Infrared ray absorbing coating for automobile glass surface and preparation method of infrared ray absorbing coating

A technology of automotive glass and infrared rays, applied in the direction of radiation-absorbing coatings and coatings, can solve the problems of inability to shield ultraviolet rays, achieve good absorption effect, excellent visible light transmittance, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Components: 25 parts of cesium tungsten bronze nano-dispersion, 7 parts of water-based resin film-forming agent, 1 part of composite coupling agent, 0.5 part of wetting agent, 0.5 part of anti-settling thixotropic agent, 0.2 part of antioxidant, 66.8 parts of water share.

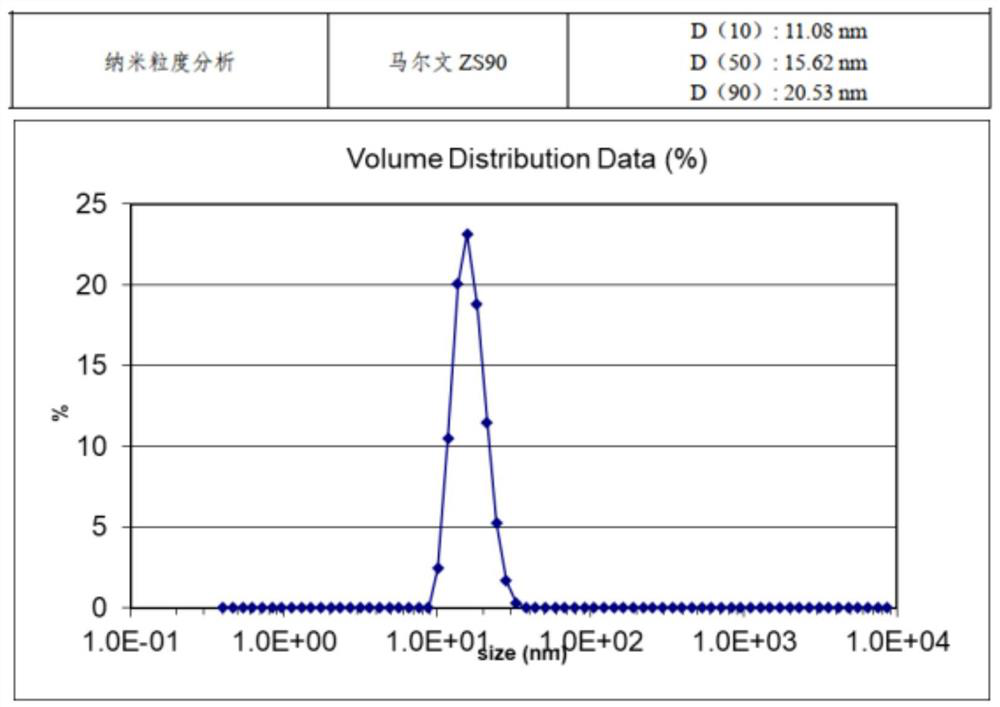

[0044] In this embodiment, the cesium tungsten bronze nano-dispersion is made of 0.2mol / L tungsten hexachloride and 0.07mol / L cesium hydroxide monohydrate as raw materials, citric acid as reducing agent, ethylene glycol: water The volume ratio is 25:75 as a mixed solvent and reacted at 240°C for 24 hours. Wherein, the D50 particle size of this cesium tungsten bronze nano-dispersion is 15.62nm, and the D90 particle size is 20.53nm (its particle size distribution diagram is as attached figure 1 shown).

[0045] In this embodiment, the coupling agent is compounded from 0.2 parts of KH-560, 0.4 parts of KH-792 and 0.4 parts of tetraisopropyl titanate; the water-based resin film-forming agent is water-b...

Embodiment 2

[0047] Components: 20 parts of cesium tungsten bronze nano-dispersion, 5 parts of water-based resin film-forming agent, 3 parts of composite coupling agent, 0.5 part of wetting agent, 0.5 part of anti-sedimentation thixotropic agent, 0.2 part of antioxidant, 70.8 parts of water share.

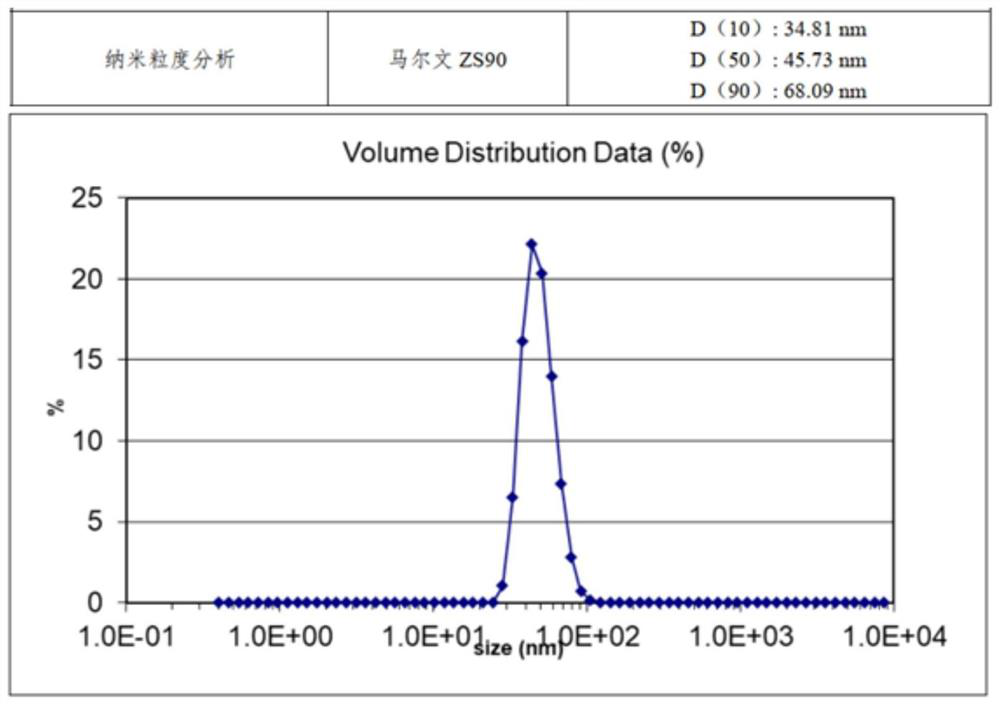

[0048] In this embodiment, the cesium tungsten bronze nano-dispersion is made of 0.2mol / L tungsten hexachloride and 0.07mol / L cesium hydroxide monohydrate as raw materials, acetic acid as a reducing agent, ethanol: water by volume ratio 30:70 as a mixed solvent, reacted at 220 ° C for 22 hours in the system. Wherein, the D50 particle size of this cesium tungsten bronze nano-dispersion is 15.62nm, and the D90 particle size is 20.53nm (its particle size distribution diagram is as attached figure 2 shown).

[0049] In this embodiment, the coupling agent is compounded from 1 part of KH-560, 1 part of KH-6021 and 1 part of tetraisopropyl titanate; the water-based resin film-forming agent is polyv...

Embodiment 3

[0051] Components: 22 parts of cesium tungsten bronze nano-dispersion, 5 parts of water-based resin film-forming agent, 1 part of composite coupling agent, 0.5 part of wetting agent, 0.3 part of anti-sedimentation thixotropic agent, 0.1 part of antioxidant, 71.1 parts of water .

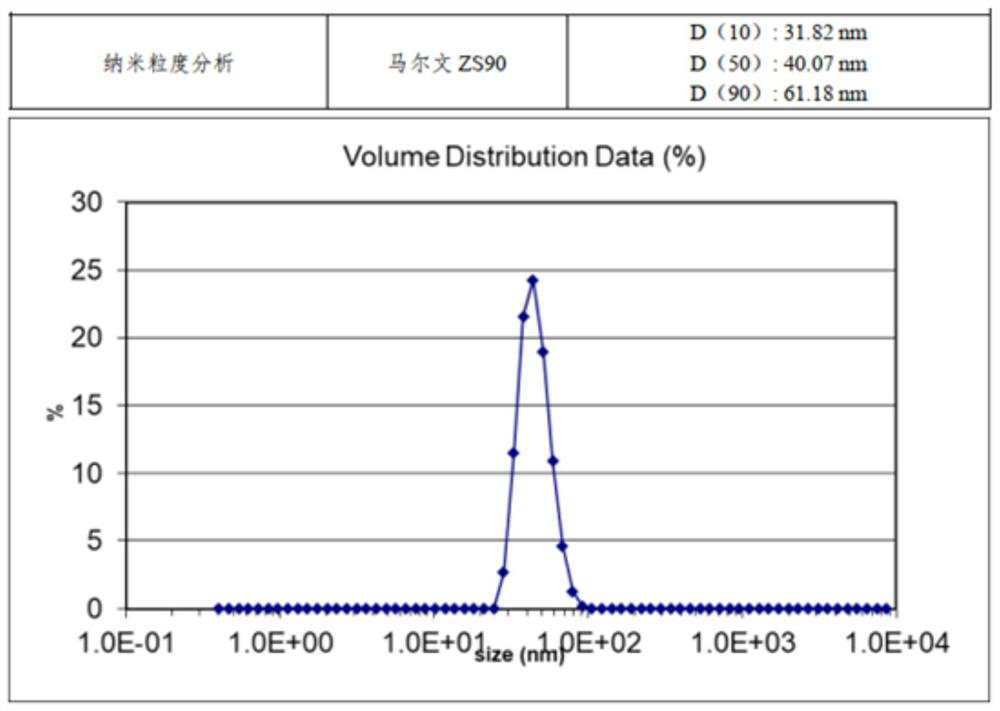

[0052] In the present embodiment, the cesium tungsten bronze nano-dispersion is made of 0.3mol / L sodium tungstate and 0.1mol / L cesium carbonate as raw materials, citric acid as reducing agent, ethanol: water with a volume ratio of 30: 70 was used as a mixed solvent and prepared by reacting at 220°C for 22 hours. Wherein, the D50 particle size of this cesium tungsten bronze nano-dispersion is 40.07nm, and the D90 particle size is 61.18nm (its particle size distribution diagram is as attached image 3 shown).

[0053] In the present embodiment, the coupling agent is compounded from 0.3 parts of KH-560, 0.35 parts of KH-550 and 0.35 parts of bis(dioctyloxypyrophosphate) ethylene titanate; the The wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com