Manganese tailing slag-based baking-free brick as well as preparation method and application thereof

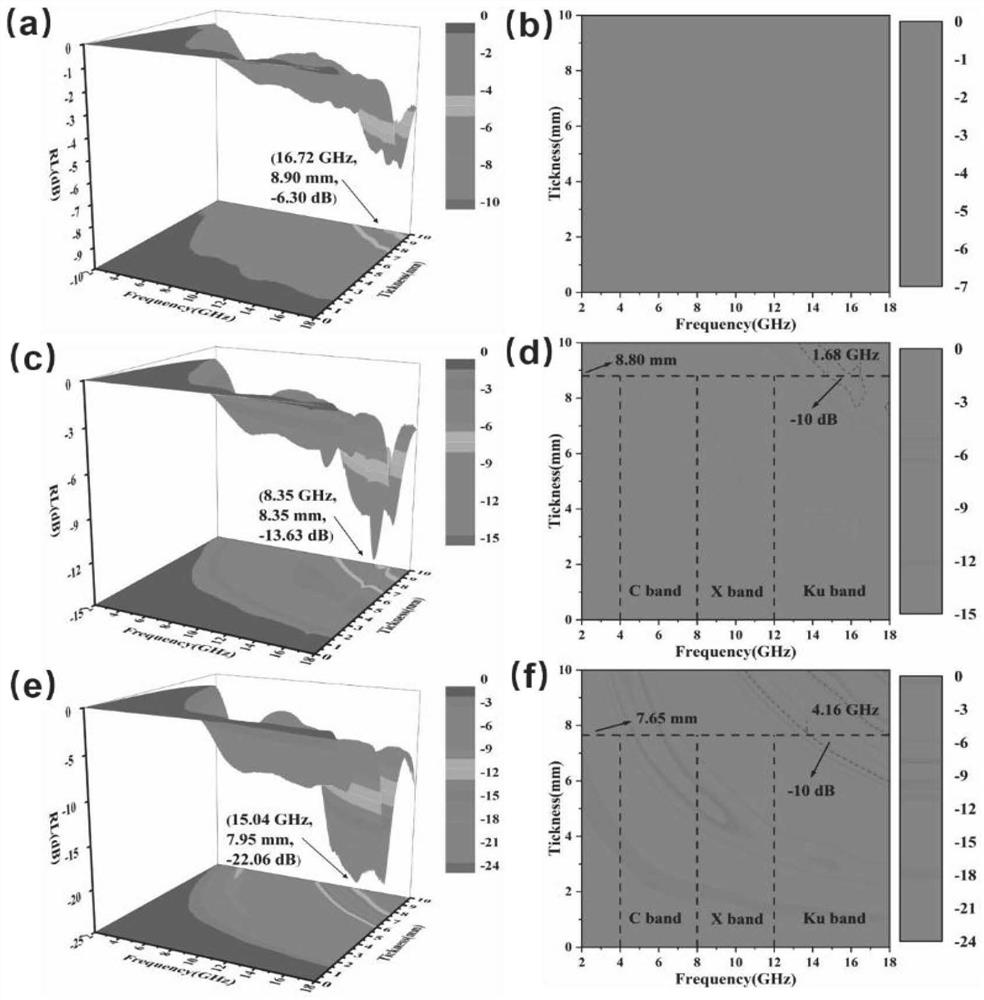

A technology of avoiding burning bricks and tailings slag, which is applied in the field of wave-absorbing materials, can solve problems such as difficulty in meeting requirements, large differences in slag composition, and poor electromagnetic wave-absorbing effect, and achieve industrial production, low raw material costs, and increased additional value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of a low-grade manganese tailings slag-based unburned brick with electromagnetic wave absorption function, the preparation method comprises the following steps:

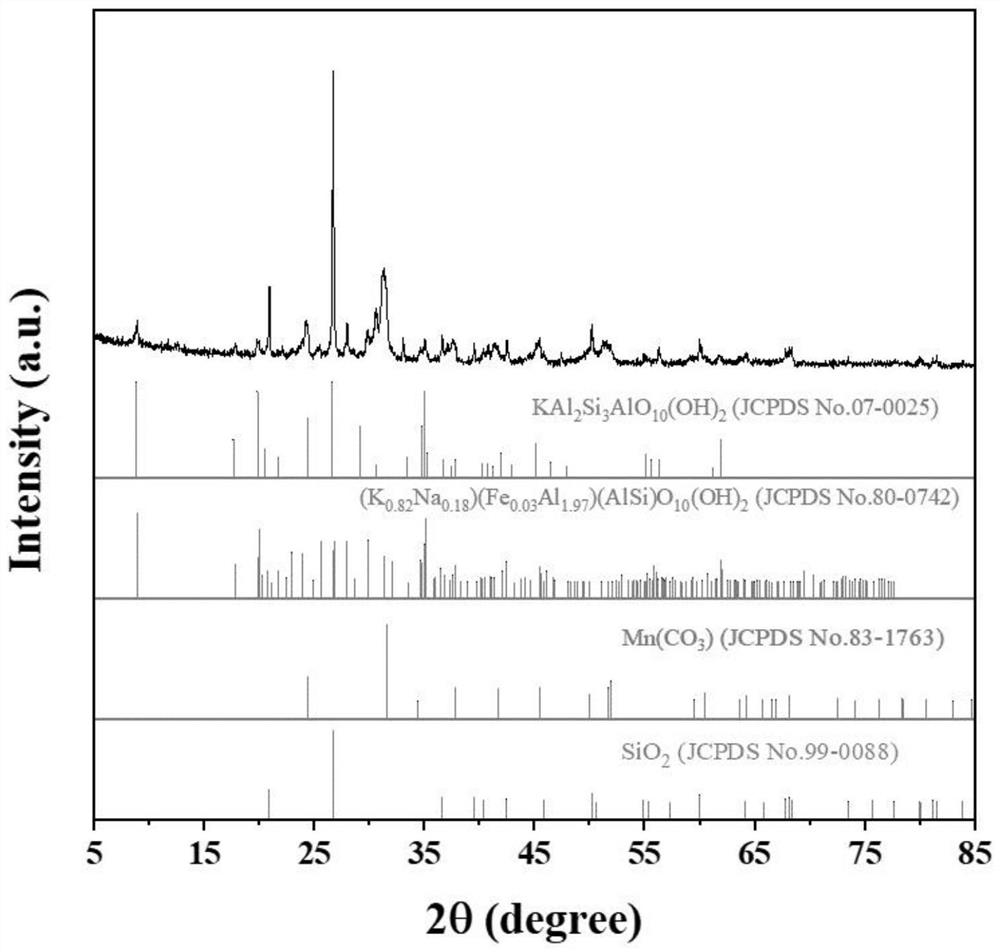

[0053] 1. After grinding and mixing low-grade manganese slag and calcareous material, preheat at 700°C and roast at 1100°C in turn, and use calcareous material to remove Mn in low-grade manganese slag. 2+ and NH + 4 -N and other pollutants, the roasted material is cooled and finely ground through the tube to obtain harmless granulated blast furnace manganese slag. At the same time, the mixed calcination of low-grade manganese slag and calcareous materials will produce FeSiAl alloy powder, magnesium manganese ferrite, etc.

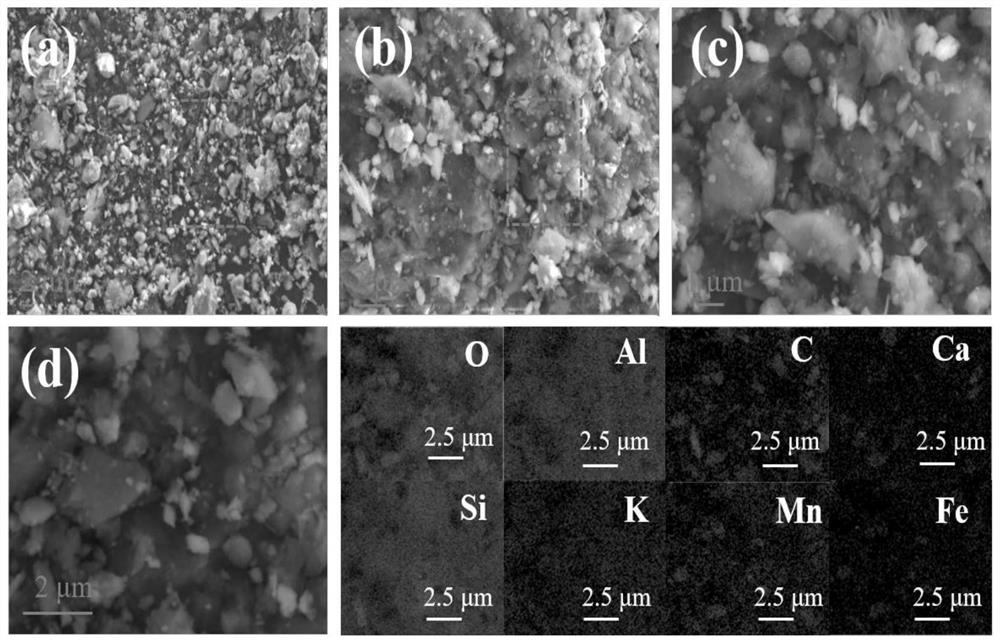

[0054] Among them, the main components and mass ratio of low-grade manganese slag are: silicon dioxide (SiO 2 ) 31.38%; ferric oxide (Fe 2 O 3) 10.71%; calcium oxide (CaO) 9.45%; magnesium oxide (MgO) 7.53%; aluminum oxide (Al 2 O 3 ) 4.82%; manganese oxide (MnO)...

Embodiment 2

[0063] A preparation method of a low-grade manganese tailings slag-based unburned brick with electromagnetic wave absorption function, the preparation method comprises the following steps:

[0064] 1. After grinding and mixing low-grade manganese slag and calcareous material, preheating at 800°C and roasting at 1000°C in turn, the roasted material is cooled and finely ground through a tube to obtain harmless granulated blast furnace manganese slag.

[0065] Among them, the main components and mass ratio of low-grade manganese slag are: silicon dioxide (SiO 2 ) 22.03%; ferric oxide (Fe 2 O 3 ) 19.16%; calcium oxide (CaO) 3.09%; magnesium oxide (MgO) 8.83%; aluminum oxide (Al 2 O 3 ) 8.54%; manganese oxide (MnO) 3.35%; titanium dioxide (TiO 2 ) 0.18%.

[0066] The calcareous material is limestone.

[0067] The mass ratio of low-grade manganese slag to calcareous material is 1.5:1.

[0068] The particle size range of the harmless granulated blast furnace manganese slag is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com