Gallium nitride nano superstructure, preparation method thereof and gallium nitride-based laser

A gallium nitride nano- and gallium nitride-based technology, which is applied in the field of gallium nitride-based lasers, gallium nitride nano-superstructure and its preparation, can solve the unfavorable development of high integration and miniaturization, and the low utilization rate of outgoing light energy , large metal absorption loss and other problems, to achieve the effect of high integration, high hardness, and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

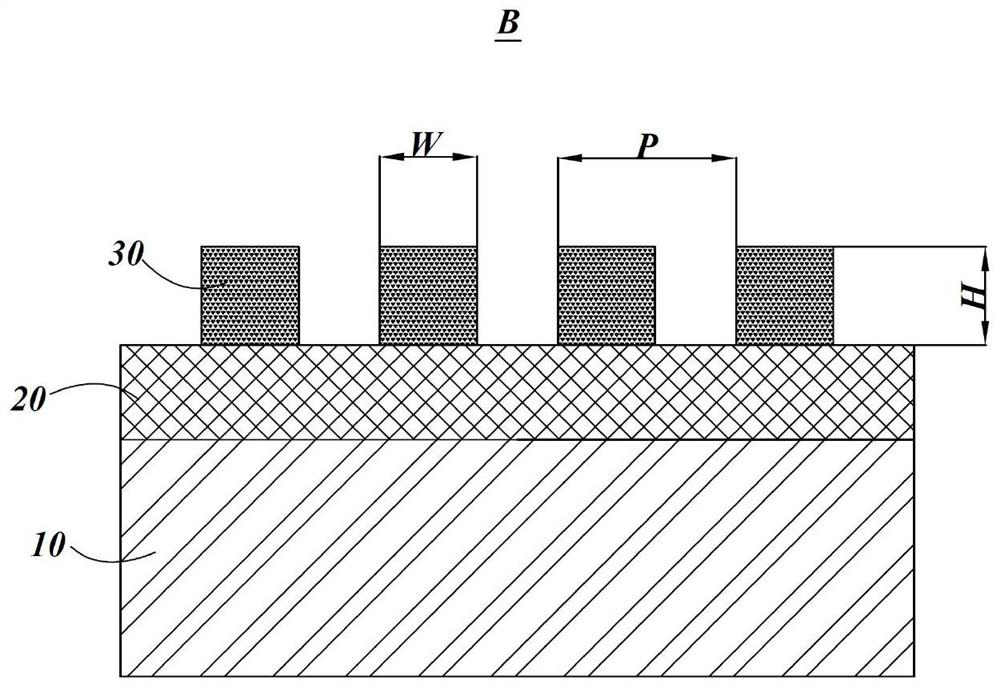

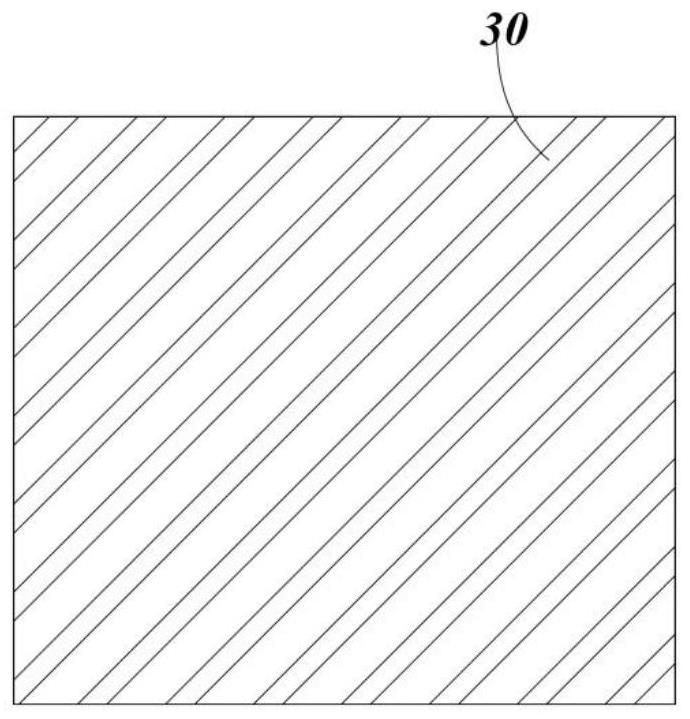

[0030] Such as figure 1 and figure 2 As shown, one embodiment of the present invention provides a gallium nitride nanosuperstructure B for integrating on a gallium nitride-based laser chip to realize circularly polarized light output from a gallium nitride-based laser. The gallium nitride nanosuperstructure is from bottom to top It includes a substrate 10 , a dielectric film layer 20 and a nano grating structure layer 30 in sequence. The size of the gallium nitride nano superstructure is 10-1000um, and the contour shape can be circular or square. The substrate 10 of the gallium nitride nano-superstructure is one of gallium nitride or sapphire. The material of the dielectric film layer 20 is one of gallium nitride, n-type gallium nitride or p-type gallium nitride, and the thickness range is 0.1um-100um. The nano-grating structure layer 30 of the gallium nitride nano-superstructure, the grating material is one of gallium nitride or n-type gallium nitride or p-type gallium ni...

Embodiment 2

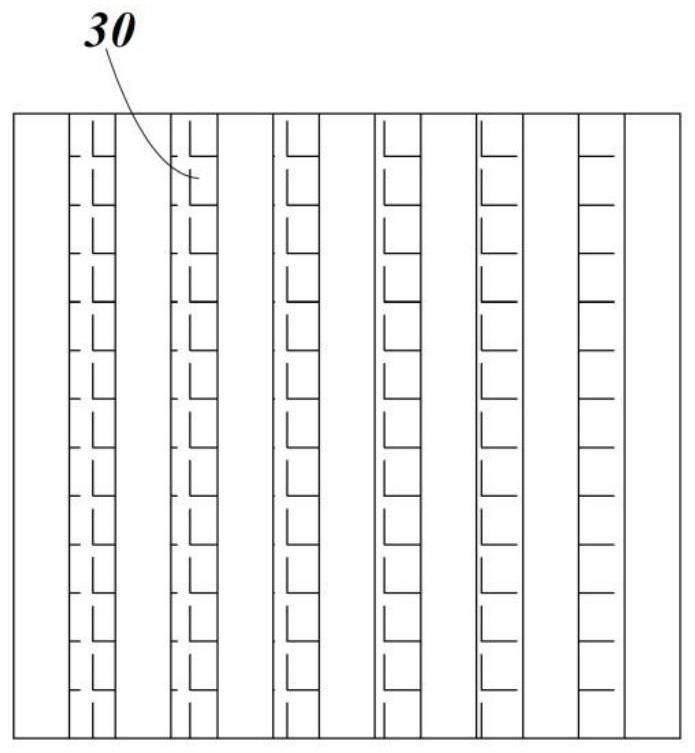

[0032] Since the above-mentioned gallium nitride nano-superstructure is used in an integrated gallium nitride-based laser, the wire grid direction of the prepared nano-grating structure layer 30 should maintain an angle of 45° with the laser chip radiation polarization direction. In order to simplify the gallium nitride The step of integrating the nano-superstructure into the gallium nitride-based laser, when the profile of the prepared gallium nitride nano-superstructure is square, a nano-grating structure with an orientation of 45° to the straight side of the substrate can be directly prepared on the dielectric film layer 20 Layer 30, Ref. image 3 shown.

[0033] refer to Figure 4As shown, the present invention also provides a method for preparing a gallium nitride nano-superstructure for realizing circularly polarized output of gallium nitride-based lasers, comprising, selecting a sapphire substrate, growing gallium nitride or n-type gallium nitride or p-type gallium ni...

Embodiment 3

[0036] Firstly, the GaN thin film grown on the sapphire substrate 10 or the GaN single crystal substrate is directly spin-coated with 200 nm of photoresist. A grating pattern with a period of 220nm and a width of 140nm is exposed by electron beam lithography or double-beam ultraviolet exposure, and developed. Electron beam evaporation or magnetron sputtering is used to vapor-deposit metal chromium with a thickness of 50 nm on the above-mentioned structure, and the photoresist structure is removed by ultrasonic soaking in acetone. At this time, the width of the metal chromium grating is 80 nm. The gallium nitride is etched by dry etching (ICP) to a depth of 225nm and a width of 80nm, and residual chromium is washed away using a chromium etching solution. The transmittance lines and the phase difference and amplitude of the prepared gallium nitride supernanostructures in the blue light broad spectrum band, such as Figure 5a and Figure 5b shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com