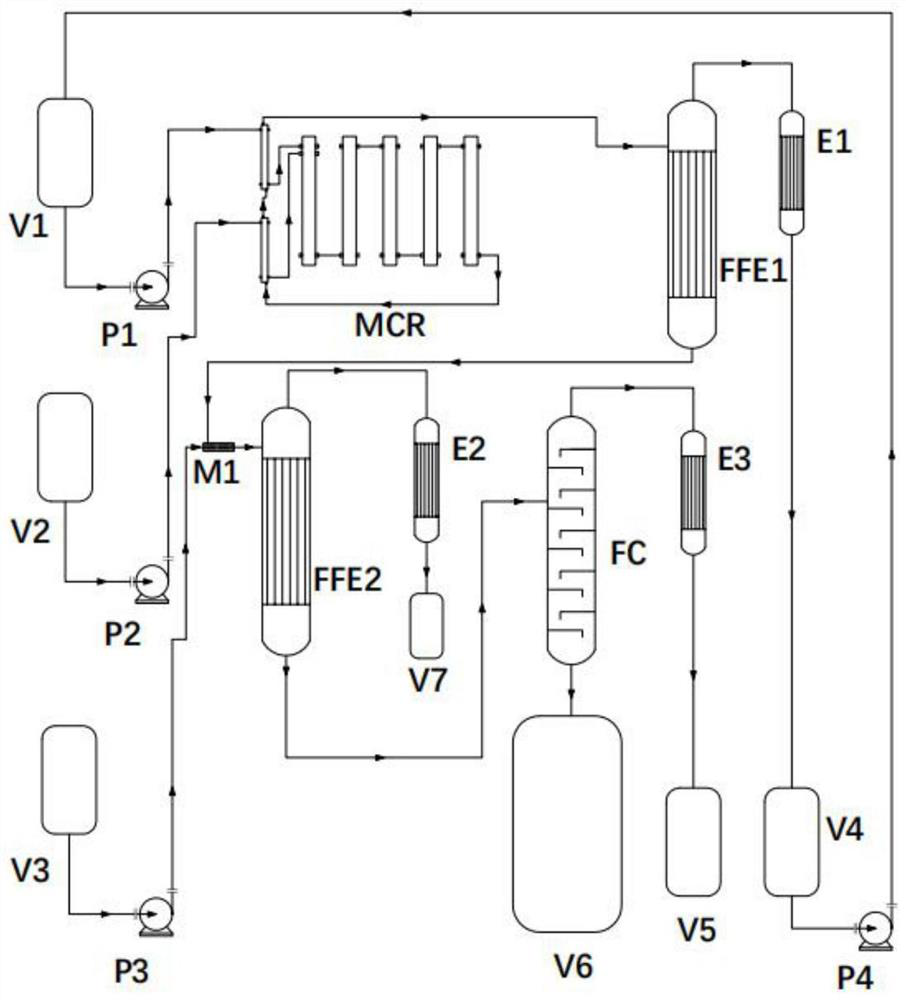

Method and device for synthesizing tetramethylammonium bicarbonate by microchannel reactor

A technology of tetramethylammonium bicarbonate and microchannel reactor, which is applied in the synthesis of tetramethylammonium bicarbonate, using a microchannel reactor to synthesize tetramethylammonium bicarbonate, can solve the problem of incomplete safety, Improve cost and floor area, corrosion of electrolysis device, etc., to achieve the effect of facilitating production expansion and efficiency increase, reducing the number of operators, and expanding production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

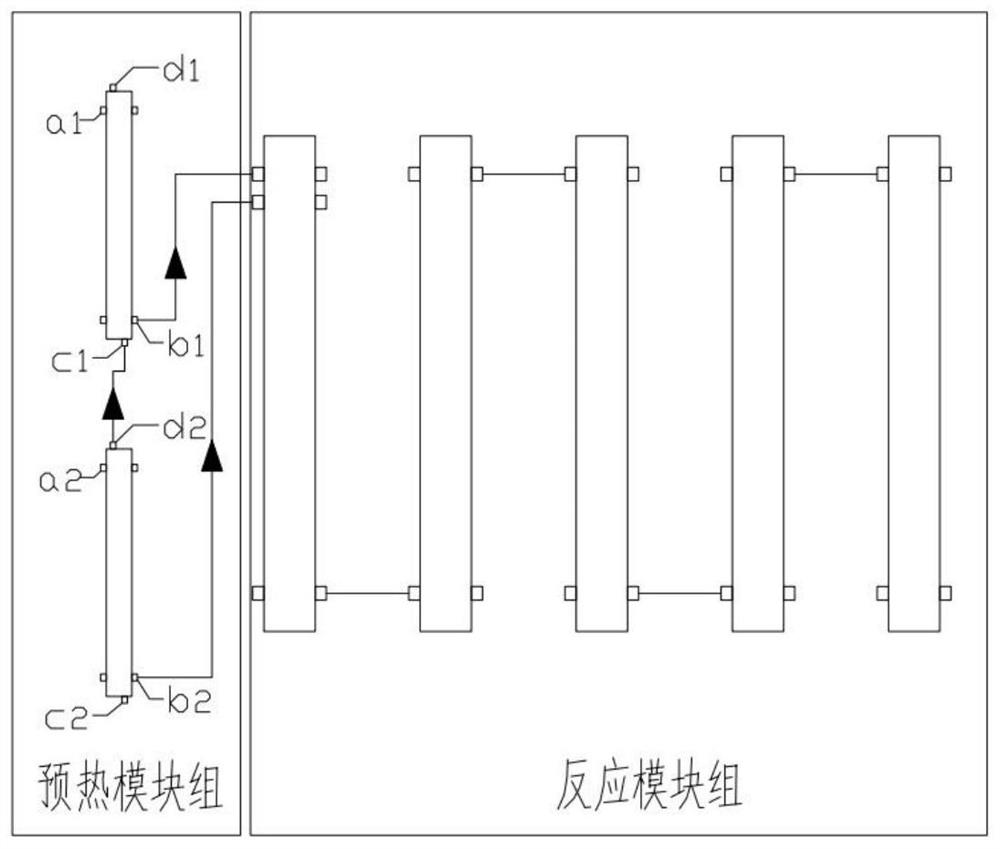

Method used

Image

Examples

Embodiment 1

[0049] The tetramethylammonium bicarbonate was synthesized through a microchannel reactor, and the raw material ratio was dimethyl carbonate and trimethylamine molar ratio = 1:1.05. The reaction pressure of the 316 stainless steel microchannel reactor was 3MPa, and the reaction temperature was 160°C. The residence time of the material in the microchannel reactor was 5 min, and the conversion rate of dimethyl carbonate was 99.0% by sampling analysis at the outlet of the reactor. The pressure of the first falling film evaporator was 0.11 MPa, and the evaporation temperature was 100°C. The pressure of the second falling film evaporator was normal pressure, and the evaporation temperature was 100°C. The pressure of the rectification tower is 0.09MPa, and the rectification temperature is 100℃. Sampling and analyzing the content of the product tetramethylammonium bicarbonate, the yield of tetramethylammonium bicarbonate was 97.3%.

Embodiment 2

[0051] The tetramethylammonium bicarbonate was synthesized through a microchannel reactor, and the raw material ratio was dimethyl carbonate and trimethylamine molar ratio = 1:1.02. The reaction pressure of the 316 stainless steel microchannel reactor was 4MPa, and the reaction temperature was 180°C. The residence time of the material in the microchannel reactor was 5 min, and the conversion rate of dimethyl carbonate was 98.8% by sampling analysis at the outlet of the reactor. The pressure of the first falling film evaporator was 0.15MPa, and the evaporation temperature was 110°C. The pressure of the second falling film evaporator was normal pressure, and the evaporation temperature was 110°C. The pressure of the rectification tower is 0.1MPa, and the rectification temperature is 110℃. Sampling and analyzing the content of the product tetramethylammonium bicarbonate, the yield of tetramethylammonium bicarbonate was 96.5%.

Embodiment 3

[0053] The tetramethylammonium bicarbonate was synthesized through a microchannel reactor, and the raw material ratio was dimethyl carbonate and trimethylamine molar ratio = 1:1.02. The reaction pressure of the 316 stainless steel microchannel reactor was 4MPa, and the reaction temperature was 180°C. The residence time of the material in the microchannel reactor was 3 minutes, and the conversion rate of dimethyl carbonate was 98.2% by sampling and analyzing the outlet of the reactor. The pressure of the first falling film evaporator was 0.12MPa, and the evaporation temperature was 110°C. The pressure of the second falling film evaporator was normal pressure, and the evaporation temperature was 110°C. The pressure of the rectification tower is 0.11MPa, and the rectification temperature is 110℃. Sampling and analyzing the content of the product tetramethylammonium bicarbonate, the yield of tetramethylammonium bicarbonate was 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com