Alkali cobalt carbonate nanometer material for electrochemical sensor and preparation method and application of basic cobalt carbonate nanometer material

A cobalt carbonate nanometer and sensor technology, applied in cobalt carbonate, material electrochemical variables, material analysis by electromagnetic means, etc., can solve the problem of poor detection reproducibility and stability, easy to be interfered by other substances, low sensitivity of cadmium ions, etc. problems, to achieve the effects of easy analysis, improved electrochemical response, and strong anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

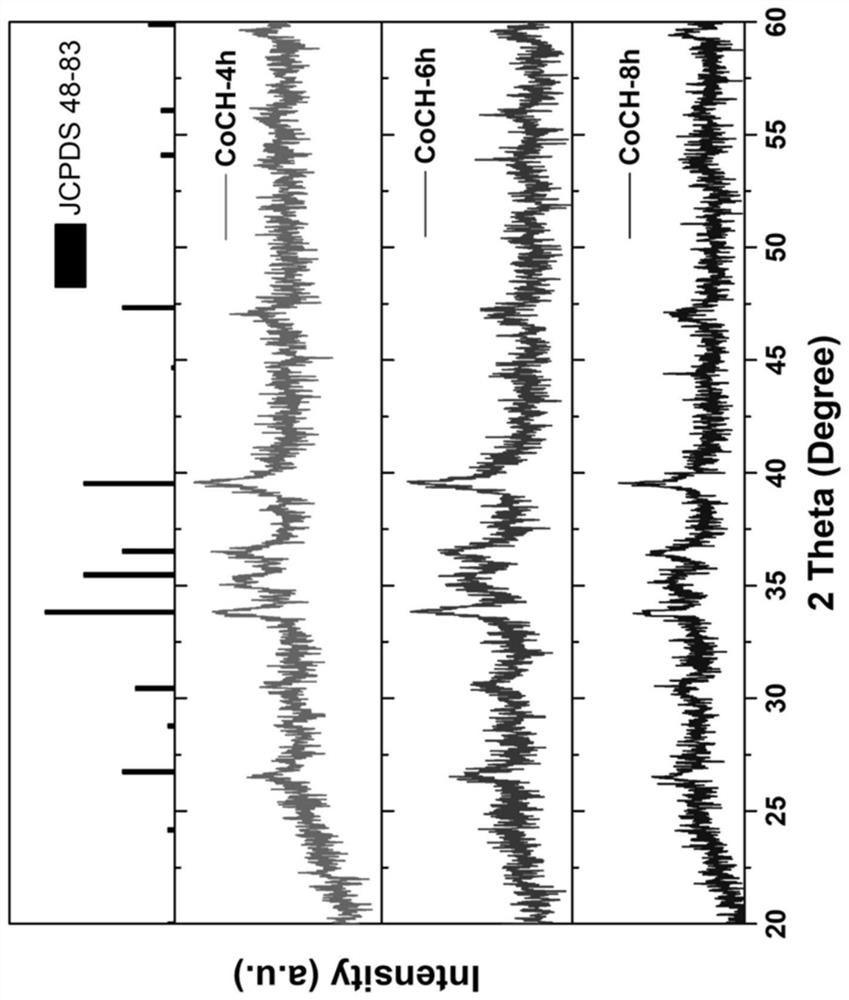

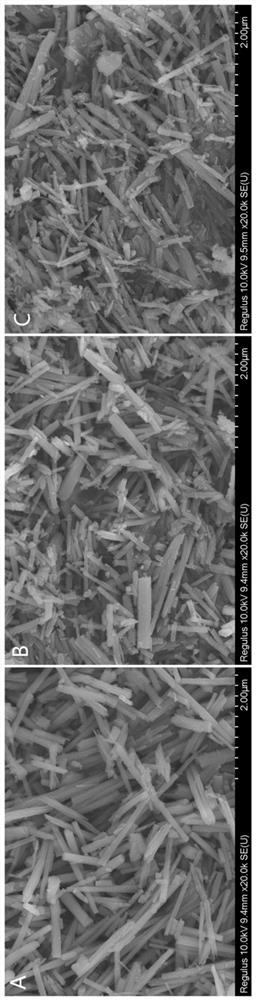

[0051] Synthesis and characterization of basic cobalt carbonate nanomaterials:

[0052] Dissolve 0.87g of cobalt nitrate hexahydrate, 0.9g of urea and 0.22g of ammonium fluoride in 80mL of deionized water, transfer the well-stirred solution to the reaction kettle, and place it in a 120°C atmospheric oven to react for 4 hours and 6 hours, respectively. and 8 hours, cooled to room temperature, taken out, centrifuged the sample (8000r / min) for 10 minutes, washed three times with deionized water and ethanol, and dried at 80 °C for 4 hours under normal pressure to obtain a purple-red powder, that is, prepared Three basic cobalt carbonate nanomaterials with different particle sizes (CoCH-4h, CoCH-6h, CoCH-8h).

[0053] The morphology, lattice structure and chemical composition of CoCH materials synthesized at different preparation times were characterized by scanning electron microscope-X-ray energy dispersive spectrometer (SEM-EDS) and X-ray diffraction (XRD).

[0054] In order to...

Embodiment 2

[0060] Preparation of basic cobalt carbonate modified electrode:

[0061] Take a little alumina powder (0.3μm and 0.05μm) on the chamois, add double distilled water to make it into a suspension, grind and polish the glassy carbon electrode (GCE) until the mirror surface is smooth, and then rinse the glassy carbon electrode with double distilled water The surface was cleaned until clean, followed by ultrasonic cleaning with acetone, nitric acid (1:1, v / v), NaOH aqueous solution (50%, w / w), double distilled water and ethanol, and then dried under infrared light for use. Take 1 mg of each of the three basic cobalt carbonate nanomaterials prepared in Example 1, then add 200 μL of ethanol respectively, and ultrasonically mix them evenly to obtain CoCH-4h solution, CoCH-6h solution, and CoCH-4h solution with a concentration of 5 μg / μl. 8h solution, respectively take 3 μL of the obtained solution and drop it on the glassy carbon electrode (diameter 3mm) treated above (the drop coatin...

Embodiment 3

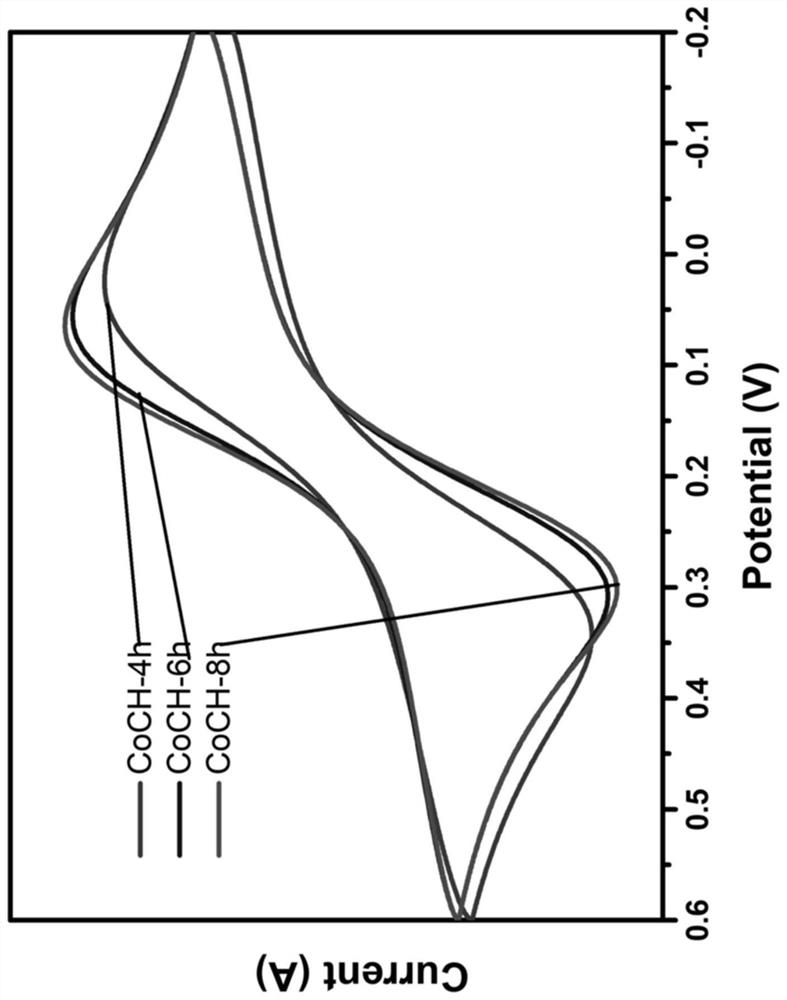

[0063] The electrochemical behavior of the basic cobalt carbonate modified electrode prepared in Example 2 was evaluated:

[0064] image 3 For CoCH-4h / GCE, CoCH-6h / GCE, CoCH-8h / GCE at 5 mmol·L -1 K 3 [Fe(CN) 6 ] / K 4 [Fe(CN) 6 ] 0.1mol·L -1 The CV scanning diagram in the KCl solution of the modified electrode can determine the electrochemical performance of the modified electrode by studying the difference in the magnitude of the redox peak current and the peak potential presented by different electrodes. like image 3 As shown, with the increase of synthesis time, Fe 2+ / Fe 3+ The redox peak current of the electrode pair on CoCH gradually increases, and the redox peak potential difference (ΔEp) also gradually decreases, indicating that the CoCH-8h modified electrode has the strongest catalytic effect on the redox reaction, and the redox reaction on the surface of the electrode has the strongest effect. Reversibility is the best. Combining the characterization result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com