High glutamine content hydrolyzed whey protein powder with improved digestibility and preparation thereof

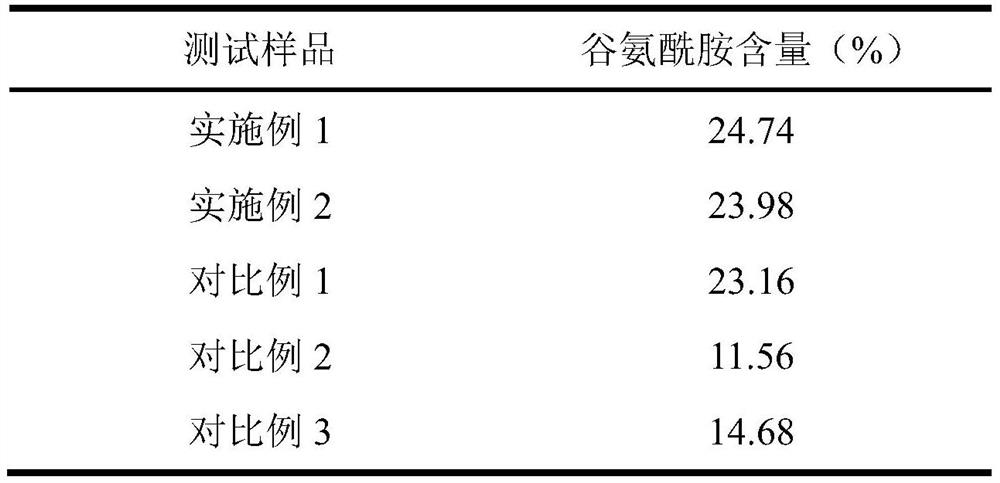

A technology of whey protein powder and whey protein, which is applied in the field of food processing, can solve problems such as low glutamine content, achieve the effects of improving digestibility, improving enzymatic hydrolysis efficiency, and improving crosslinking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

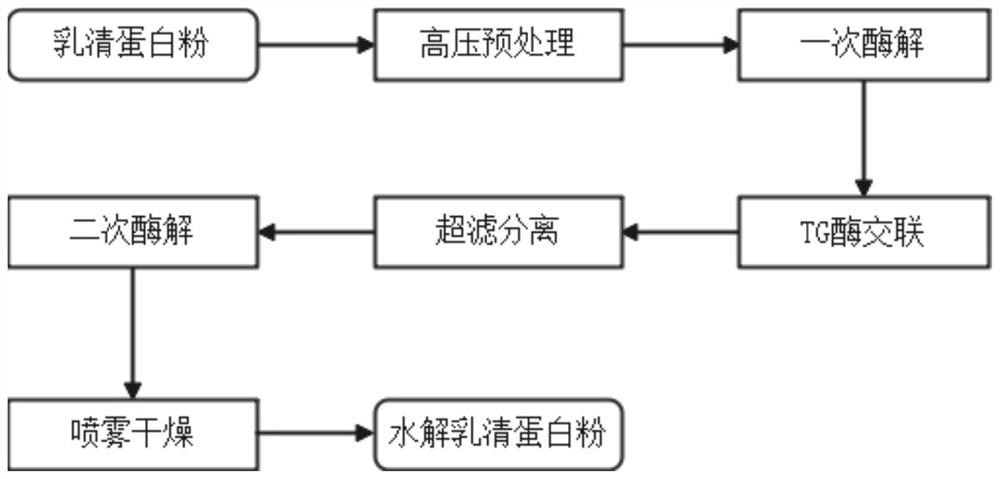

Method used

Image

Examples

Embodiment 1

[0024] (1) Stir and dissolve 5L of 20% (w / v, i.e., mass to volume g / 100mL, the same below) WPI solution, and treat with 400MPa ultra-high pressure for 30min to promote the tertiary structure of whey protein to unfold. The pH of the whey protein solution was adjusted to 7, heated to 55 °C, and 5 g of endoproteinase (1000 U / g) was added. After fully dissolving, hydrolyzed at 50 °C for 2.5 hours to obtain a hydrolyzed solution.

[0025] (2) Add 10 g of TG enzyme (120 U / g) to the primary hydrolyzate, keep the temperature at 55° C., and cross-link for 35 minutes to obtain a cross-linked glutamine-rich large molecular weight protein.

[0026] (3) Use a 20kDa ultrafiltration membrane at 10°C and a pressure of 2.5bar to intercept macromolecular glutamine-rich proteins.

[0027] (4) After redissolving the retained macromolecular protein in deionized water, a protein solution with a concentration of 18% was obtained, the pH was adjusted to 7, 3g exonuclease and 3g flavor protease were a...

Embodiment 2

[0031] (1) Stir and dissolve 6L of 25% WPI solution, after ensuring complete dissolution, use 450MPa ultra-high pressure treatment for 30min to promote the tertiary structure of whey protein to unfold. The pH of the whey protein solution was adjusted to 8, heated to 60 °C, and 12 g of endoproteinase (1000 U / g) was added. After fully dissolving, hydrolyzed at 45 °C for 2 hours to obtain an enzymatic hydrolysis solution.

[0032] (2) 18g of TG enzyme (120U / g) was added to the primary enzymolysis solution, maintained at 60° C., and cross-linked for 40 minutes to obtain a cross-linked glutamine-rich large molecular weight protein.

[0033] (3) Use a 30kDa ultrafiltration membrane at 5°C and a pressure of 3bar to intercept macromolecular glutamine-rich proteins.

[0034] (4) After re-dissolving the retained macromolecular protein, adjust the pH to 6, add 3 g of exonuclease and 9 g of flavor protease, and perform secondary enzymatic hydrolysis for 1 h at a temperature of 55°C.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com