Molybdenum diselenide modified nitrogen-doped graphene composite material and preparation method thereof, and nitrogen-doped graphene-based lithium-sulfur battery positive electrode material

A technology of nitrogen-doped graphene and molybdenum diselenide is applied in the field of molybdenum diselenide modified nitrogen-doped graphene composite material and its preparation, and the cathode material of nitrogen-doped graphene-based lithium-sulfur battery can solve the problem of reducing coulombs. Efficiency, low conductivity, inability to meet requirements and other problems, to achieve the effect of improving cycle performance, simple preparation method and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

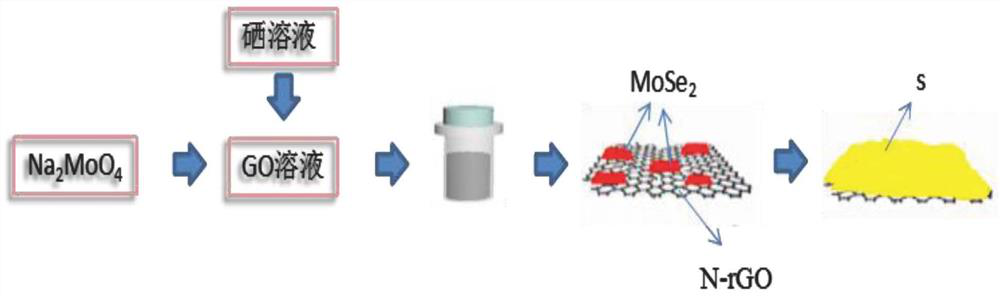

[0075] The present invention also provides a preparation method of molybdenum diselenide / nitrogen-doped graphene composite material, comprising the following steps:

[0076] 1) After the graphene dispersion and the molybdenum source are dispersed, the dispersion is obtained;

[0077] After mixing the selenium source and the liquid nitrogen source, a mixed solution is obtained;

[0078] 2) Mix the dispersion liquid and the mixed liquid obtained in the above steps again, carry out hydrothermal reaction and calcination, and obtain the molybdenum diselenide / nitrogen-doped graphene composite material.

[0079] The present invention firstly disperses the graphene dispersion liquid and the molybdenum source to obtain the dispersion liquid;

[0080] After mixing the selenium source and the liquid nitrogen source, a mixed solution is obtained.

[0081] In principle, the present invention has no special restrictions on the mass concentration of the graphene dispersion, and those skilled...

Embodiment 1

[0121] Preparation of S / MoSe 2 @N-rGO Composite:

[0122] 1] 50mg rGO was dispersed in 50mL mixed solution (H 2 O:DMF=2:3). Add 0.1mmol Na 2 MoO 4 2H 2 O, ultrasonic dispersion is uniform, and solution A is prepared;

[0123] 2] Dissolve a certain amount of selenium powder in 10mL of 80% N 2 h 4 ·H 2 O, stirred at room temperature for 1h. Configuration selenium solution.

[0124] 3] Add the selenium solution obtained in step 2] to the solution in step 1], stir evenly, then transfer to a hydrothermal kettle and heat at 200°C for 12 hours. Freeze-dried after washing, and treated at 800°C for 2h to obtain MoSe 2 Composites for @N-rGO.

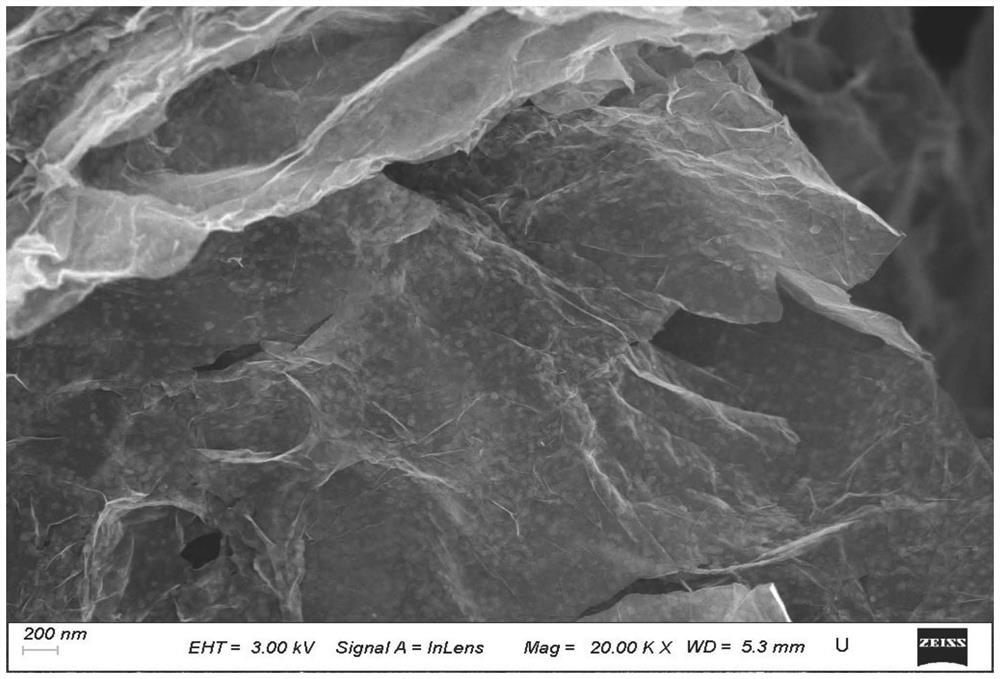

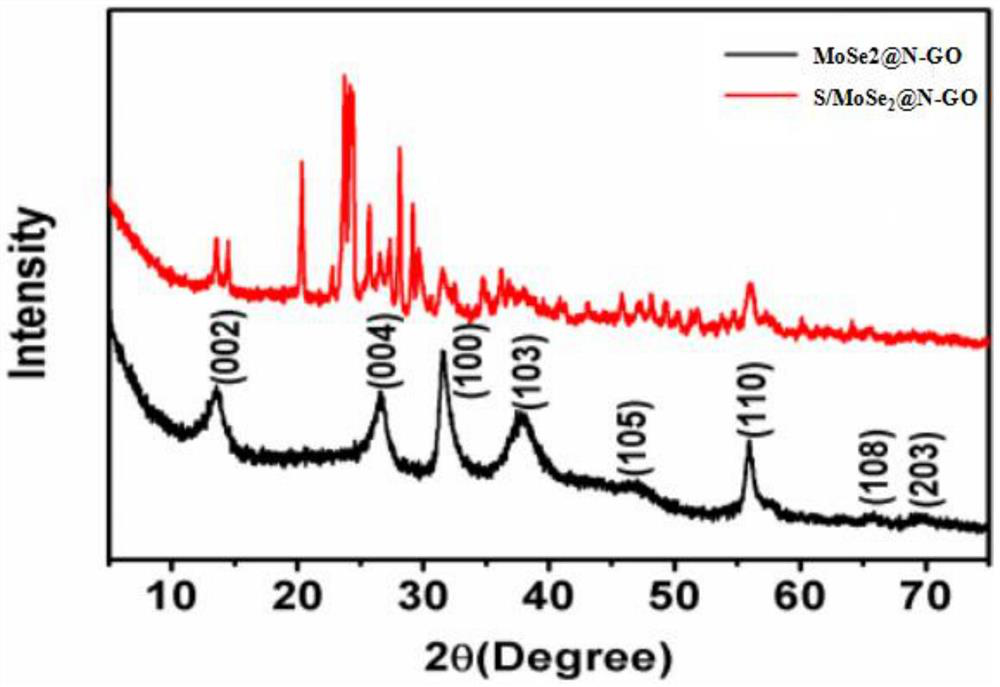

[0125] The molybdenum diselenide / nitrogen-doped graphene composite material prepared in Example 1 of the present invention was characterized.

[0126] see figure 2 , figure 2 MoSe prepared for Example 1 of the present invention 2 SEM scanning electron microscope image of @N-rGO.

[0127] Depend on figure 2 It can be seen that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com