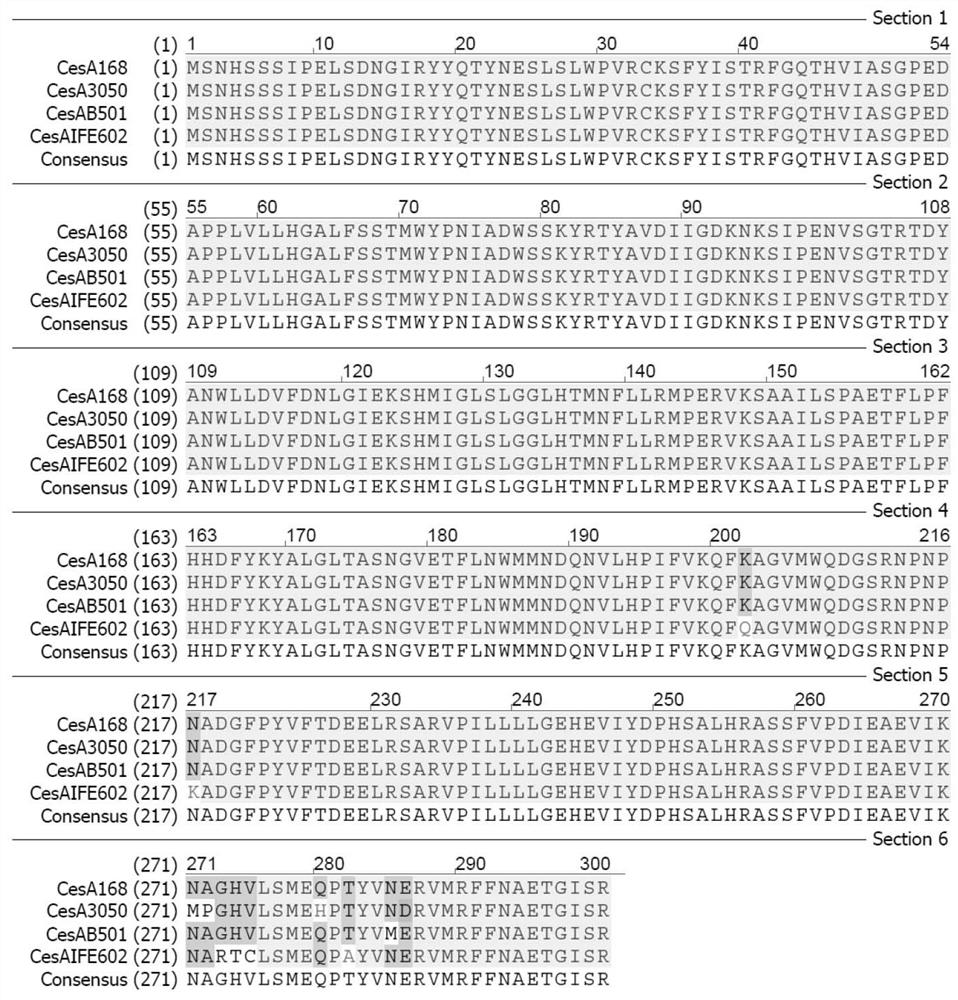

[0025] Embodiment 1: Construction of four kinds of recombinant escherichia coli containing carboxylesterase gene

[0026] (1) Carboxylesterase gene amplification

[0027] Preserved strains isolated from soil samples using the genomic DNA of Bacillus subtilis strain 168 commonly used in the laboratory B. subtilis Genomic DNA of IFE602, metagenomic DNA of sauce koji sample 0305 from a traditional broad bean paste brewing factory in Anhui, metagenomic DNA of a company's biological fertilizer sample B501 were used as DNA templates, and cesA-NdeI-F / cesA-R were used as amplification primers. The high-fidelity enzyme Phanta Max Super-Fidelity DNAPolymerase of Nanjing Nuoweizan Biotechnology Co., Ltd. was amplified by PCR to obtain a series of carboxylesterase genes. The PCR amplification program was: 95 ℃, 3 min; 95 ℃, 15s; 53 ℃, 15 s; 72 °C, 3 min; 30 cycles; 72 °C, 5 min; 4 °C storage. Purification of PCR products was performed using a DNA gel extraction kit.

[0028] cesA-Nde...

Embodiment 2

[0103] Embodiment 2: 2 L fermentation tanks prepare and produce carboxylesterase

[0104] (1) Seed activation

[0105] Four kinds of recombinant Escherichia coli were inoculated into LB medium containing 50 mg / L kanamycin, and cultured at 37 °C and 200 rpm until the mid-logarithmic growth phase to obtain seed liquid.

[0106] (2) The fresh seed solution was inoculated in the fermentation medium containing 0.05% (v / v) defoamer and 50 mg / L kanamycin at an inoculum volume of 5 % by volume. The fermentation temperature was 37 ° C, and the dissolved oxygen DO was controlled. Greater than 20%, use 25% ammonia water to control the pH to be 6.86. Glycerol was fed four hours from the inoculation of the fermenter, 12 h was fed at 30 mL / h / L per hour, lactose was fed for five hours of fermentation, and 10 h was induced at 40 mL / h / L per hour. Feed glycerol composition: 60 g glycerol and 4 g MgSO4 7H2O dissolved in 400 mL deionized water, feed lactose composition: 30 g lactose dissolved i...

Embodiment 3

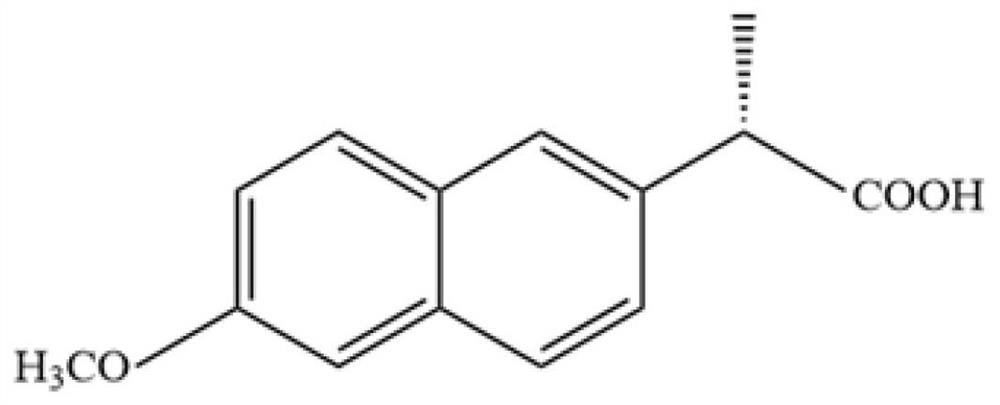

[0108] Embodiment 3: compare the hydrolysis naproxen methyl ester of four different sources of carboxylesterase S - Catalytic activity of naproxen

[0109] Take 1 g of each of the four carboxylesterase-containing wet cells in Example 2, resuspend in 20 mL pH=8 0.2 MNa 2 HPO 4 - Add 10 g / L naproxen methyl ester to the citric acid buffer, stir magnetically in a constant temperature water bath at 40°C, and the reaction solution is used for HPLC analysis. The measured conversion rate and ee p As shown in Table 1. By monitoring the reaction process of the four carboxylesterases at different times, it was found that the conversion efficiency of carboxylesterase 0305 was much higher than that of carboxylesterase B501 and carboxylesterase IFE602, and compared with carboxylesterase 168, carboxylesterase 0305 conversion rate and ee value is better.

[0110]

[0111] (2) HPLC liquid phase detection method: take 100 μL of the reaction solution, add 20 μL of 1mol / L hydrochloric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com