Powdery lead-free preserved egg stabilizer and preparation process thereof

A lead-free preserved egg and preparation process technology, applied in the field of food processing, can solve the problems of excessive copper ion infiltration rate, poor thermal stability of copper hydroxide, black spots on the eggshell of preserved eggs, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In a preferred embodiment, the powdered lead-free preserved egg stabilizer of the present invention is prepared from the following raw materials (by weight):

[0036] 30kg of copper sulfate pentahydrate; 15kg of sodium bicarbonate; 3.5kg of sodium hydroxide; 4kg of 2000-mesh ordinary graphite powder, 4kg of 500-mesh macroporous activated carbon powder; and an appropriate amount of water.

[0037] The preparation technology of the powdery lead-free preserved egg stabilizer of the present embodiment comprises the following steps:

[0038] S1: mix 30kg of copper sulfate pentahydrate, 4kg of activated carbon powder and 160kg of water, and stir to obtain the first suspension;

[0039] S2: mix 15kg sodium bicarbonate, 4kg graphite powder and 160kg water, stir to obtain the second suspension;

[0040] S3: dropping the second suspension into the first suspension at a speed of 0.5L / min continuously and at a roughly uniform speed, stirring while adding, and stirring uniformly to...

Embodiment 2

[0046] The preparation raw materials and preparation process of the powdered lead-free preserved egg stabilizer of Example 2 are the same as those of Example 1, except that the following two points are slightly different.

[0047] The difference between the preparation raw materials of Example 2 and Example 1 is that it is not ordinary graphite powder, but 400g of 2000-mesh graphite oxide powder, which is obtained by the inventor using 2000-mesh ordinary graphite powder by Hummer method. There are methods commonly used in the art for preparing graphite oxide (GO). It should be noted that the particle size of graphite oxide powder may not be maintained at 2000 mesh after being made, but the present invention still denotes it as "2000 mesh graphite oxide powder", which only means that its raw material is 2000 mesh ordinary graphite powder.

[0048] The preparation process of Example 2 is different from that of Example 1 in that S2: mix 15kg of sodium bicarbonate, 4kg of graphite...

Embodiment 3-6

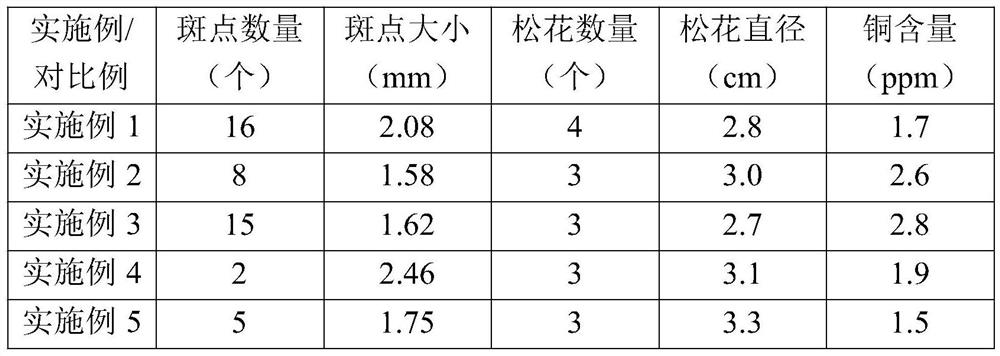

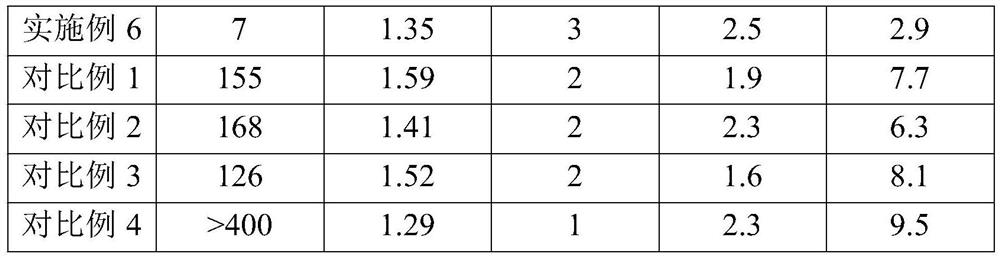

[0050] The preparation raw materials and preparation process of the powdered lead-free preserved egg stabilizer of embodiment 3-6 are basically the same as those of embodiment 1-2, and the difference is only in the type and mesh number of graphite powder and the mesh number of activated carbon powder, as shown in the following table :

[0051] Example Types of graphite powder Graphite powder mesh Activated carbon powder mesh Example 1 Ordinary graphite 2000 500 Example 2 oxidised graphite 2000 500 Example 3 Ordinary graphite 1000 200 Example 4 oxidised graphite 1000 200 Example 5 Ordinary graphite 800 100 Example 6 oxidised graphite 800 100

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com