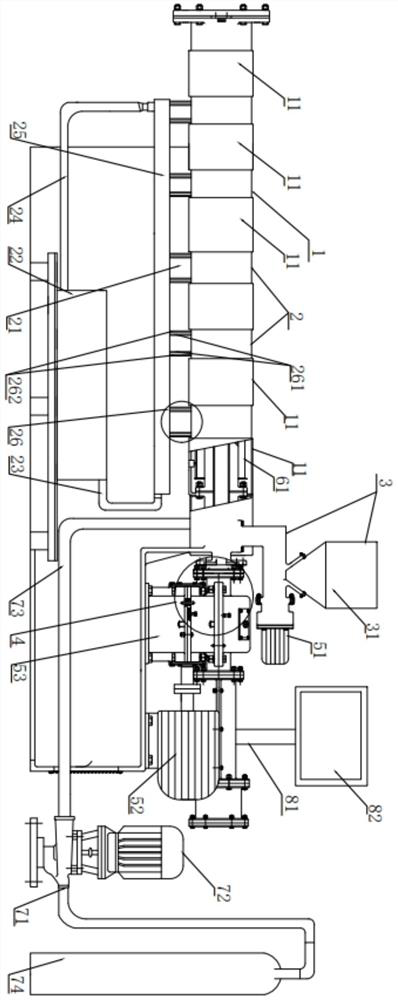

Preparation process of biological ceramic-degradable polymer composite granules

A technology of bioceramics and preparation technology, which is applied in the field of preparation technology of bioceramics-degradable polymer composite granulation, which can solve the problems of poor mechanical strength, not tissue repair and regeneration materials, and high brittleness, so as to improve the mixing uniformity , excellent mechanical properties, full particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

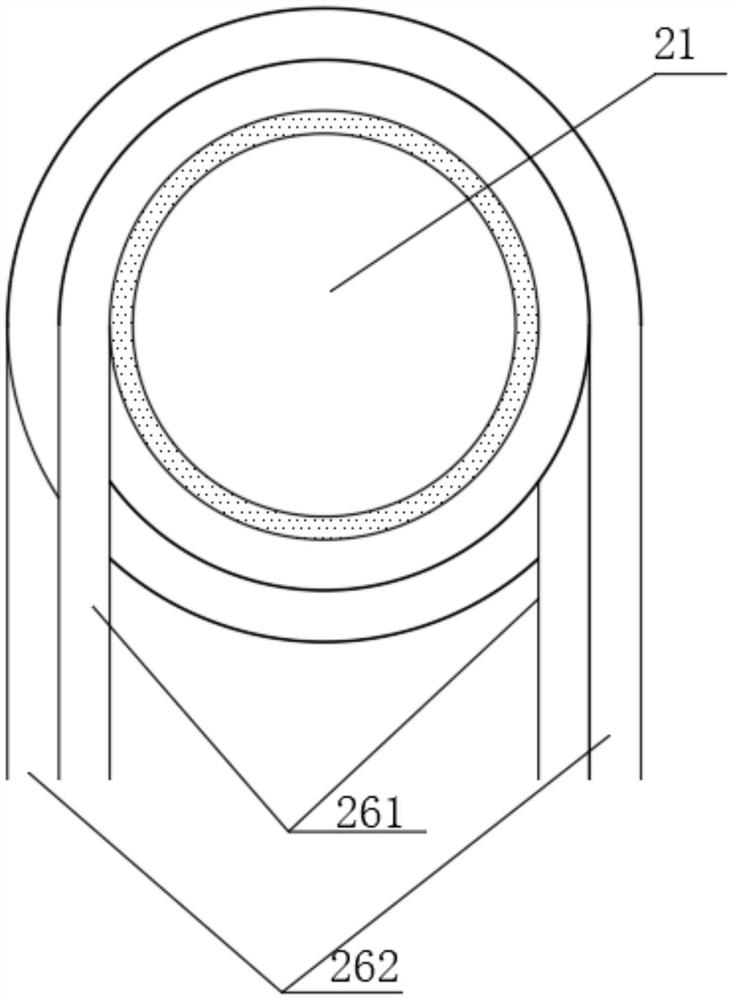

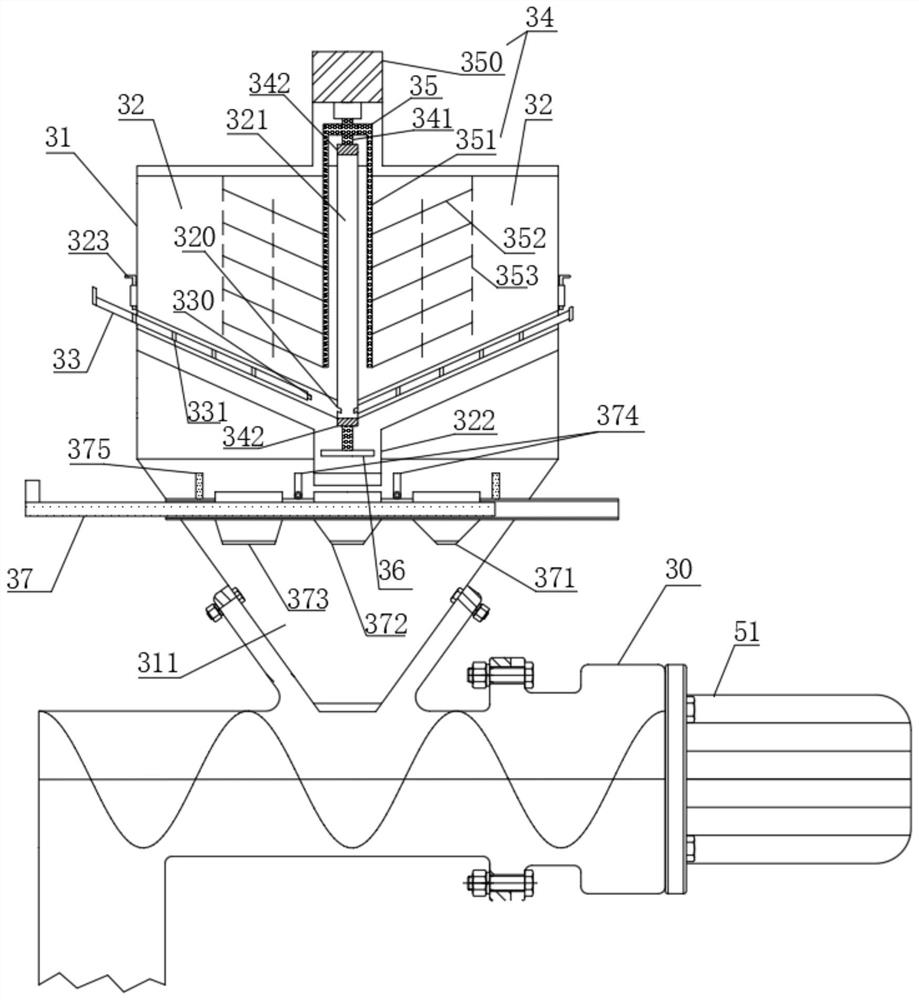

Method used

Image

Examples

Embodiment 1

[0047] Weigh 0.1kg of bioceramic HA powder with a particle size of 10um and 0.9kg of biodegradable polymer material PLA powder with a particle size of 20um according to the mass ratio distribution of 1:9, add the two to the ball mill jar and add large, medium and The mass ratio of small grinding balls is 1:1:1 (the ratio of ball to material is 1:1). First rotate clockwise at 100rad / min, ball milling time is 10min, stop for 1min; then turn counterclockwise, speed is 100rad / min, ball milling time is 10min, stop for 1min; reciprocate; ball milling time is 3h, and bioceramic-can be obtained Degradable polymer mixed powder. Using the above composite powder as raw material, set the temperature of the first to sixth zones of the barrel of the twin-screw extruder, the temperature of the first zone is 170°C, the temperature of the second zone is 175°C, the temperature of the third zone is 170°C, The temperature in the fourth zone is 160°C, the temperature in the fifth zone is 180°C, a...

Embodiment 2

[0053] Weigh 0.2kg of bioceramic HA powder with a particle size of 10um and 0.8kg of biodegradable polymer material PLA powder with a particle size of 20um according to the mass ratio distribution of 1:4, add both to the ball mill jar and add large, medium, and The mass ratio of small grinding balls is 1:3:5 (the ratio of ball to material is 1:1). First rotate clockwise at 100rad / min, ball milling time is 10min, stop for 1min; then turn counterclockwise, speed is 100rad / min, ball milling time is 10min, stop for 1min; reciprocate; ball milling time is 3h, and bioceramic-can be obtained Degradable polymer mixed powder. Using the above composite powder as raw material, set the temperature of the first to sixth zones of the barrel of the twin-screw extruder, the temperature of the first zone is 170°C, the temperature of the second zone is 175°C, the temperature of the third zone is 170°C, The temperature in the fourth zone is 160°C, the temperature in the fifth zone is 180°C, and...

Embodiment 3

[0059] Weigh 0.2kg of bioceramic HA powder with a particle size of 10um and 0.8kg of biodegradable polymer material PLA powder with a particle size of 20um according to the mass ratio distribution of 1:4, add both to the ball mill jar and add large, medium, and The mass ratio of small grinding balls is 1:3:5 (the ratio of ball to material is 1:1). First clockwise rotation speed is 200rad / min, ball milling time is 20min, stop for 2min; then rotate counterclockwise, rotation speed is 200rad / min, ball milling time is 20min, stop for 2min; cycle reciprocating; ball milling time is 4h to obtain bioceramic Degradable polymer mixed powder. Using the above composite powder as raw material, set the temperature of the first to sixth zones of the barrel of the twin-screw extruder, the temperature of the first zone is 170°C, the temperature of the second zone is 175°C, the temperature of the third zone is 170°C, The temperature in the fourth zone is 160°C, the temperature in the fifth zo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com