Broad-spectrum durable antibacterial granular urea formaldehyde molding compound

A urea-formaldehyde molding compound and granular technology, applied in the field of granular urea-formaldehyde molding compound, can solve the problems of excessive generation of coarse powder, low drying efficiency, large diameter of clusters, etc., achieve excellent antibacterial effect, increase antistatic, anti-fragmentation Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

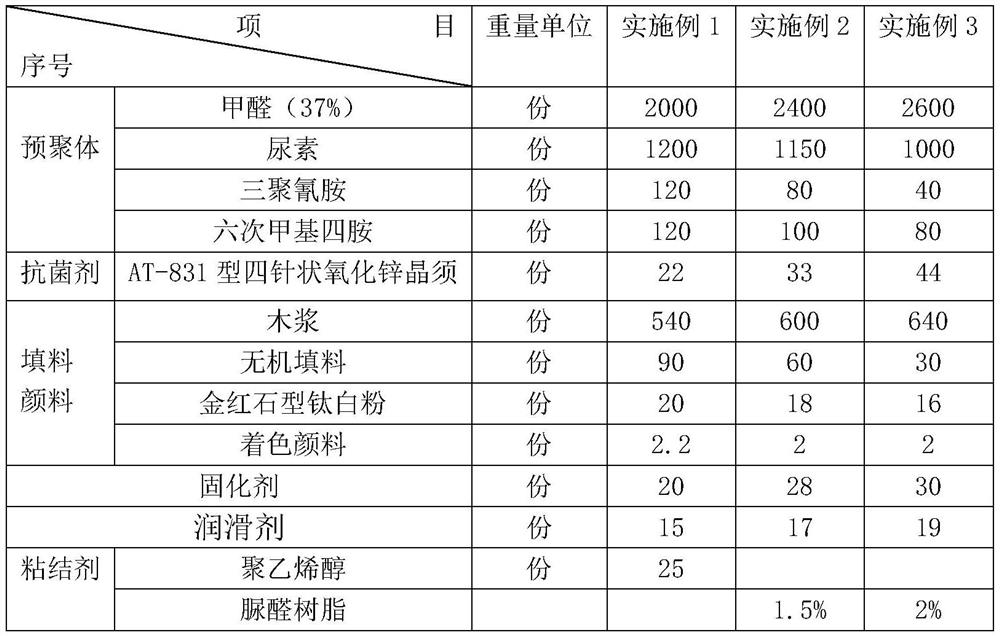

[0066] The broad-spectrum durable antibacterial granular urea-formaldehyde molding compound of the present embodiment includes the components in parts by weight: 1200 parts of urea, 2000 parts of formaldehyde, 120 parts of melamine, 22 parts of four-needle zinc oxide whiskers, and hexamethylene 120 parts of tetraamine, 20 parts of curing agent, 90 parts of talc, 540 parts of coniferous pine pulp, 15 parts of stearic acid, 20 parts of rutile titanium dioxide, and 2.2 parts of organic yellow.

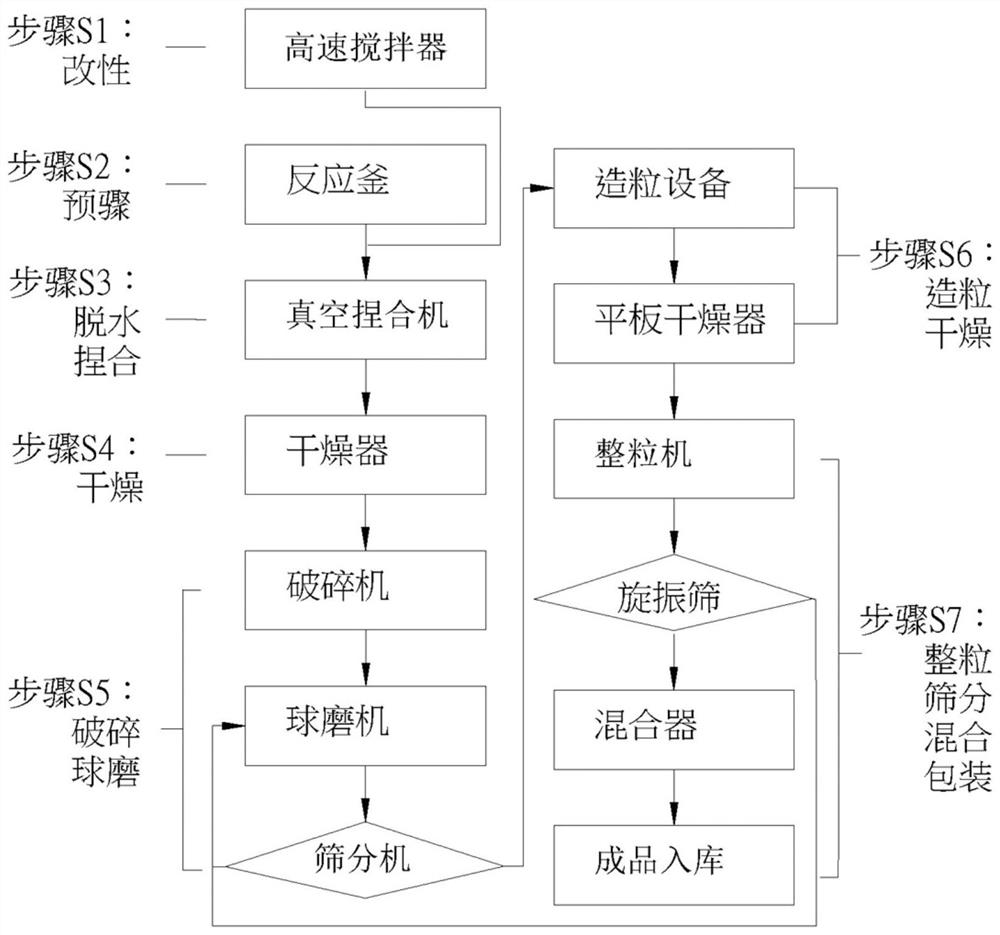

[0067] see figure 1 , the preparation method of the broad-spectrum durable antibacterial granular urea-formaldehyde molding compound of the present embodiment 1, comprising the following steps:

[0068]S1: Surface modification: the four-needle zinc oxide whiskers are subjected to activation treatment surface modification by using a silane coupling agent, and the activation treatment surface modification is carried out in a high-speed stirrer. Add the four-needle zinc oxide whiskers into ...

Embodiment 2

[0079] The broad-spectrum durable antibacterial granular urea-formaldehyde molding compound of the present embodiment includes components in parts by weight: 1150 parts of urea, 2400 parts of formaldehyde, 80 parts of melamine, 33 parts of four-needle zinc oxide whiskers, and hexamethylene 100 parts of tetraamine, 28 parts of curing agent, 60 parts of calcium carbonate, 600 parts of coniferous pine pulp, 15 parts of zinc stearate, 20 parts of rutile titanium dioxide, and 2 parts of high-pigment carbon black.

[0080] The preparation steps of the broad-spectrum durable antibacterial granular urea-formaldehyde molding compound of the present embodiment 2 are:

[0081] S1: Surface modification: the four-needle zinc oxide whiskers are subjected to activation treatment surface modification by using a silane coupling agent, and the activation treatment surface modification is carried out in a high-speed stirrer. Add four-needle zinc oxide whiskers into the device, spray diluted sila...

Embodiment 3

[0092] The broad-spectrum durable antibacterial granular urea-formaldehyde molding compound of the present embodiment includes the components in parts by weight: 1000 parts of urea, 2600 parts of formaldehyde, 40 parts of melamine, 44 parts of four needle-shaped zinc oxide whiskers, and hexamethylene 80 parts of tetramine, 30 parts of curing agent, 30 parts of precipitated barium sulfate, 640 parts of coniferous pine pulp, 19 parts of ethylene stearic acid amide, 16 parts of rutile titanium dioxide, and 2 parts of organic blue.

[0093] The preparation method of the broad-spectrum durable antibacterial granular urea-formaldehyde molding compound in Example 3 is the same as that in Example 2, except that the number of raw materials input is different.

[0094] The raw material formulation components of Examples 1 to 3 of the present invention are shown in Table 1 in parts by weight.

[0095] Table 1 Raw material formula component table

[0096]

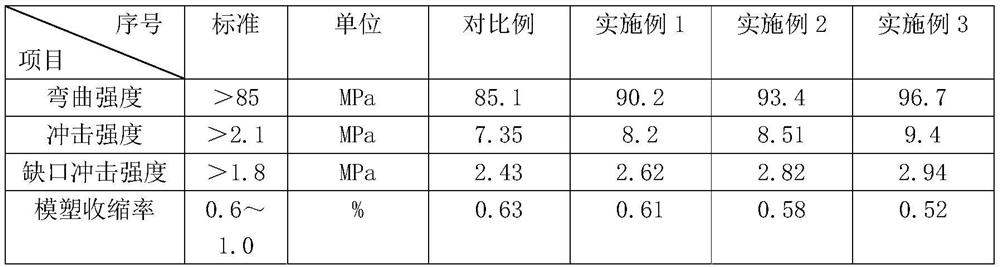

[0097] The invention uses A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com