Preparation method of UV LED photoinitiator

A photoinitiator and solvent technology, applied in the field of UVLED photoinitiator preparation, can solve the problems of unsatisfactory curing effect, large amount of photoinitiator, cost pressure, etc., and achieve high yield, high initiation rate and low mobility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method for UV LED photoinitiator, comprising the following steps:

[0023] (1) Dissolve polyester acrylate (120mmol) in ethanol (2400mmol), add potassium hydroxide (320mmol) and stir for 1h, add isobornyl acrylate (140mmol), after reacting for 13h, add 4-hydroxybenzophenone 5ml quenched the reaction, extracted 3 times with N,N-dimethylformamide, combined the organic phases, washed the organic phase once with saturated brine, dried over anhydrous sodium sulfate, distilled off a large amount of solvent under reduced pressure, and obtained polydimethylformamide Siloxane was used as the mobile phase, and silica gel was used as the stationary phase to perform column chromatography to obtain a white solid with a yield of 98%.

[0024] (2) Dissolve the product from the previous step (50mmol) in chlorobenzene (520mmol), add 2,4,6-trimethylbenzoylphosphonic acid ethyl ester (150mmol), cool to 0°C and add p-cresol dropwise (150 mmol), after the dropwise addition wa...

Embodiment 2

[0028] A preparation method for UV LED photoinitiator, comprising the following steps:

[0029] (1) Dissolve epoxy acrylate (120mmol) in 1,2-dichloromethane (2600mmol), add sodium hydroxide (320mmol) and stir for 3h, add lauric acid acrylate (180mmol), after reacting for 10h, add 4 5ml of -hydroxybenzophenone quenched the reaction, extracted 3 times with N,N-dimethylformamide, combined the organic phases, washed the organic phase with saturated brine once, dried over anhydrous sodium sulfate, and distilled off a large amount of As a solvent, polydimethylsiloxane was used as mobile phase and silica gel was used as stationary phase to perform column chromatography to obtain a white solid with a yield of 96%.

[0030] (2) Dissolve the product from the previous step (50mmol) in 1,2-dichloromethane (550mmol), add 2,4,6-trimethylbenzoylphosphonic acid ethyl ester (180mmol), and cool to 3°C P-cresol (180 mmol) was added dropwise, and after the dropwise addition was completed, stirri...

Embodiment 3

[0034] A preparation method for UV LED photoinitiator, comprising the following steps:

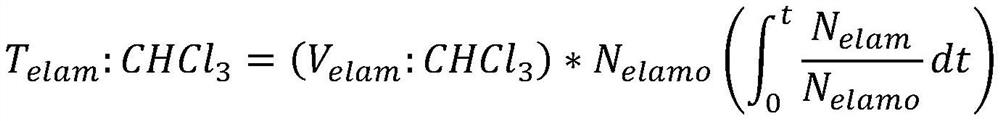

[0035] (1) Dissolve polyether acrylate (120mmol) in chloroform (3600mmol), add sodium hydride (240mmol) and stir for 5h, add 3,3,5-trimethylcyclohexane acrylate (220mmol), react After 15 hours, 5ml of 4-hydroxybenzophenone was added to quench the reaction, extracted three times with N,N-dimethylformamide, the organic phase was combined, washed once with saturated brine, dried over anhydrous sodium sulfate, A large amount of solvent was distilled off under reduced pressure, and column chromatography was performed with polydimethylsiloxane as mobile phase and silica gel as stationary phase to obtain a white solid with a yield of 97%.

[0036] (2) Dissolve the previous step product (50mmol) in chlorobenzene (500mmol) and 1,2-dichloromethane mixed solvent (250mmol), add 2,4,6-trimethylbenzoylphosphonic acid ethyl ester (165mmol ), after cooling to 6°C, p-cresol (165 mmol) was added dropwise, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com